Onboard minitype high-pressure compressor

A high-pressure compressor and miniature technology, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve problems such as increased compressor pressure ratio, poor heat dissipation conditions, and reduced intake mass flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the embodiments described below are only illustrative and not restrictive.

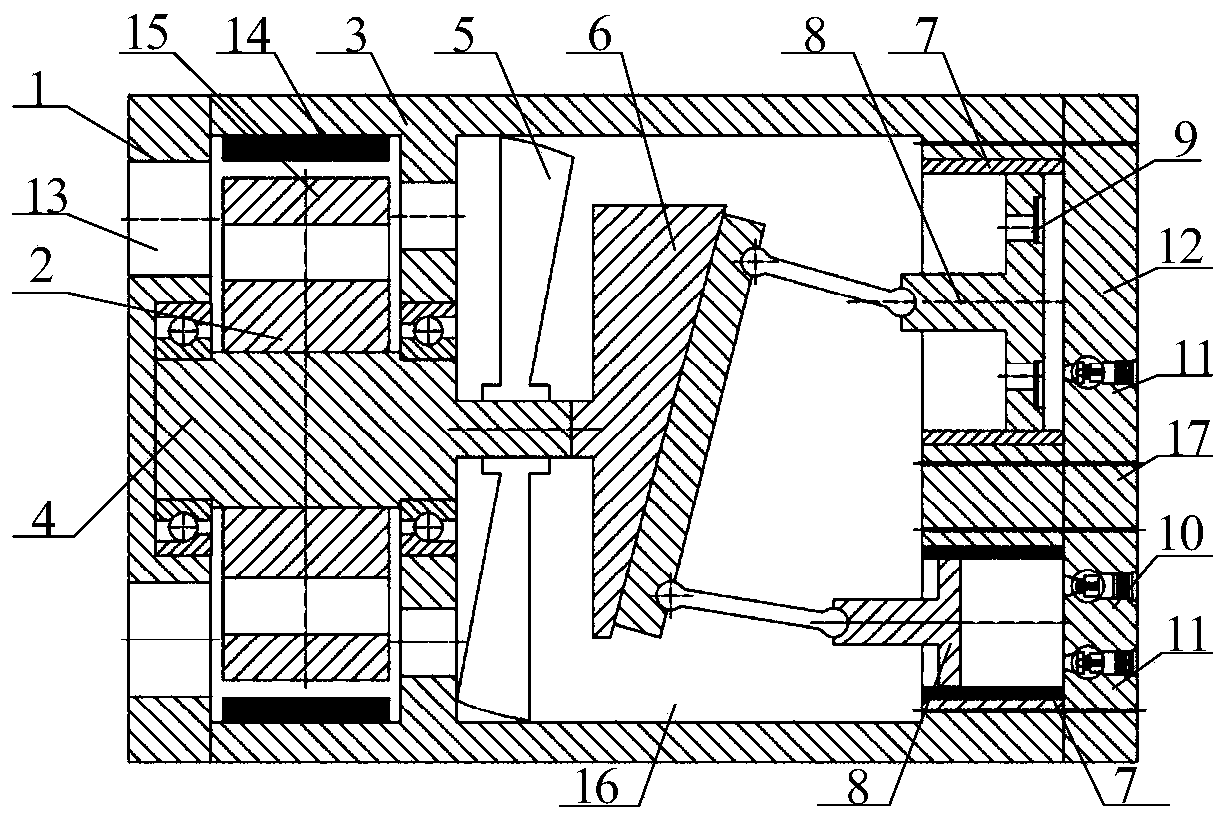

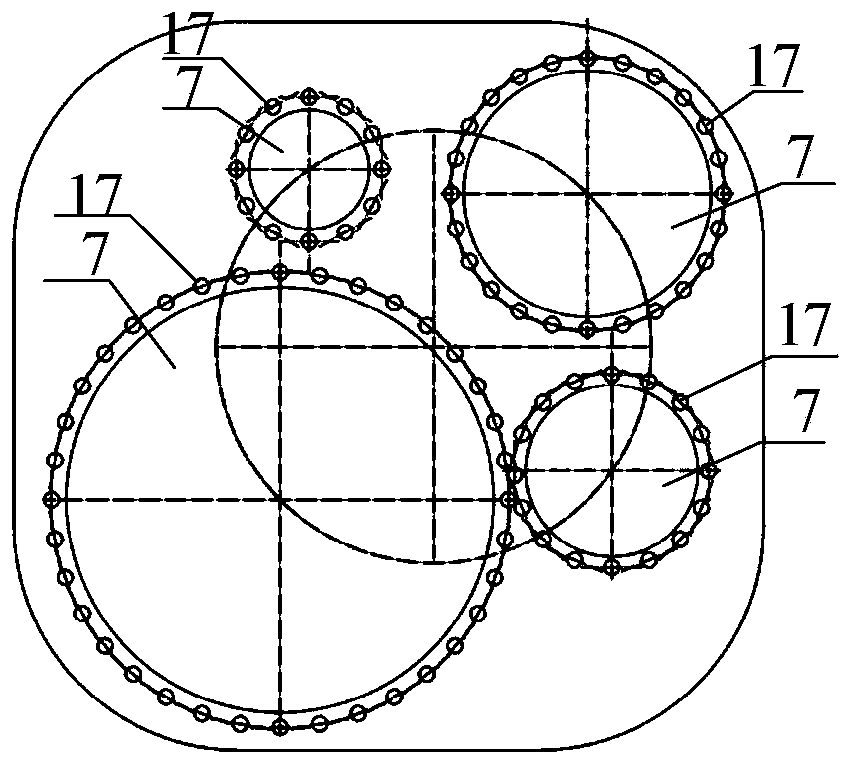

[0011] like figure 1 As shown, the airborne miniature high-pressure compressor includes: end cover 1, motor 2, casing 3, transmission shaft 4, wind wheel 5, swash plate plunger 6, cylinder 7, piston 8, reed valve 9, intake one-way Valve 10, exhaust check valve 11 and valve plate 12.

[0012] like figure 1 As shown, a plurality of air intake holes 13 are processed on the end cover 1, and the end cover 1 is connected with the housing 3 through bolts, and the end cover 1 can also provide rotary support for the transmission shaft 4 through bearings.

[0013] like figure 1 As shown, the motor 2 adopts a permanent magnet DC synchronous motor, which is mainly composed of a motor stator 14 and a motor rotor 15. The motor stator 14 is direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com