Heating module, heating module set and electric heating radiator

A heating module and electric heating technology, which is applied in household heating, heating methods, electric heating systems, etc., can solve the problems of troublesome product assembly, high energy consumption, and high temperature of electric radiators, so as to improve heat dissipation speed and heat dissipation efficiency, The effect of increasing the heat dissipation area and ensuring air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

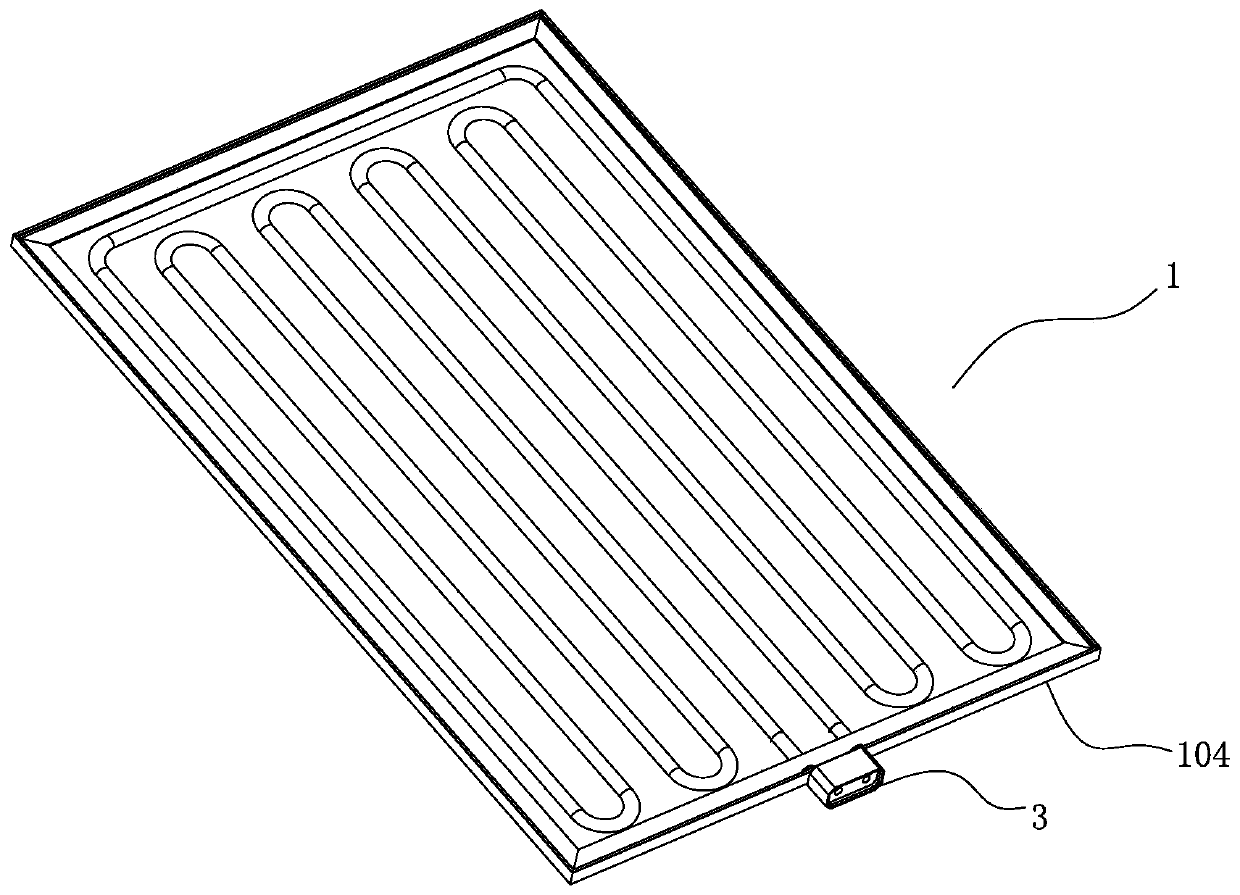

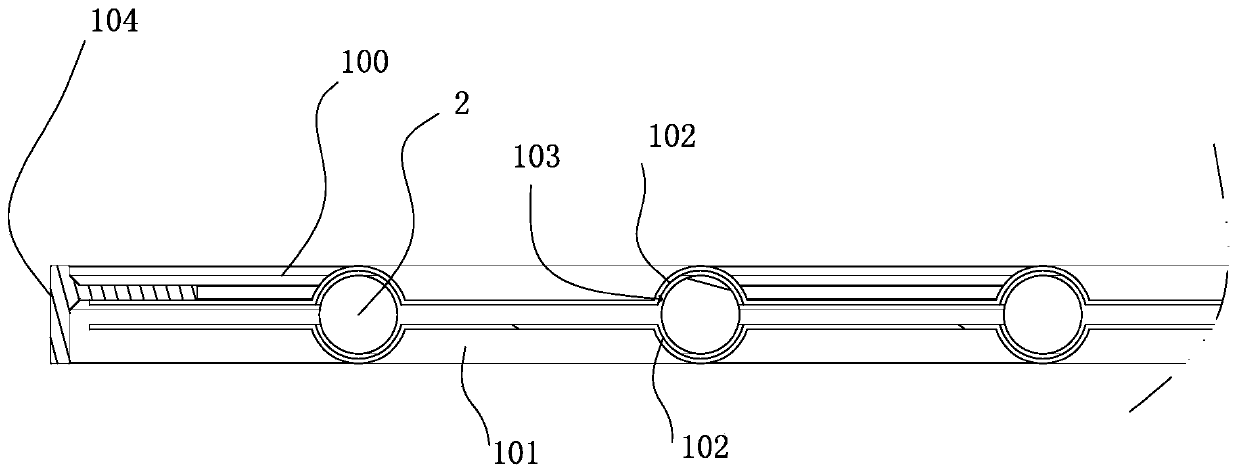

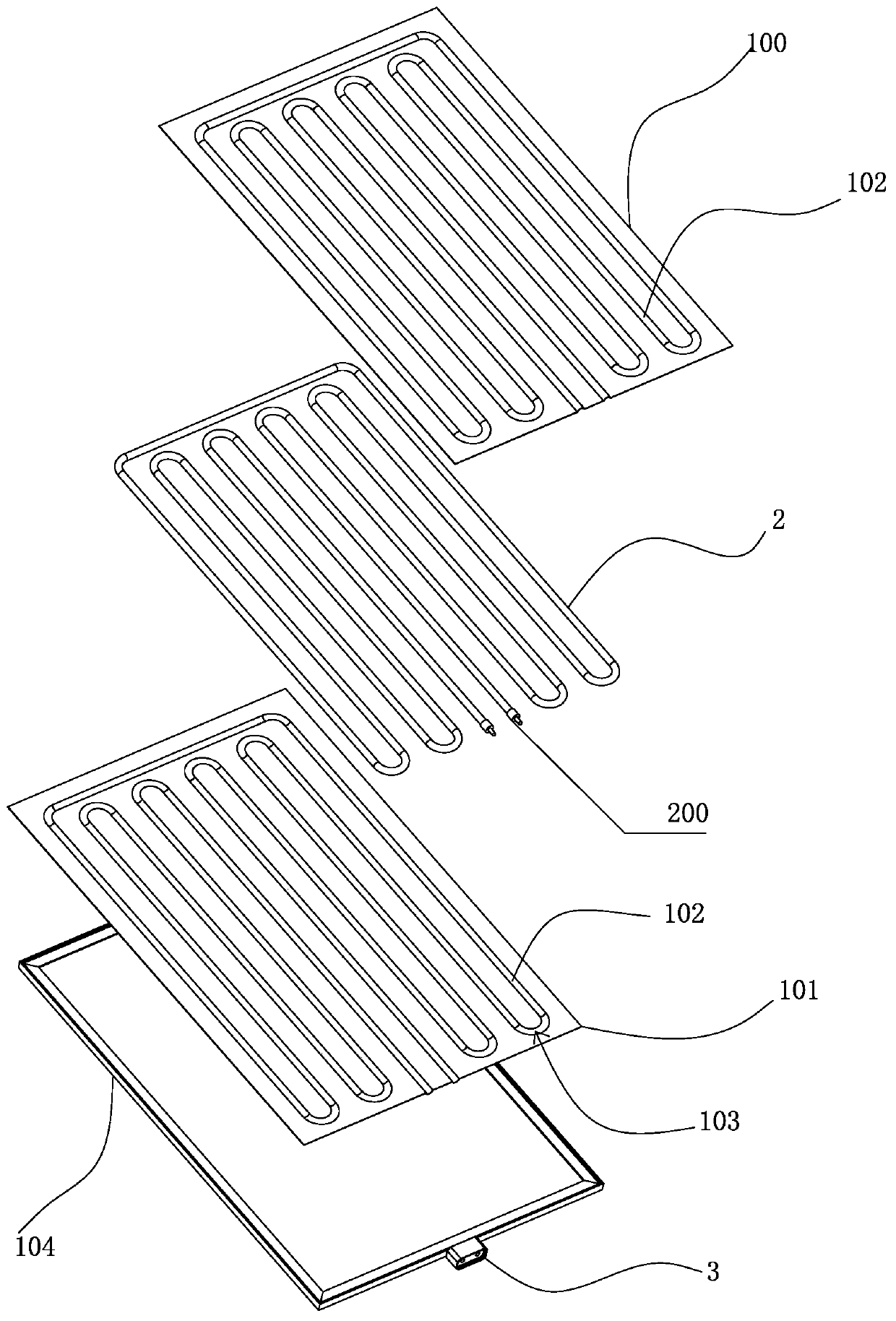

[0045] See Figure 1 ~ Figure 3 As shown, a heating module 1 of the present invention includes a heating element 2 and has a conductive end 200; the heating element 2 is a prior art product, which can be a heating wire made of nickel-chromium alloy wire or a heating wire. Diaphragm, PTC heating element, etc., whose conductive end 200 is connected to the heating element to generate heat when the heating element is energized. Two oppositely arranged heat sinks: a first heat sink 100 and a second heat sink 101. The first heat sink 100 and the second heat sink 101 are made of aluminum plates with good thermal conductivity. The heat sink material can also be Mica board, gypsum board, etc., which are used for heat dissipation. The opposite inner side walls of the first heat sink 100 and the second heat sink 101 are both provided with recessed accommodatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com