Method for accelerating dissolution rate of soluble bridge plug

A technology of dissolution rate and soluble bridge, which is applied in earth-moving drilling, production fluids, wellbore/well components, etc., can solve the problem of difficult formation temperature intervention, and achieves increased wellbore treatment efficiency, improved production time, reduced Effects of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

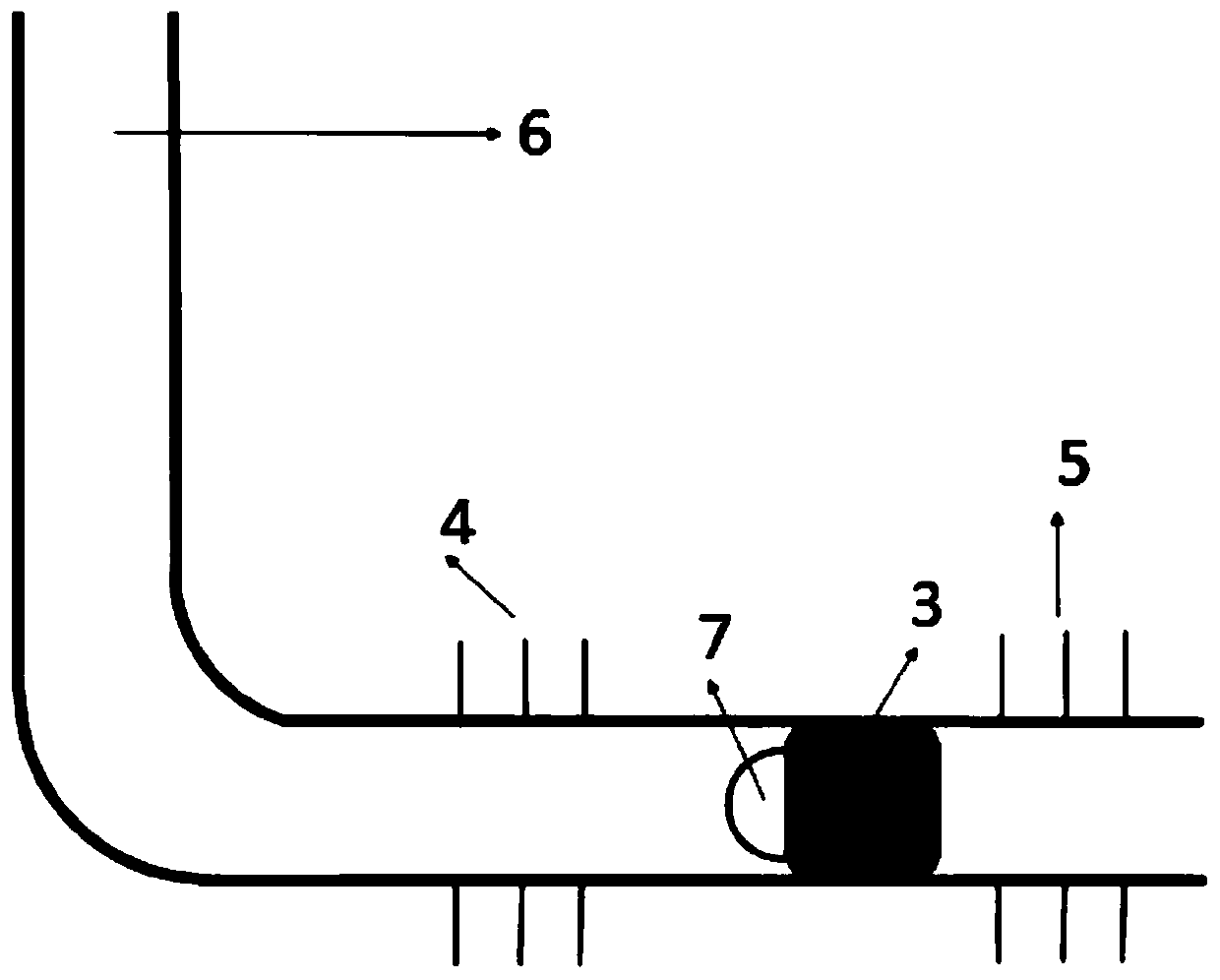

[0033] refer to figure 2 A method for accelerating the dissolution rate of a soluble bridge plug comprises the metal soluble ball described in any one of embodiments 1-3, and the method for accelerating the dissolution rate of a soluble bridge plug comprises the following steps:

[0034] Step 1: During the multi-stage fracturing operation of the horizontal well, the 5th stage of the lower perforation is not blown out after the fracturing, and the cable is connected to the perforating gun, the soluble bridge plug delivery tool and the soluble bridge plug for pumping, ignition, and delivery. Simultaneously carry out 4 perforations in the upper section. After the dissolvable bridge plug and the continuous perforation operation are successfully completed, the metal soluble ball 7 is placed on the soluble bridge plug 5 in the wellbore 6 to perform fracturing operations;

[0035] Step 2: On the basis of Step 1, pull out the cable and dissolvable bridge plug delivery tools, and carr...

