Synthetic rubber and preparation method thereof

A synthetic rubber and rubber technology, applied in the field of synthetic rubber and its preparation, can solve the problems of good tensile properties and aging resistance, and achieve the effects of good aging resistance, improved tensile strength, and scientific and reasonable raw material formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

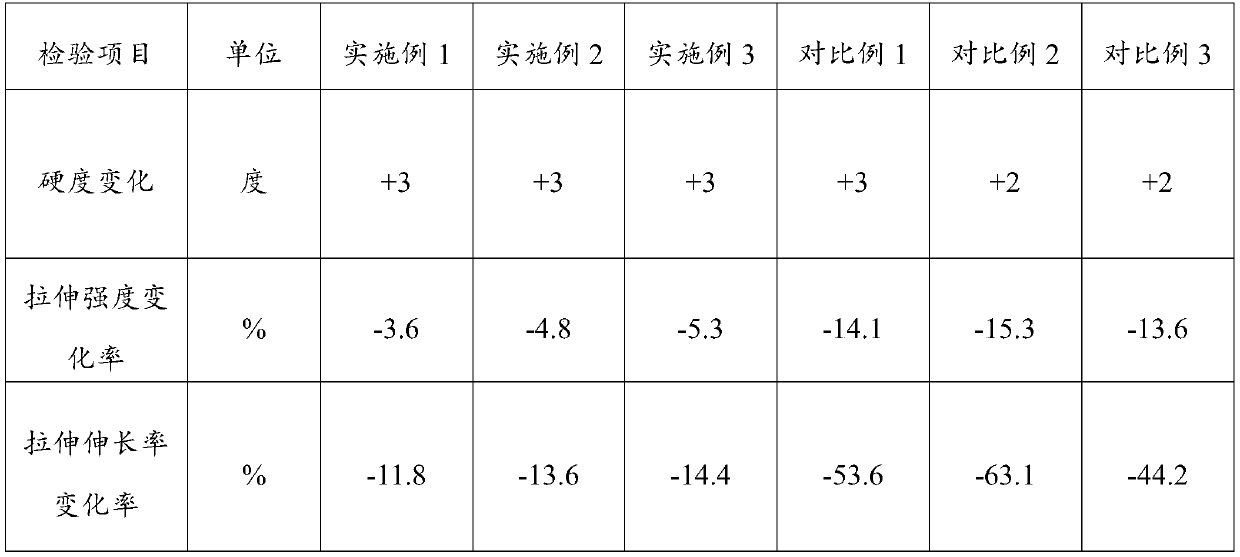

Examples

Embodiment 1

[0018] 1, the synthetic rubber of present embodiment, adopts the raw material of following parts by weight to make: 17 parts of nitrile rubbers, 13 parts of isopropyl rubbers, 9 parts of MQ resins, 7 parts of ester plasticizers, 7 parts of silane coupling agents 3 parts, 3 parts of stearic acid, 3 parts of carbon black, 1.5 parts of foaming agent, 1.5 parts of anti-aging agent, 3-5 parts of vulcanizing agent.

[0019] 2. Preparation method:

[0020] Step 1. Add 17 parts of nitrile rubber and 13 parts of isopropyl rubber into the rubber mixer for mixing, then add 7 parts of silane coupling agent and continue mixing until the mixture is uniform to obtain a slurry;

[0021] Step 2, heating the mixed slurry to 145°C, adding 3 parts of stearic acid, and kneading to obtain a mixed solution;

[0022] Step 3. After the temperature of the mixture is stable, add 9 parts of MQ resin and 7 parts of ester plasticizer, and stir evenly to obtain a semi-solid;

[0023] Step 4. Add 3 parts o...

Embodiment 2

[0025] 1, the synthetic rubber of present embodiment, adopts the raw material of following parts by weight to make: 18 parts of nitrile rubbers, 12 parts of isopropyl rubbers, 8 parts of MQ resins, 6 parts of ester plasticizers, 6 parts of silane coupling agents 2 parts, 2 parts of stearic acid, 2 parts of carbon black, 2 parts of foaming agent, 2 parts of antioxidant, 3 parts of vulcanizing agent.

[0026] 2. Preparation method:

[0027] Step 1. Add 18 parts of nitrile rubber and 12 parts of isopropyl rubber into the rubber mixer for mixing, then add 6 parts of silane coupling agent and continue mixing until the mixture is uniform to obtain a slurry;

[0028] Step 2, heating the mixed slurry to 140°C, adding 2 parts of stearic acid, and kneading to obtain a mixed solution;

[0029] Step 3. After the temperature of the mixture is stable, add 8 parts of MQ resin and 6 parts of ester plasticizer, and stir evenly to obtain a semi-solid;

[0030] Step 4. Add 2 parts of carbon bl...

Embodiment 3

[0032] 1, the synthetic rubber of present embodiment, adopts the raw material of following parts by weight to make: 16 parts of acrylonitrile-butadiene rubber, 15 parts of isopropyl rubber, 10 parts of MQ resin, 8 parts of ester plasticizers, 8 parts of silane coupling agent 4 parts, 4 parts of stearic acid, 4 parts of carbon black, 4 parts of foaming agent, 4 parts of antioxidant, 5 parts of vulcanizing agent.

[0033] 2. Preparation method:

[0034] Step 1. Add 16 parts of nitrile rubber and 15 parts of isopropyl rubber into the rubber mixer for mixing, then add 8 parts of silane coupling agent and continue mixing until the mixture is uniform to obtain a slurry;

[0035] Step 2, heating the mixed slurry to 150°C, adding 4 parts of stearic acid, and kneading to obtain a mixed solution;

[0036] Step 3. After the temperature of the mixture is stable, add 10 parts of MQ resin and 8 parts of ester plasticizer, and stir evenly to obtain a semi-solid;

[0037] Step 4. Add 4 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com