Cleaning device for tracheotomy metal casing

A metal sleeve and tracheotomy technology, which is applied in the direction of using liquid cleaning methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of tracheotomy metal sleeves, poor cleaning efficiency, and inconvenient cleaning. To achieve the effect of guaranteeing the scrubbing effect, ensuring the cleaning effect and improving the cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

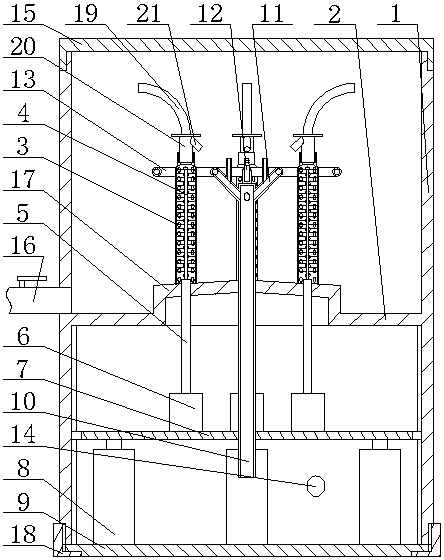

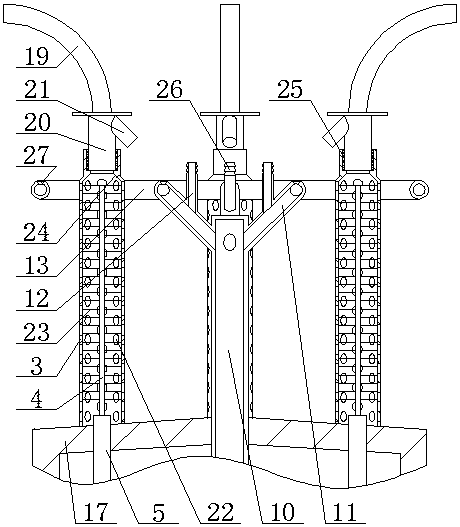

[0029] Such as Figure 1~Figure 2It can be seen that the cleaning device of the tracheotomy metal sleeve of the present invention comprises a barrel body 1, the middle part of the barrel body 1 is provided with a dividing plate 2, and the dividing plate 2 divides the barrel body 1 into an upper cleaning chamber and a lower cleaning chamber. The top surface of the partition plate 2 is fixed with a plurality of cleaning standpipes 3, and the middle part of the structure surrounded by the cleaning standpipes 3 is also fixedly provided with a water inlet standpipe 10 on the partition plate 2, and the gas pipe The 20 of the intake main pipe that cuts the metal sleeve 19 is inserted and fixed in the top port of the cleaning standpipe 3, and the cleaning standpipe 3 is provided with a flexible shaft 4 along the axial direction of the cleaning standpipe 3. The diameter of the shaft 4 is smaller than the inner diameter of the tracheotomy metal sleeve 19, and the surface of the flexible...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap