Smart grinding and polishing machine for semiconductor materials

A semiconductor and polishing machine technology, used in grinding/polishing equipment, grinders, belt grinders, etc., can solve problems such as trouble, achieve the effect of convenient use and reduce manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

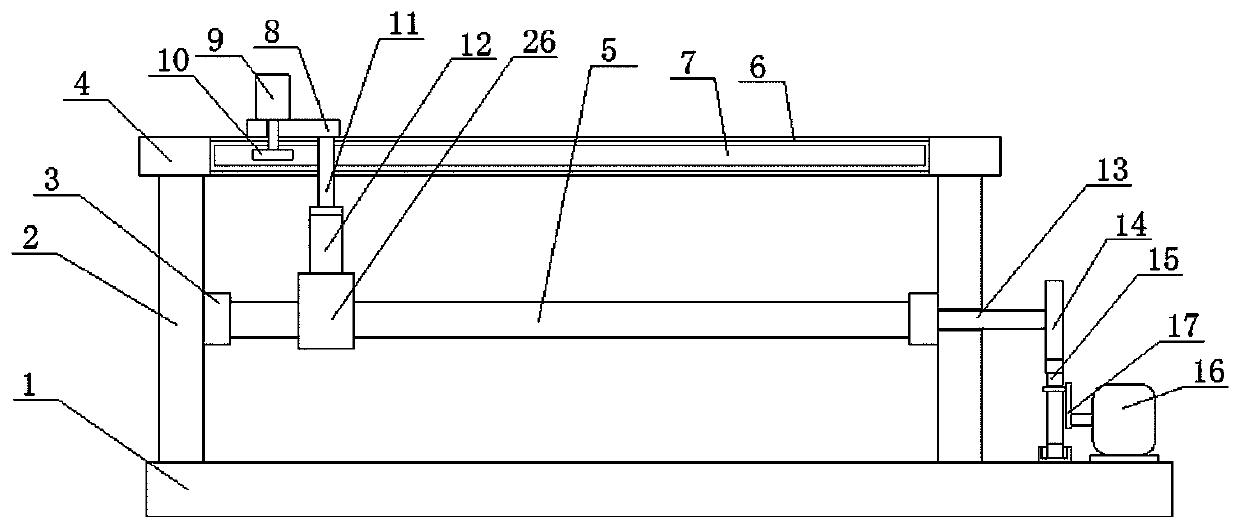

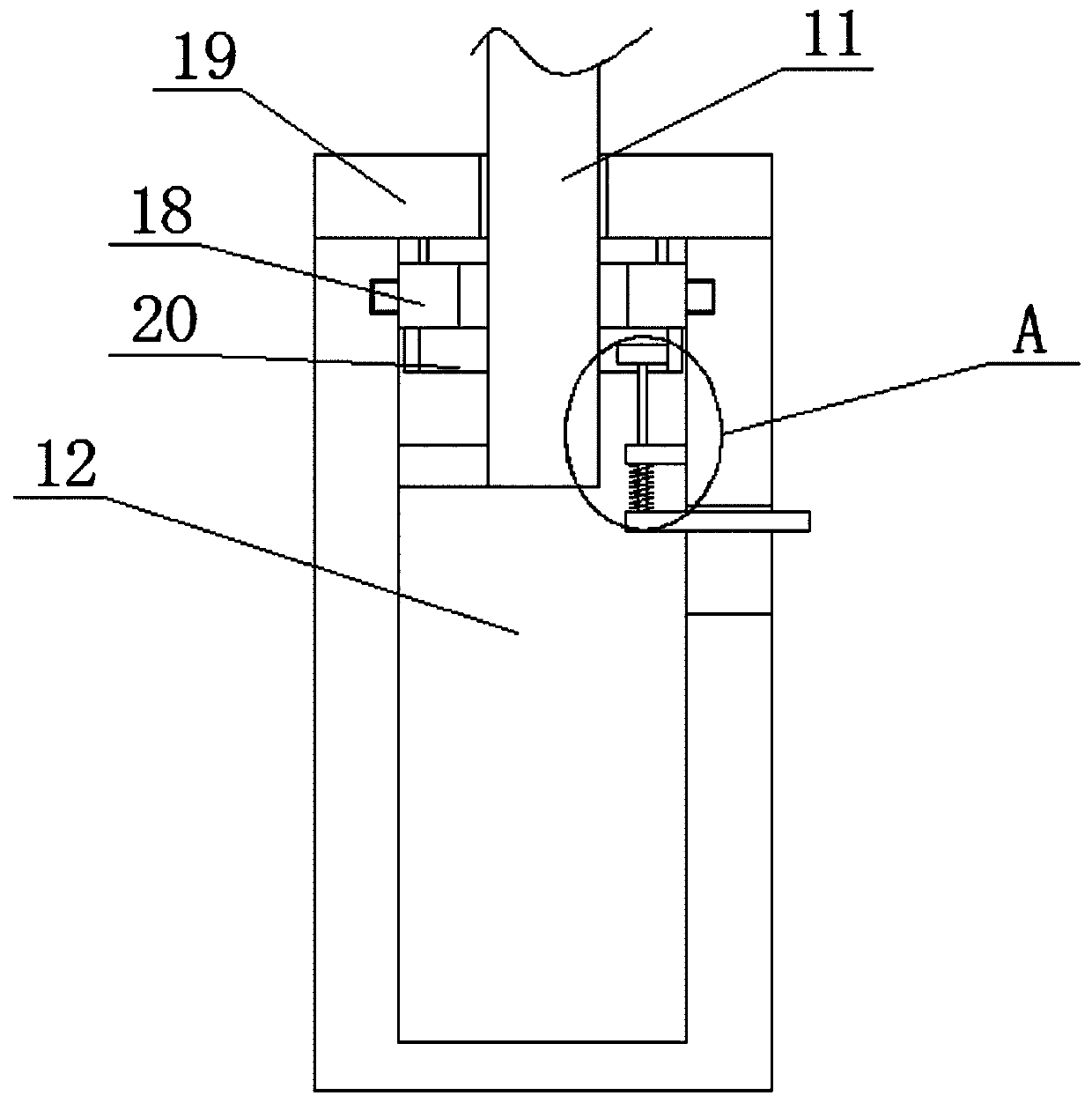

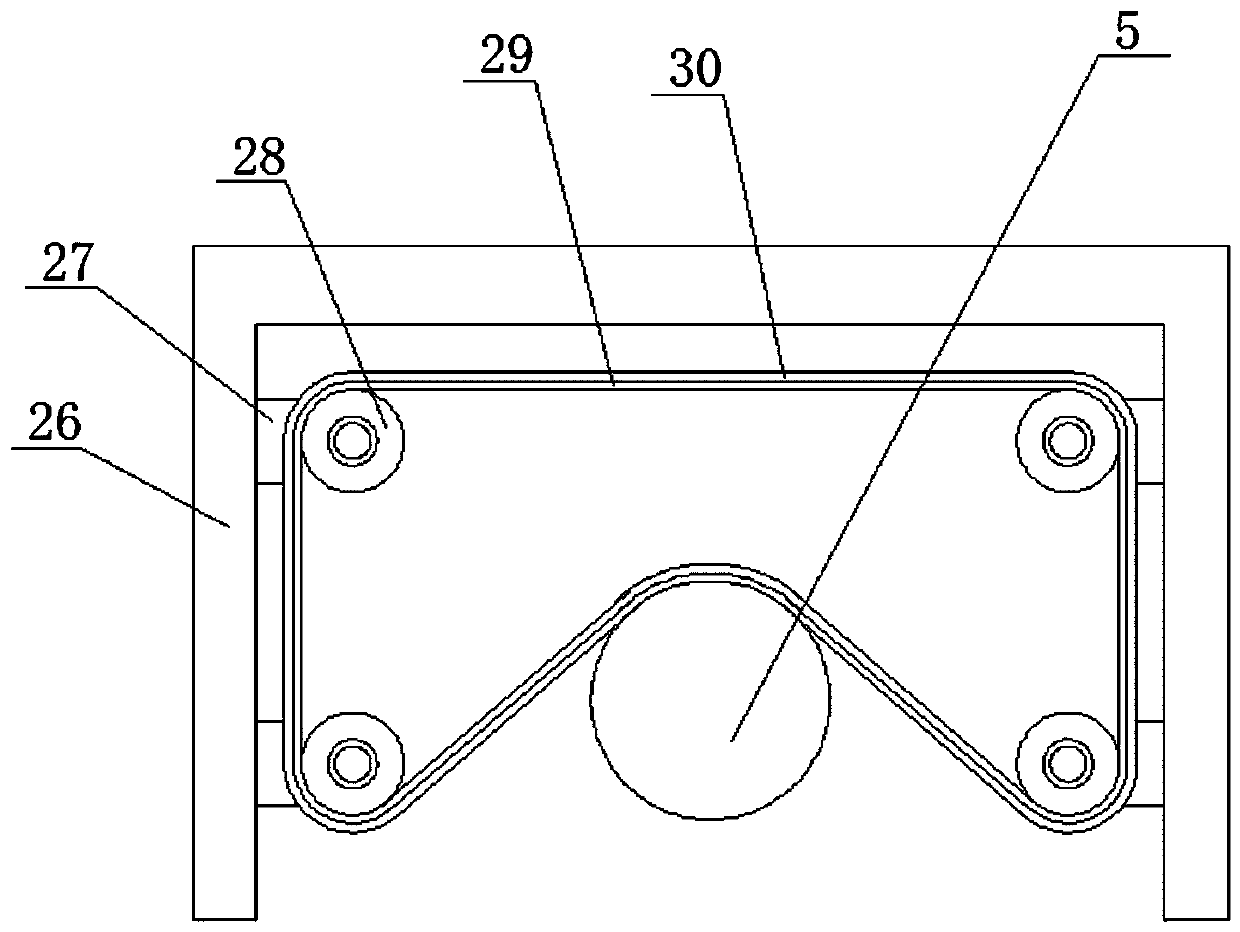

[0029] refer to Figure 1-6 In this embodiment, an intelligent grinding and polishing machine for semiconductor materials is proposed, including a base 1, a controller is fixedly installed on the base 1, two columns 2 are fixedly installed on the top of the base 1, and the two columns 2 are close to each other One end is rotatably connected with a card cover 3, the same semiconductor rod 5 is clamped on the two card covers 3, the same beam 4 is fixedly installed on the top of the two columns 1, and a U-shaped plate 26 is slidably connected to the beam 4. Two synchronous wheels 28 are symmetrically rotated on the inner walls of both sides of the pattern plate 26, and the same synchronous belt 29 is connected to the four synchronous wheels 28, and a polishing belt 30 is fixedly installed on the synchronous belt 29. The polishing belt 30 and the The semiconductor rods 5 are in contact.

[0030] Wherein, at first the semiconductor rod 5 is clamped on the two clamping covers 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com