Garlic sowing machine

A planter and garlic technology, which is applied in the field of agricultural machinery, can solve the problems of low seed germination rate, decreased land yield, and affect the sowing quality of the planter, and achieves the effects of ensuring the germination rate, ensuring the yield, and improving the sowing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

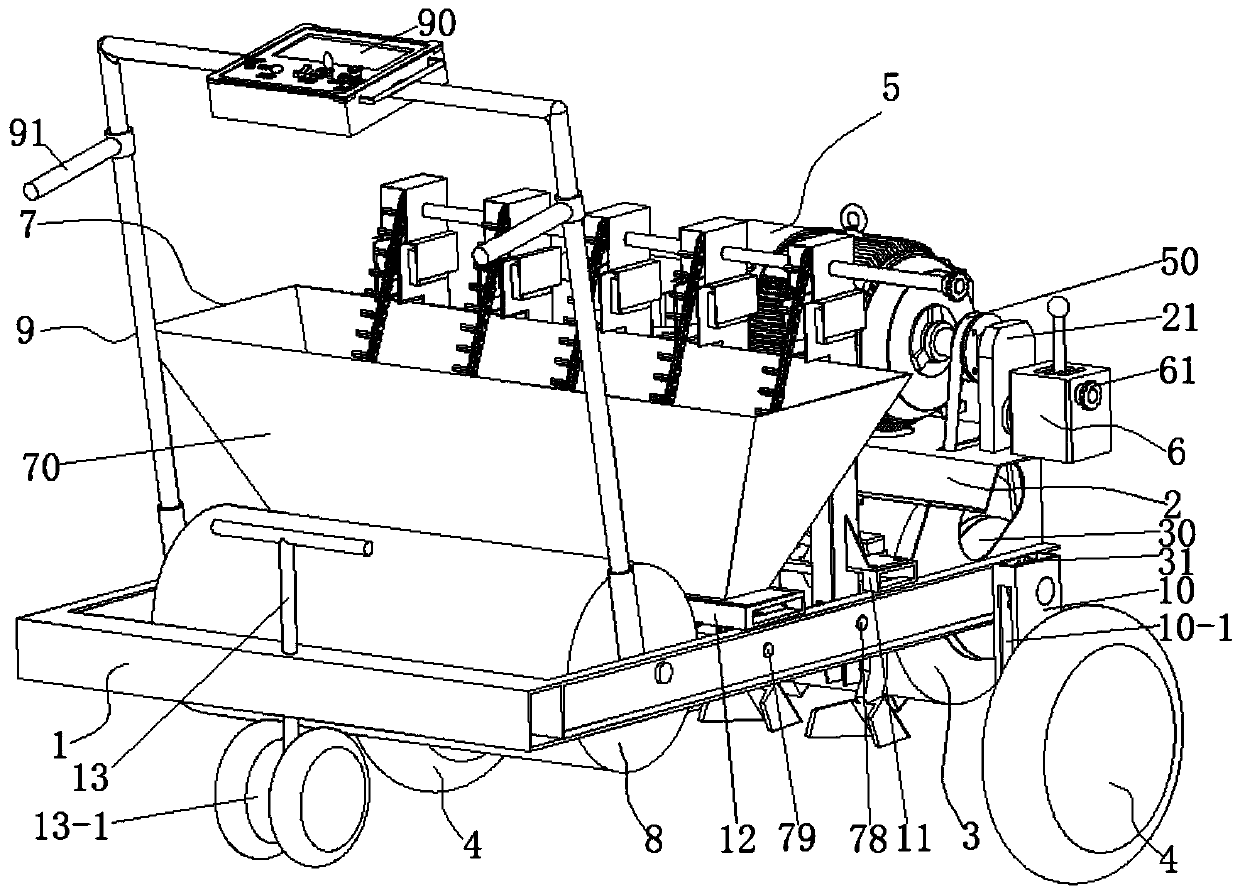

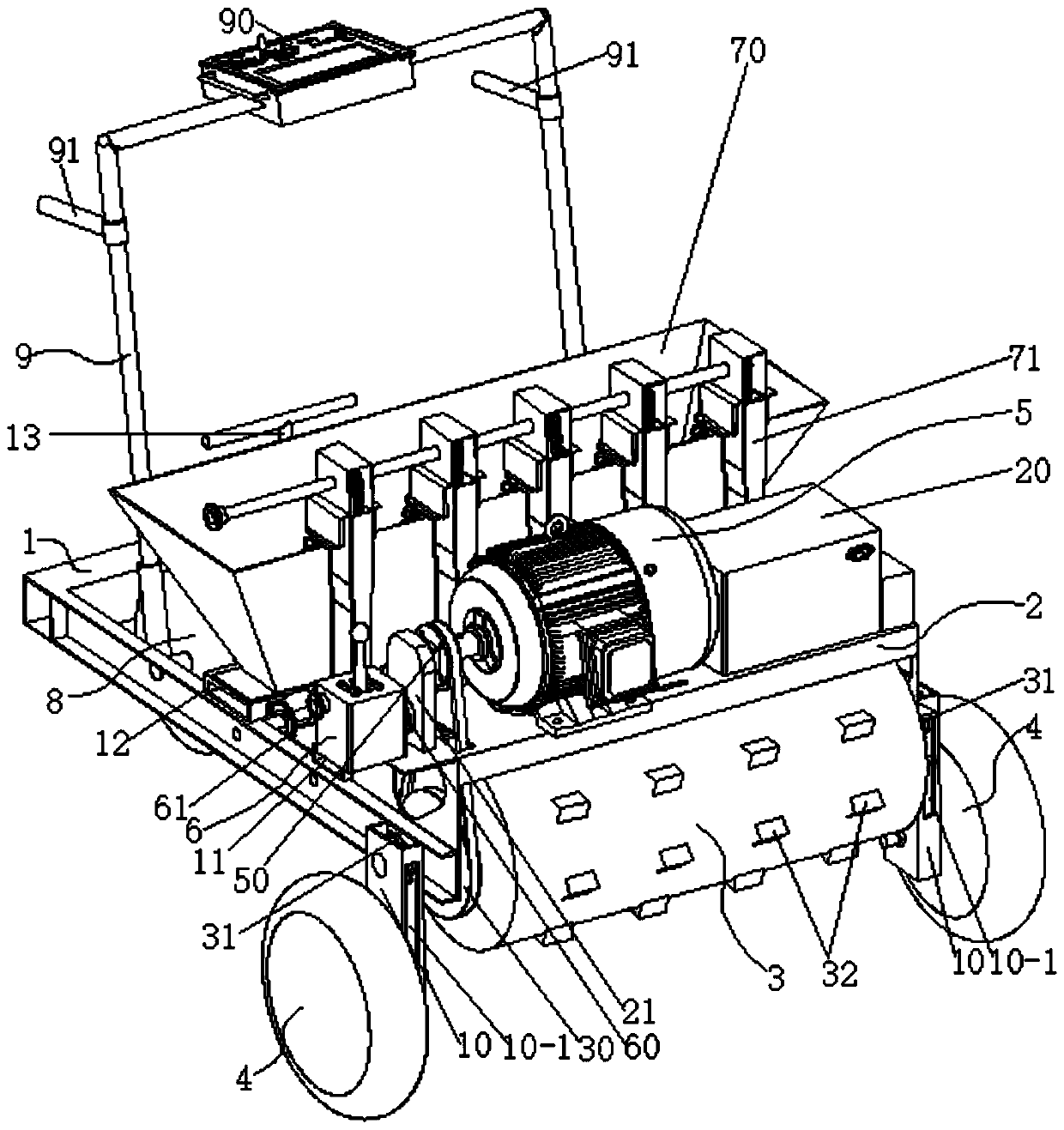

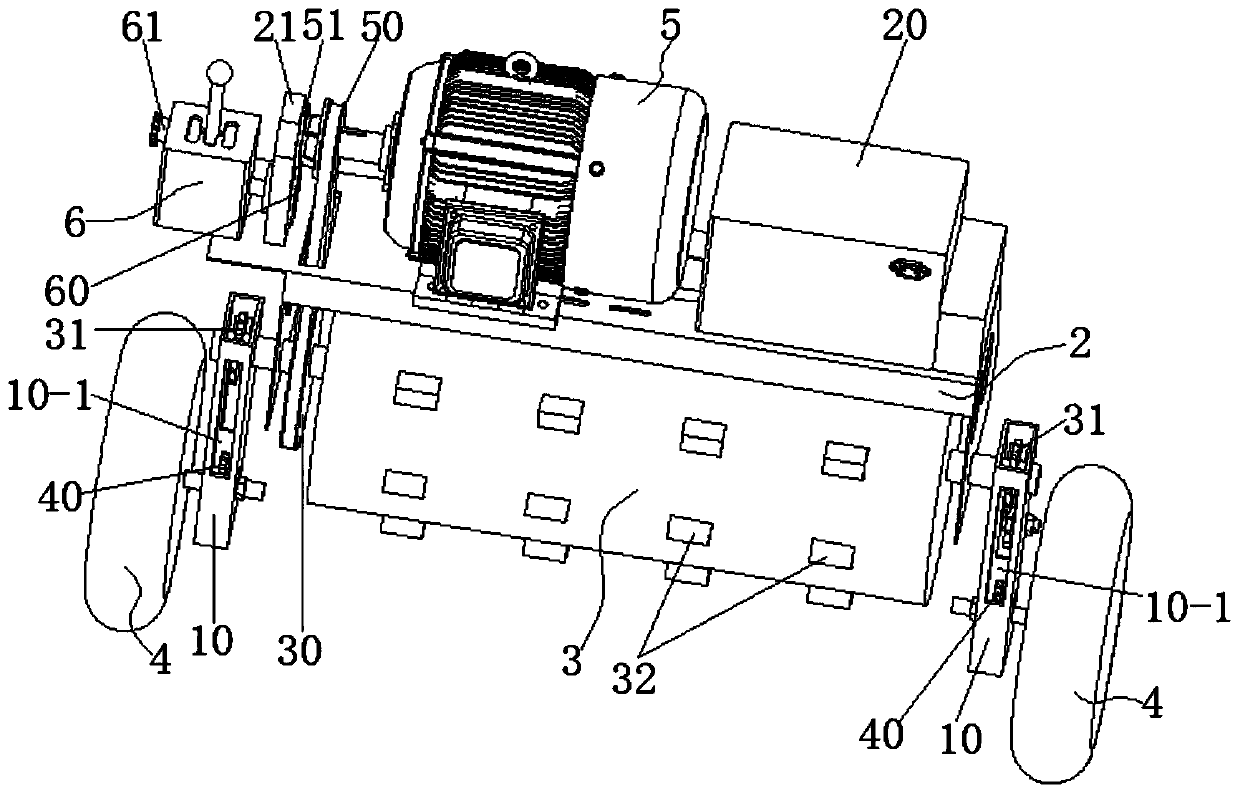

[0055] In this garlic seeder, the stripped garlic seeds are first loaded into the seed box 70. Since the seed box 70 is an inverted hollow quadrangular platform structure, the garlic seeds are all concentrated near the opening 12-3, and then passed through the armrest frame. The control box 90 in the middle of 9 starts the motor 5, the output shaft of the motor 5 drives the small pulley 50 and the gear one 51 to rotate at the same time, the power output from the motor 50 all the way small pulley 50 drives the large pulley 30 to rotate through the belt, and the large pulley 30 rotates with balance wheel 3 and sprocket wheel one 31 at balance wheel 3 two ends, and sprocket