Embodiment 2

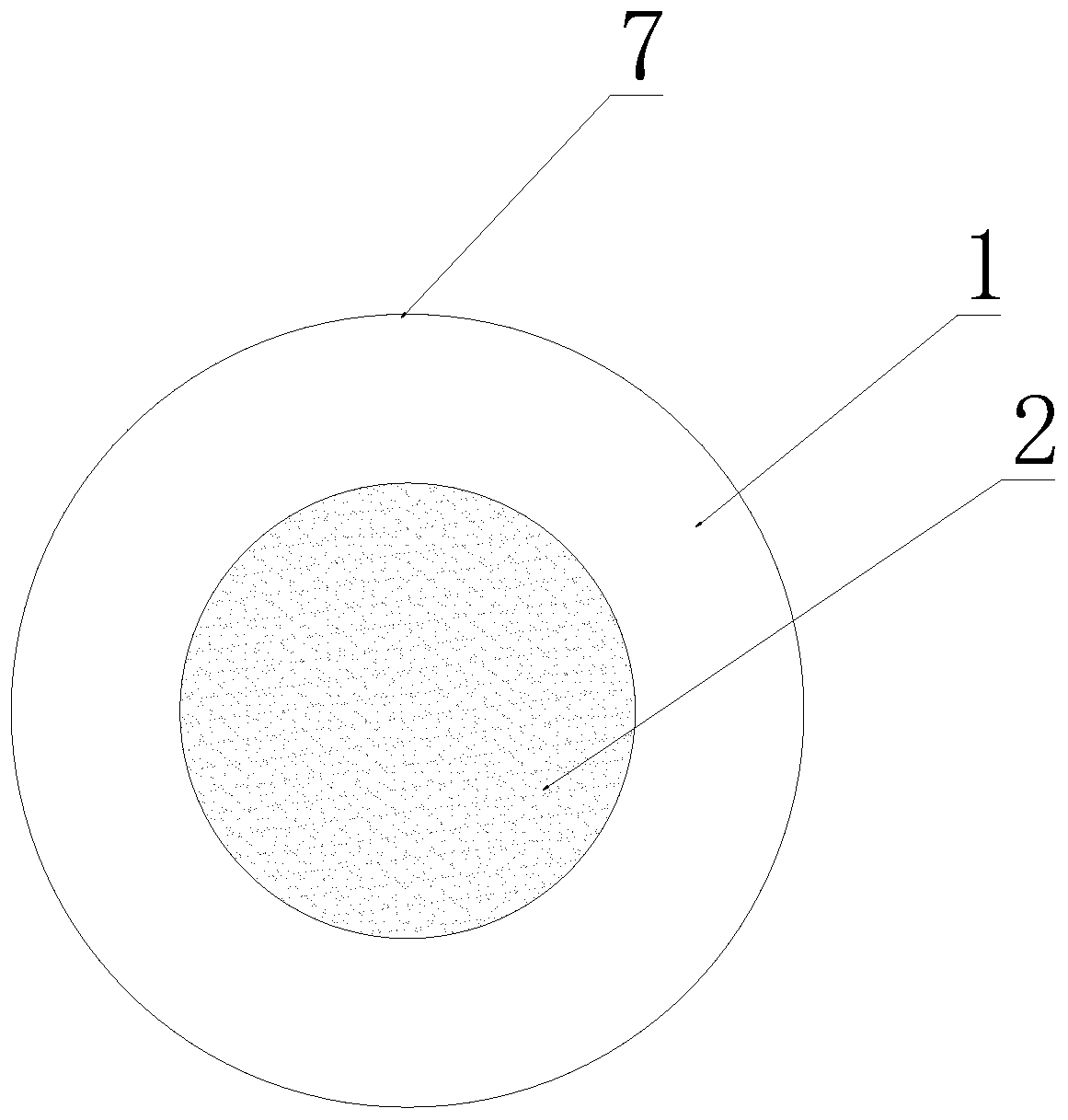

[0047] refer to figure 1 , is a schematic structural diagram of Example 2 of the present invention, a metal soluble ball, the metal soluble ball 7 includes a soluble metal 1 and a filler 2, the filler 2 is a filler sphere, and the filler sphere wraps the soluble metal 1 Form a solid sphere with two layers.

[0048] In actual use: the metal soluble ball has a double-layer structure, including soluble metal 1 and filler 2, the filler 2 is a filler sphere, and the filler sphere is wrapped with soluble metal 1 to form a double-layer solid sphere, and the soluble ball dissolves Finally, the filler will speed up the dissolution of the soluble bridge plug 3, and greatly accelerate the dissolution rate of the soluble bridge plug 3, thereby reducing the soaking time and increasing the well production rate.

Embodiment 3

[0050] Compared with Embodiment 1, the difference of this embodiment is that: the radius of the filler 2 sphere is smaller than the radius of the metal soluble sphere 7 .

[0051] In actual use: the radius of the filler 2 sphere is smaller than the radius of the metal soluble ball 7, which ensures the construction time in the early stage of the construction process. When it is necessary to accelerate the dissolution of the soluble bridge plug 3, the filler 2 releases the dissolution factor to accelerate the dissolution. Dissolving, thereby improving the dissolution rate of the soluble bridge plug 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com