A Deformation Control Method of Tunnel Surrounding Rock Applied to Granite Alteration Zone Under Seepage Conditions

A technology of surrounding rock deformation and control method, which is applied in the direction of tunnels, earthwork drilling, mining equipment, etc., can solve the problems of overall instability of excavation surface, increase of tunnel construction cost, multiple changes of support schemes, etc., and achieve economical support cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

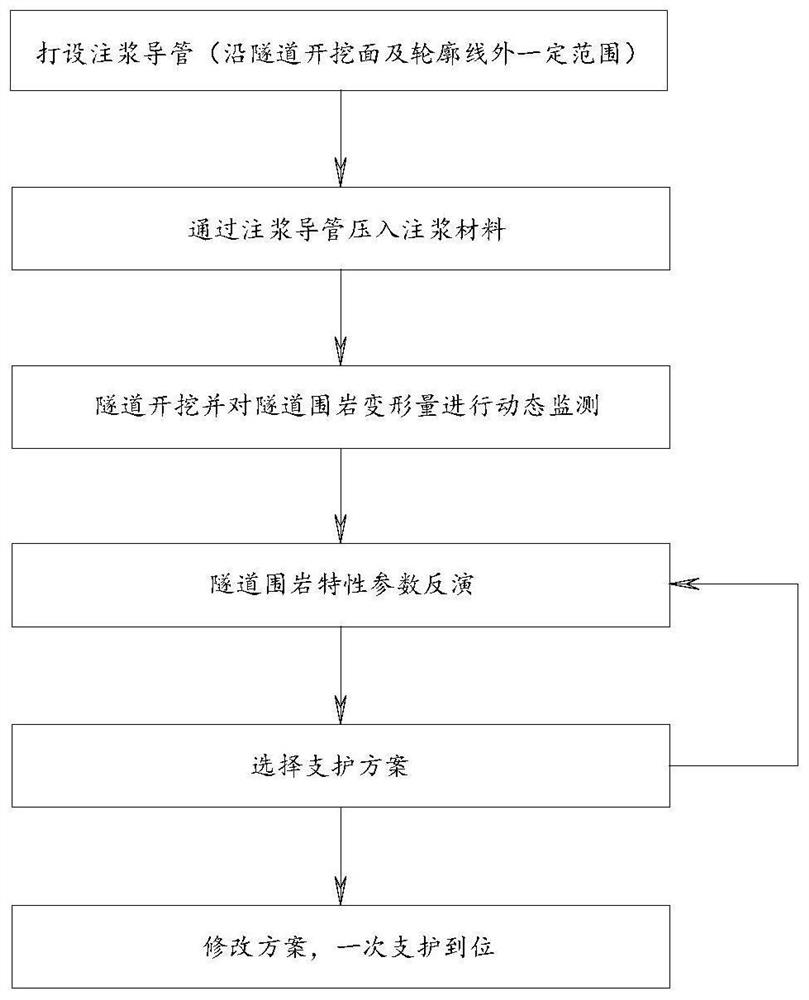

Method used

Image

Examples

Embodiment

[0032] Qingshui Tunnel is located in the Anping-Nuodong section from Hongtang to Cenxi section of the Luo (Yang) Zhan (Jiang) Railway. The entrance mileage is DK439+346, the exit mileage is DK442+782, and the total length is 3436m. It is the control project of the Yongcen section of the Luozhan Railway. one.

[0033] The strata of the underlying bedrock of the tunnel are mixed in sequence, and the underlying bedrock is late Yanshanian granite and middle Ordovician Suoweiling Group sandstone interbedded with shale, limestone and marble formed by hydrothermal alteration. Among them, the granite is strongly weathered and varied, the rock mass is broken, the fully weathered layer is 35-80m thick, the rock core is soil columnar, silt-like, and spherical weathered bodies can be seen locally, which belongs to the granite alteration zone mentioned in this patent.

[0034] Section DK442+633~+782 crosses a long flowing gully and is located in the low and gentle area at the foot of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com