An automatic magnetic particle grinding and polishing machine for the inner wall of a vascular stent tube driven by a double magnetic pole pair electromagnet

A vascular stent and magnetic drive technology, applied in grinding/polishing equipment, machine tools for surface polishing, machine tools suitable for grinding the edge of workpieces, etc., can solve the problem of inability to uniformly remove and polish the inner wall surface, large length, and slender tubes Small diameter and other problems, to achieve the effect of uniform trace and high-efficiency mirror polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

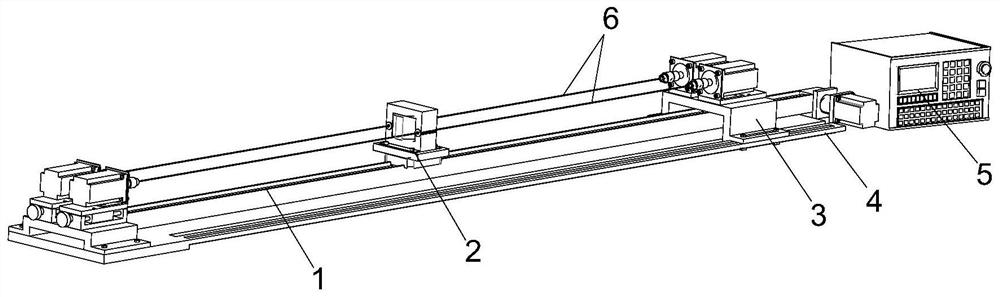

[0021] like figure 1 As shown, the overall structure of the present invention includes an electromagnet moving transmission device 1 , a DC electromagnet 2 , a vascular stent tube clamping and rotating drive device 3 , a machine base 4 and a numerical control system 5 .

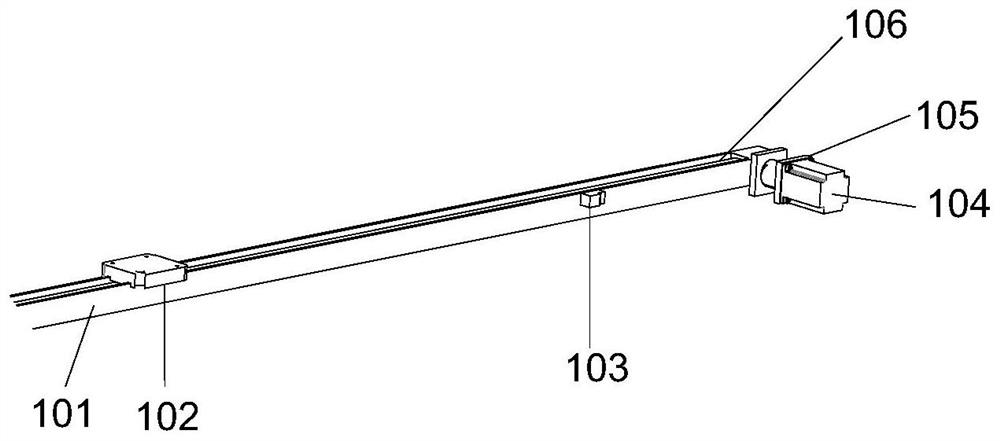

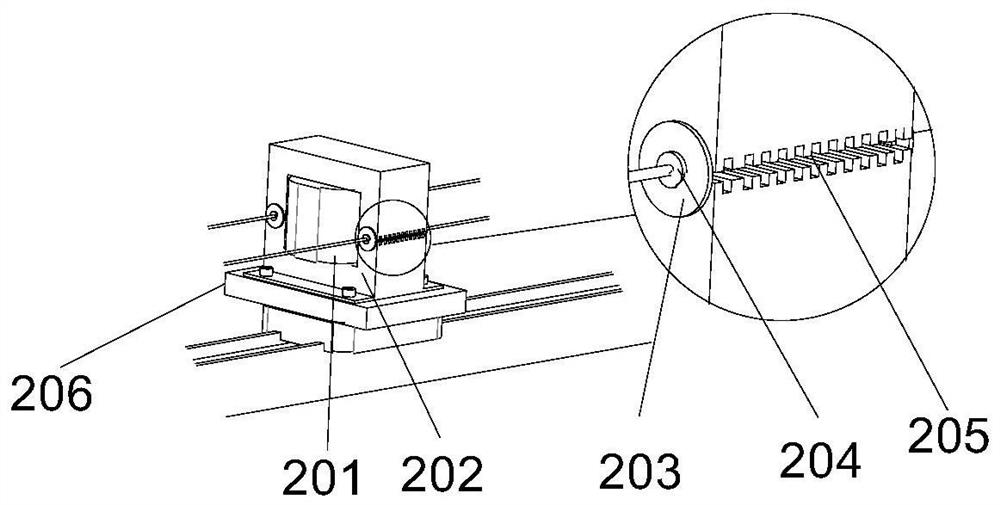

[0022] like figure 2As shown, the electromagnet mobile transmission device 1 is composed of a synchronous belt guide rail 101, a slide table 102, a limit switch 103, a stepping motor 104, a motor flange seat 105, a coupling and a synchronous belt 106; the synchronous belt guide rail 101 is fixed on On the base 4, the stepper motor 104 is fixed on the end of the synchronous belt guide rail 101 through the motor flange seat 105; the slide table 102 is installed on the synchronous belt guide rail 101 and connected to the synchronous belt 106; On the table 102; the limit swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com