wheel one 31 rotates by chain drive sprocket two 40, and sprocket wheel two 40 drives the drive wheel 4 rotations of both sides simultaneously, and described frame 1 The middle part of the rear end rotates and is provided with a steering rod 13, and the lower end of the steering rod 13 is provided with a steeri...

Embodiment 2

[0060] On the basis of Embodiment 1, in this garlic seeder, the seeding spoon 700-1 is opened from bottom to top along with the seeding chain 700 and passes through the slot 12-3 on the rubber pad 12-2, and the seed The garlic seeds in the box 70 are taken away, and the garlic seeds contained by the seed picking spoon 700-1 move into the upper cover 72 along with the seeding chain 700, and then fall from the seed drop tube 71, because the upper end of the seed drop tube 71 The rectangular cross-section is thick, the rectangular cross-section at the lower end is thin, and the middle part is excessively connected by a hollow quadrangular platform. When the garlic seeds fall from top to bottom, they pass through the transitional area of the inverted hollow quadrangular platform in the middle, so that the bottom of the garlic seeds faces downward. , Realize the precise planting of garlic seeds with the bottom facing down, ensure the contact area between the bottom of garlic seeds...

Embodiment 3

[0062] On the basis of Example 1, the garlic planter travels to the reclaimed field, makes the two drive wheels 4 located in the drainage ditches on both sides of the sowing area, and makes the balance wheel 3 contact with the sowing area, so that the two drive wheels 4 is in a suspended state, and then adjust the support height of the steering wheel 13-1 through the steering rod 13, so that the pressure roller 8 is also in contact with the sowing area, so that the garlic planter relies on the balance wheel 3 to travel between the fields, and the balance wheel 3 and the pressure roller 8. It has a certain width, which ensures the horizontality of the garlic seeder when it is running in the field, and avoids the dropping and inclination of the seeds in the seed picking spoon 700-1 caused by the wheels supporting it when it is walking in the field. The germination rate of garlic seeds ensures the output; in addition, the traditional single-cylinder gasoline engine drive is change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com