Low-loss optical fiber drawing system and drawing method thereof

A low-loss, optical fiber technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of different positions of structural relaxation temperature, increase of optical fiber surface relaxation time, influence of optical fiber strength, etc., to improve internal defects, reduce Fiber loss and the effect of reducing fiber loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

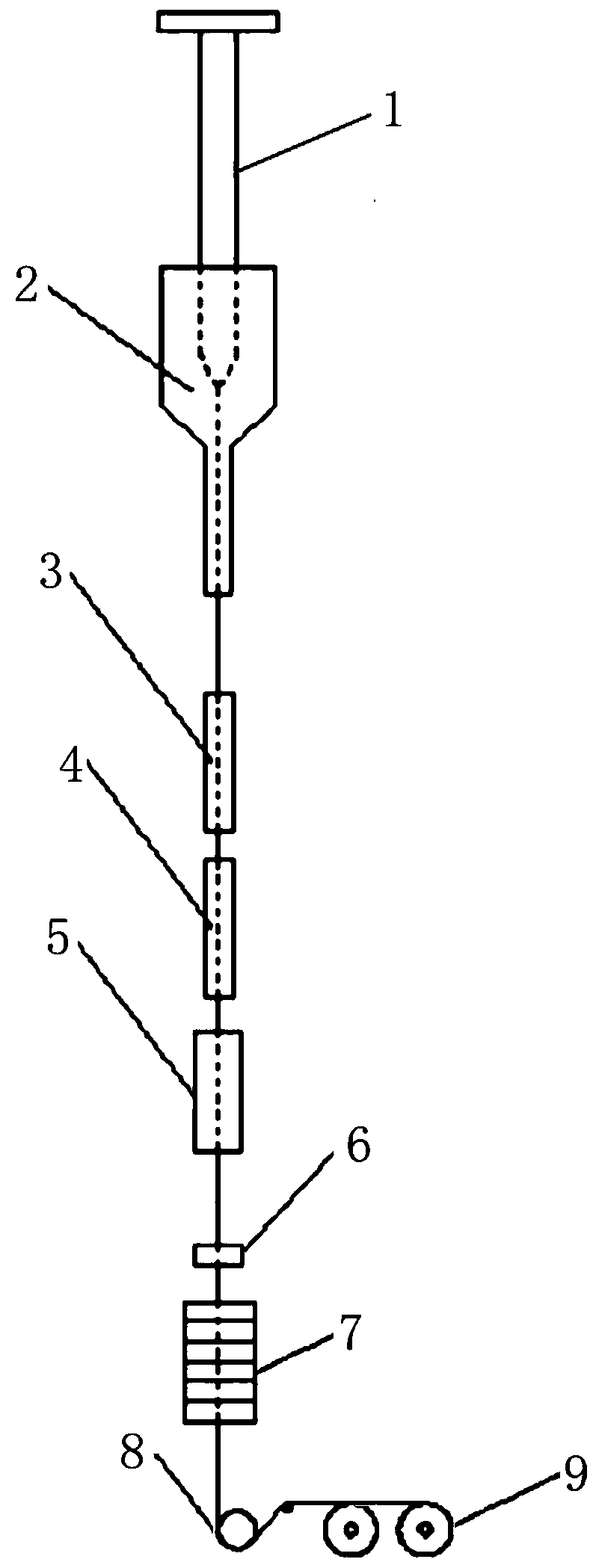

[0039] Such as figure 1 and figure 2The low-loss optical fiber drawing system shown includes a preform feeding device 1, a drawing furnace 2, a steam annealing device 3, a dehydration device 4, a cooling pipe 5, and a coater, which are sequentially arranged on the drawing tower from top to bottom. 6 and curing device 7, as well as traction device 8 and the take-up device 9 located at one side of traction device 8.

