Anaerobic and aerobic composite biological treatment desalination method

A technology of biological treatment and oxygen recombination, which is applied in the direction of biological treatment devices, biological water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problems of RO desalination technology, high operating costs, limitations of desalination efficiency, etc., to avoid water Consumption and cost rise sharply, reduce construction investment, and reduce production management and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An anaerobic + aerobic composite biological treatment desalination method, comprising the following steps:

[0045] The sewage to be treated is sequentially subjected to anaerobic reaction treatment and aerobic reaction treatment under the action of anaerobic sludge and aerobic sludge. The salt in the sewage is mixed in the anaerobic sludge and aerobic sludge in the form of inorganic salt sludge. It is discharged in the middle, and after anaerobic reaction treatment and aerobic reaction treatment, the desalted sewage is obtained;

[0046] Before the anaerobic reaction, the temperature of the sewage to be treated is controlled at 12-42°C; the pH of the anaerobic reaction is controlled to be 5.8-9. After the anaerobic reaction treatment, part of the salt in the sewage is precipitated in the form of inorganic salt sludge and mixed in the anaerobic sludge, then the anaerobic sludge is discharged, and part of it is returned to the anaerobic reaction process for recycling, wh...

Embodiment 2

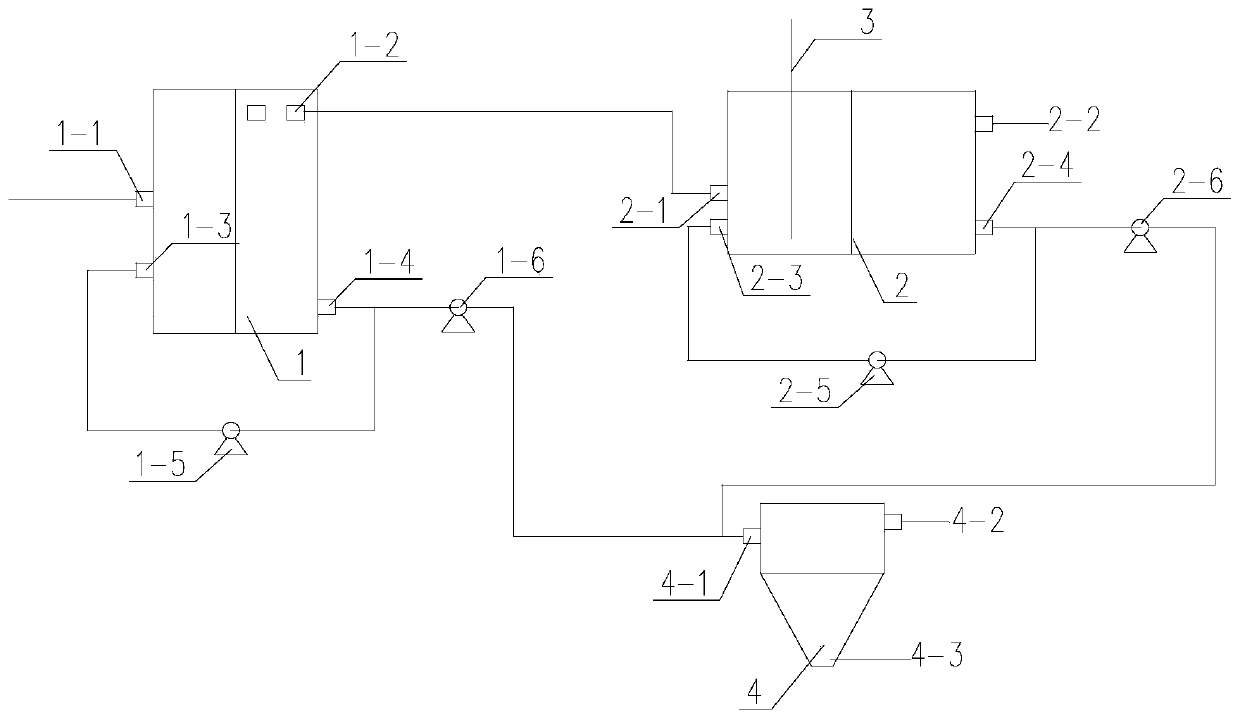

[0052] Such as figure 1 As shown, an anaerobic + aerobic compound biological treatment desalination method is carried out by using the following treatment device:

[0053] Described treatment device comprises anaerobic reactor 1, aerobic reactor 2 and settling tank 4, and described anaerobic reactor 1 is provided with the first sewage water inlet 1-1, the first sewage water outlet 1-2, The first sludge feed port 1-3, the first sludge discharge port 1-4, the aerobic reactor 2 is provided with a second sewage water inlet 2-1, a second sewage water outlet 2-2, The second sludge feed port 2-3, the second sludge discharge port 2-4, the settling tank 4 is provided with a settling tank feed port 4-1, a settling tank discharge port 4-2, a settling tank Salt discharge pipe 4-3, the aerobic reactor 2 is also provided with an air inlet pipe 3;

[0054] The first sewage water outlet 1-2 is connected to the second sewage water inlet 2-1, and the first sludge discharge port 1-4 is connect...

Embodiment 3

[0059] As described in Example 2, the difference is:

[0060] The sewage inflow temperature of the anaerobic reactor 1 is 48-60° C., and a cooling device is installed before the aerobic reactor 2 enters the water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com