A variable reluctance magnetorheological damper

A magneto-rheological damper and variable reluctance technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of strong heat generation, unstable damping characteristics of magnetorheological fluid, and restrictions on magnetic flow damping In order to reduce heat generation, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

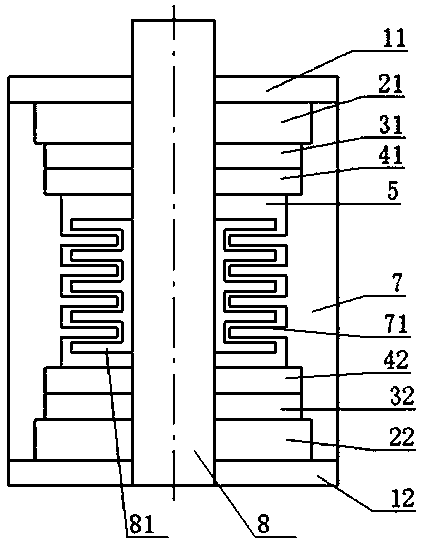

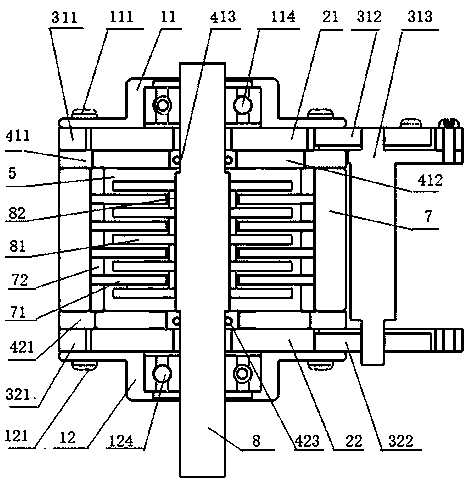

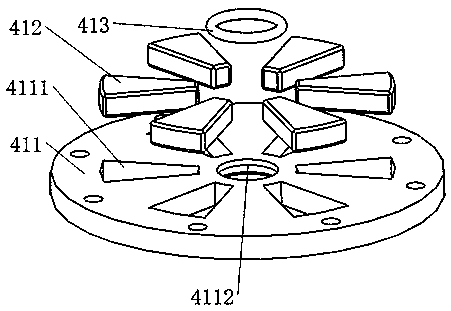

[0026] Such as figure 1 As shown, a variable reluctance magnetorheological damper according to an embodiment of the present invention includes a housing 7, an upper cover plate 11, a lower cover plate 12, an upper permanent magnet 21, a lower permanent magnet 22, a first reluctance adjustment plate 31 , second reluctance adjusting plate 32 , third reluctance adjusting plate 41 , fourth reluctance adjusting plate 42 , transmission shaft 8 , movable damping sheet group 81 and fixed damping sheet group 71 . The upper cover plate 11 is fixedly connected to the top of the housing 7, the lower cover plate 12 is fixedly connected to the bottom end of the housing 7, the two ends of the transmission shaft 8 pass through the housing 7, and are connected to the upper cover plate 11 and the lower cover plate 12 rotatable connections. The third relucta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com