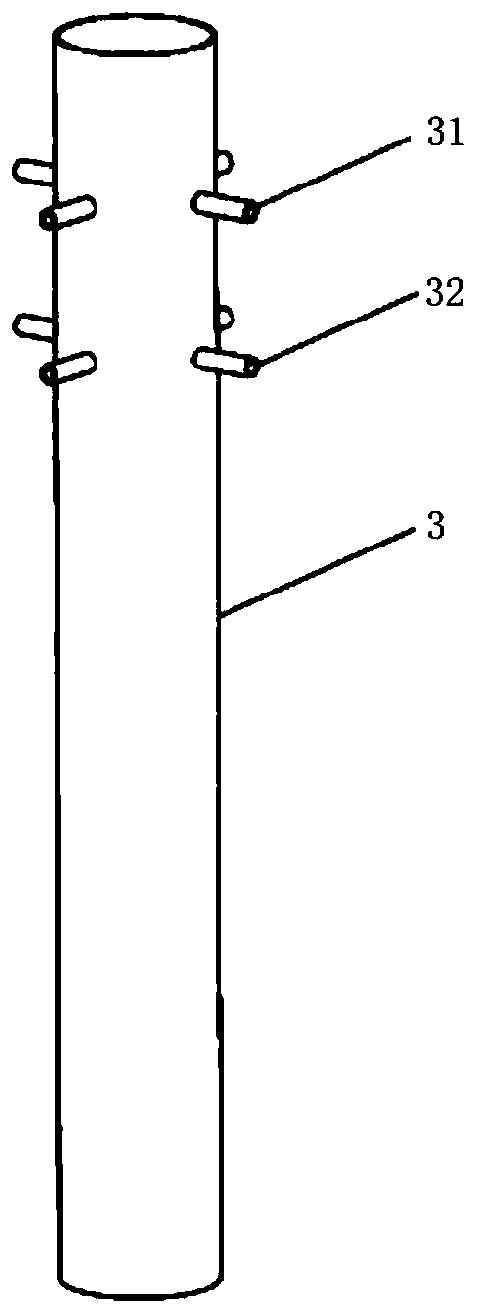

[0040] Two sets of three-degree-of-freedom mobile platforms are installed on the drawing tower. The three-degree-of-freedom mobile platforms include X-axis drive mechanisms, Y-axis drive mechanisms and Z-axis drive mechanisms. The steam annealing device 3 and the dehydration device 4 are respectively installed on two sets On the X-axis drive mechanism of the three-degree-of-freedom mobile platform, the X-axis drive mechanism is installed on the Y-axis drive mechanism, the Y-axis drive mechanism is installed on the Z-axis drive mechanism, and the Z-axis drive mech...

Embodiment 2

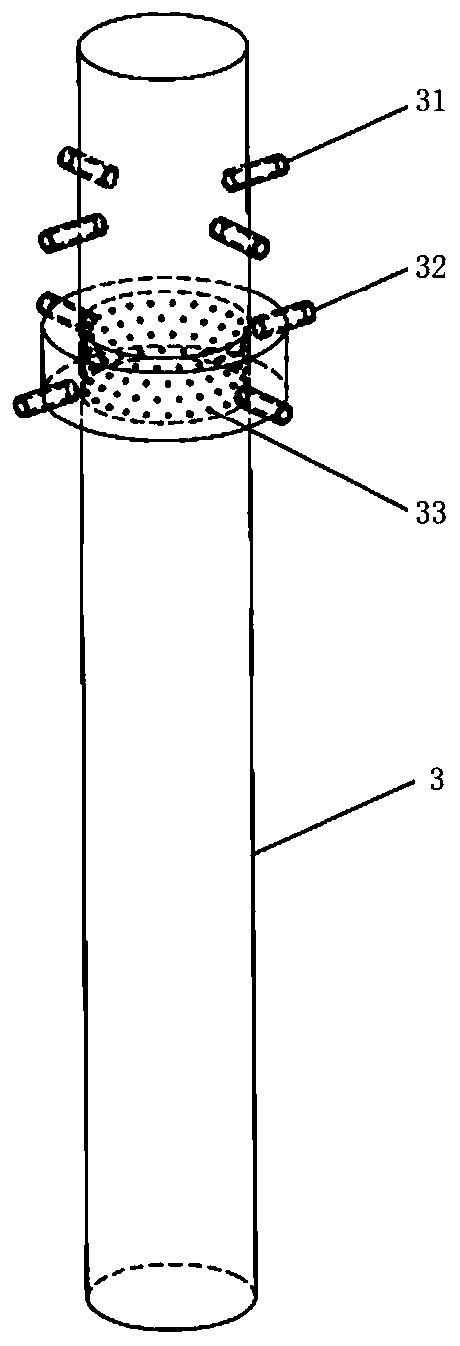

[0060] This embodiment is similar in structure to the low-loss optical fiber drawing system of Embodiment 1, except that the water vapor annealing device 3 uses microwaves to generate water vapor. In addition, as image 3 As shown, the water vapor annealing device 3 of embodiment 2 adds a double-layer cavity on the basis of embodiment 1, which is located at the outer peripheral position of the water vapor inlet 32, and the double-layer cavities are communicated through uniformly distributed small holes 33, reducing the The air pressure when the water vapor enters the cylindrical annealing device is reduced, thereby reducing the disturbance of the optical fiber in the cylindrical annealing device, thereby improving the coating quality. In order to prevent water vapor from condensing in the pipe, double-layer pipes can be used, and the outer layer is filled with circulating hot water to keep the glass tube at a certain temperature, effectively preventing water vapor from condensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com