A cantilever type girder lifting system with a tower attached to a mountainous area

A cantilever type and truss crane technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the inability to use conventional tower cranes for high-altitude hoisting, achieve complete functions, improve stability and reliability, and save costs and time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

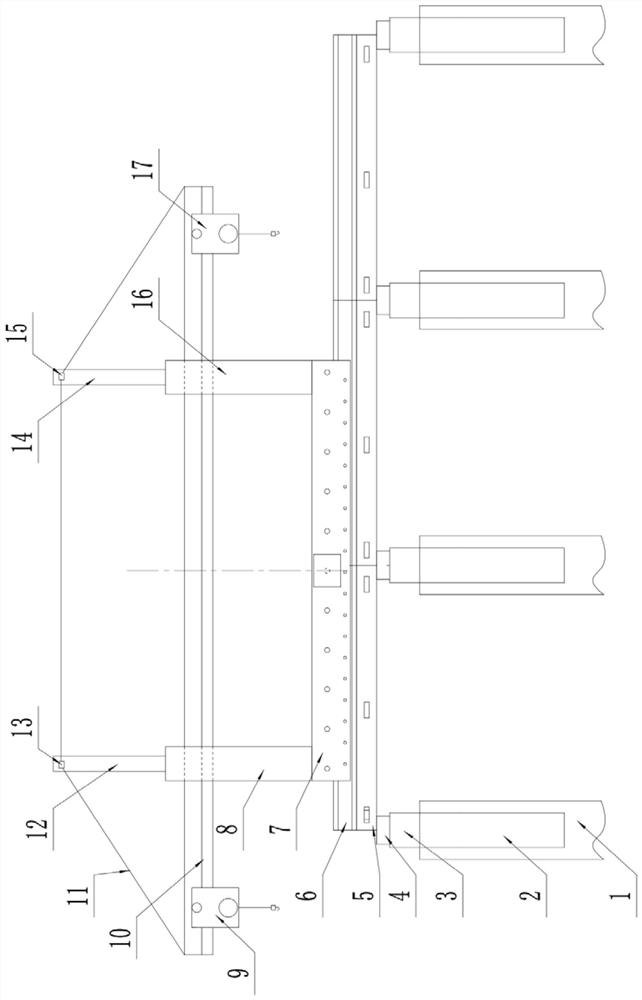

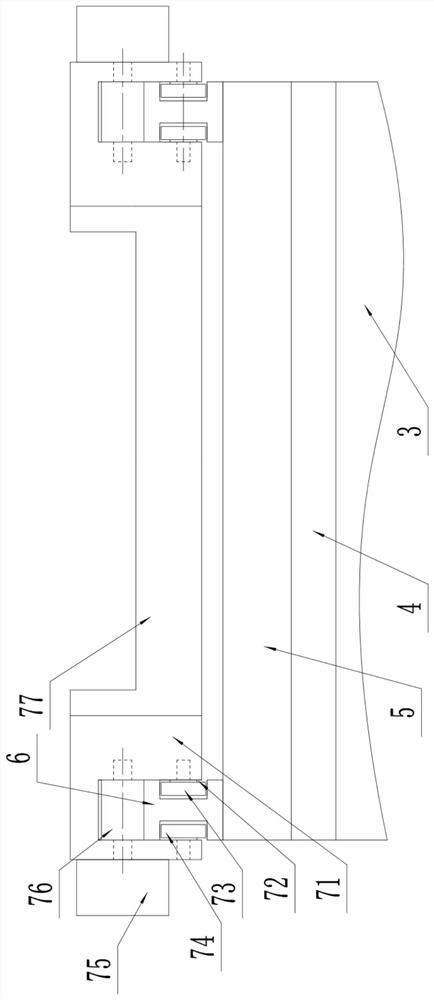

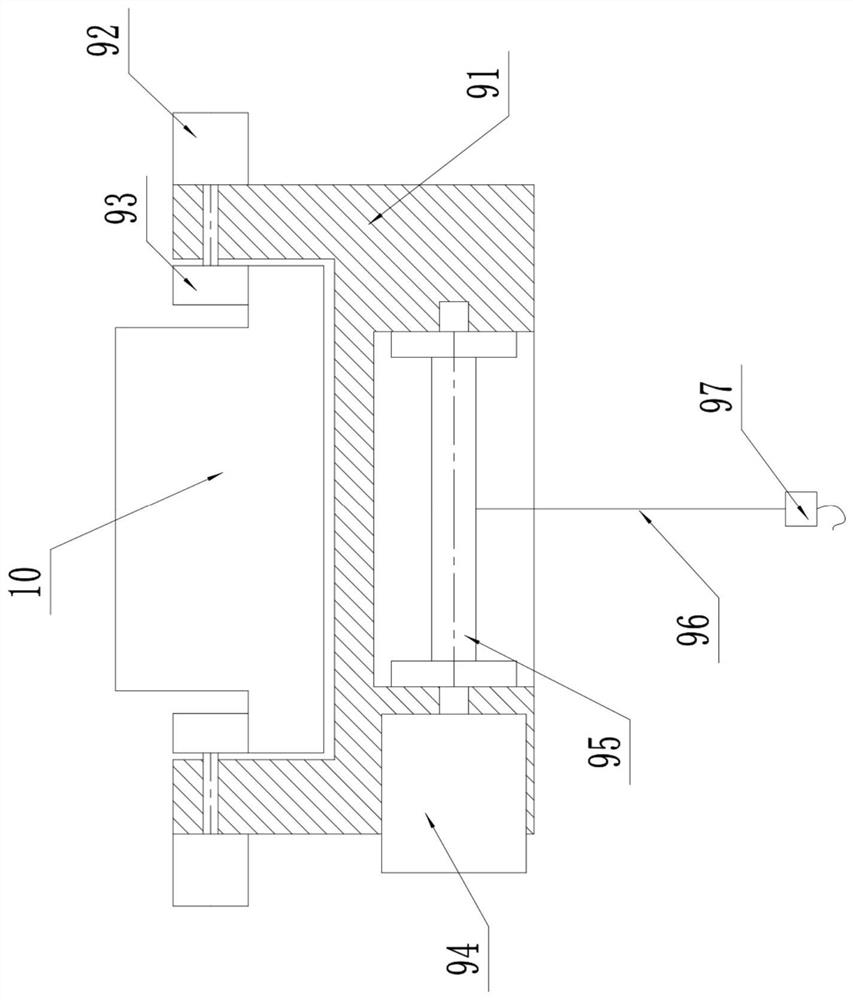

[0021] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a cantilever-type girder lifting system with a tower attached to a mountainous area, including a tower column 1, and also includes a cantilever support seat 2, a connecting seat 3, a pad 4, a support plate 5, and a guide rail 6. Supporting walking mechanism 7, truss crane bracket 1 8, walking lifting mechanism 1 9, truss crane beam 10, pull rope 11, column 1 12, fixed block 1 13, column 2 14, fixed block 2 15, truss crane Support two 16 and walking lifting mechanism one 17; the cantilever support base 2 is several, and the cantilever support base 2 is respectively fixedly connected on the same side of the tower column 1; the connection base 3 is several, and the bottom of the connection base 3 They are respectively fixedly connected to the tops of the corresponding cantilever support seats 2; the pads 4 are several, and the bottoms of the pads 4 are respectively fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com