PVOH coating film with high peel strength and preparation method thereof

A technology of peel strength and coating film, which is applied in the field of food flexible packaging, can solve the problems of limitation, weak bonding force, printing peeling off or composite delamination, etc., and achieve the effect of reducing production cost, raw materials and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

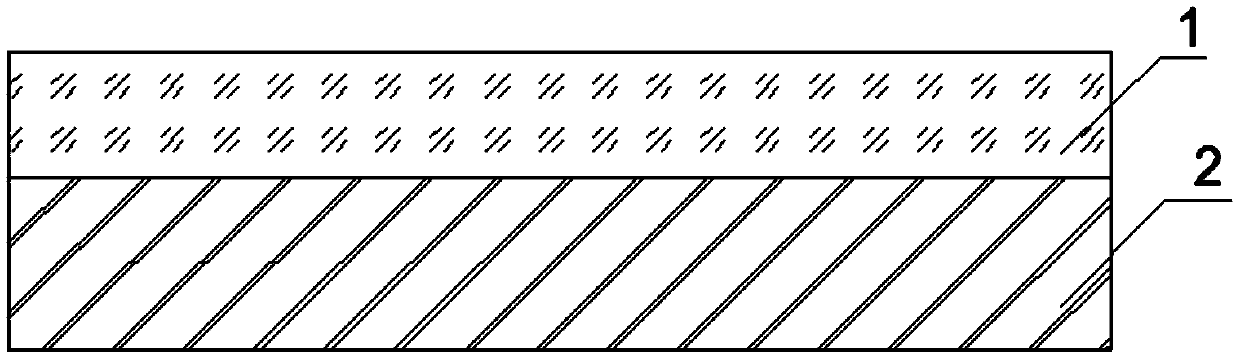

[0026] A kind of PVOH coating film with high peeling strength of the present invention, comprises substrate layer 1 and coating layer 2 of adhesion successively; Described coating layer 2 is self-adhesive PVOH coating layer 2, and described substrate layer 1 is to have Heat-sealed BOPP film layer. The self-adhesive PVOH coating layer 2 is prepared from the following raw materials by weight: 5% PVOH, 0.04% toluene diisocyanate, 0.2% amino resin, 0.005% catalyst, 0.005% surfactant, 0.003% defoamer , 94.747% deionized water.

[0027] The substrate layer 1 is a single-sided heat-sealed BOPP film; the structure and formula of the BOPP film are as follows: the structure is divided into three layers: upper, middle and lower; the upper layer is a heat-sealed layer prepared from the following raw materials by weight percentage: 95% copolymer Polypropylene and known heat seal compound and 5% synthetic silica or other inorganic silica. The middle layer is prepared from the following ra...

Embodiment 2

[0035] A kind of PVOH coating film with high peeling strength of the present invention, comprises substrate layer 1 and coating layer 2 of adhesion successively; Described coating layer 2 is self-adhesive PVOH coating layer 2, and described substrate layer 1 is to have Heat-sealed BOPP film layer. The self-adhesive PVOH paint layer 2 is prepared from the following raw materials by weight: 10% PVOH, 0.5% toluene diisocyanate, 1% amino resin, 0.02% catalyst, 0.015% surfactant, 0.015% defoamer , 88.45% deionized water.

[0036] The substrate layer 1 is a single-sided heat-sealed BOPP film; the structure and formula of the BOPP film are as follows: the structure is divided into three layers: upper, middle and lower; the upper layer is a heat-sealed layer prepared from the following raw materials by weight percentage: 99% Polypropylene and known heat seal compound and 1% synthetic silica or other inorganic silica. The middle layer is prepared from the following raw materials in w...

Embodiment 3

[0044] A kind of PVOH coating film with high peeling strength of the present invention, comprises substrate layer 1 and coating layer 2 of adhesion successively; Described coating layer 2 is self-adhesive PVOH coating layer 2, and described substrate layer 1 is to have Heat-sealed BOPP film layer. The self-adhesive PVOH coating layer 2 is prepared from the following raw materials by weight: 7% PVOH, 0.3% toluene diisocyanate, 0.6% amino resin, 0.01% catalyst, 0.01% surfactant, 0.01% defoamer , 92.07% deionized water.

[0045] The substrate layer 1 is a single-sided heat-sealed BOPP film; the structure and formula of the BOPP film are as follows: the structure is divided into three layers: upper, middle and lower; the upper layer is a heat-sealed layer, which is prepared from the following raw materials in weight percentage: 97% Copolymerized polypropylene and known heat seal compound and 3% synthetic silica or other inorganic silica. The middle layer is prepared from the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com