Measurement device and method for quantitatively representing drying and curing time of emulsion colloid

A quantitative characterization and curing time technology, applied in the investigation stage/state change and other directions, can solve the problems of not having clear guiding significance, insufficient to characterize the curing time of the colloid drying state, etc., to achieve a simple and fast method, rapid determination, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

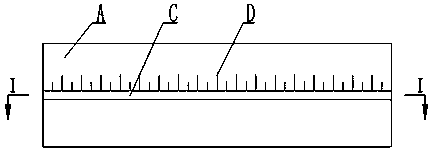

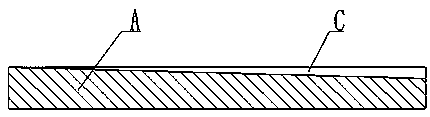

[0024] The described measuring device for quantitatively characterizing the drying and curing time of the emulsion colloid comprises: a measuring plate A and a scraper B; the measuring plate A is provided with a depth along the length direction of the measuring plate A which gradually changes from deep to zero. Groove C, the inclination of the bottom surface of groove C is 15°~30°; the wall surface of groove C must be smooth, clean and dry. To ensure that the test film formed by the emulsion colloid is uniform and continuous, so as to ensure the accuracy of the measurement results.

[0025] The roughness of the contact surface between the scraper B and the measuring board A and the surface where the groove of the measuring board A is located is: Ra is less than 0.3 μm, so as to ensure its smoothing effect. A film is formed in the groove C to prevent the emulsion colloid from leaking out of the groove C, or the thickness of the formed test film is higher than that of the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com