Convenient and fast industrial furnace

An industrial furnace and convenient technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of high temperature outside the furnace body, unfavorable energy saving, large heat loss, etc., to improve thermal efficiency and reduce heat loss. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

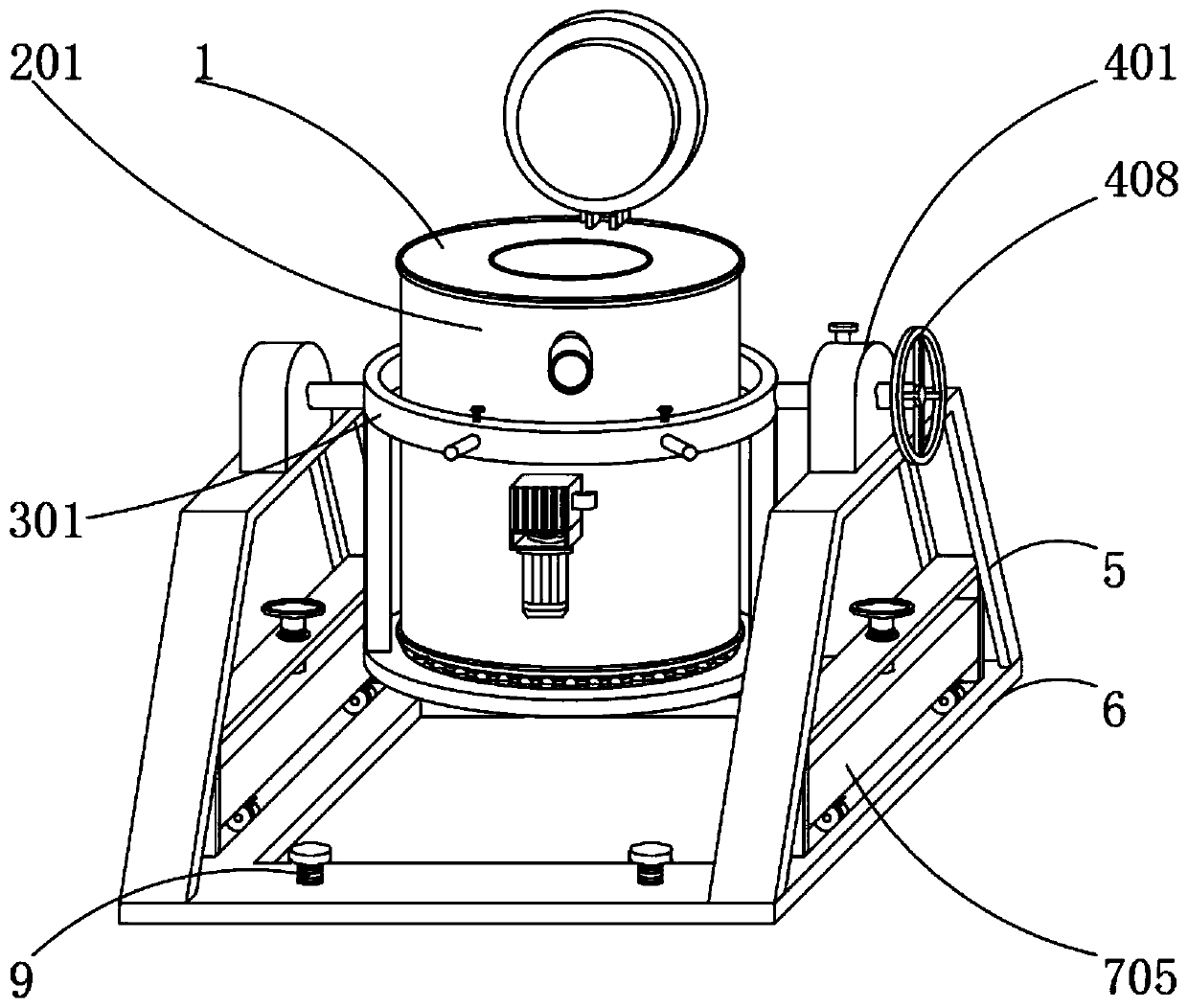

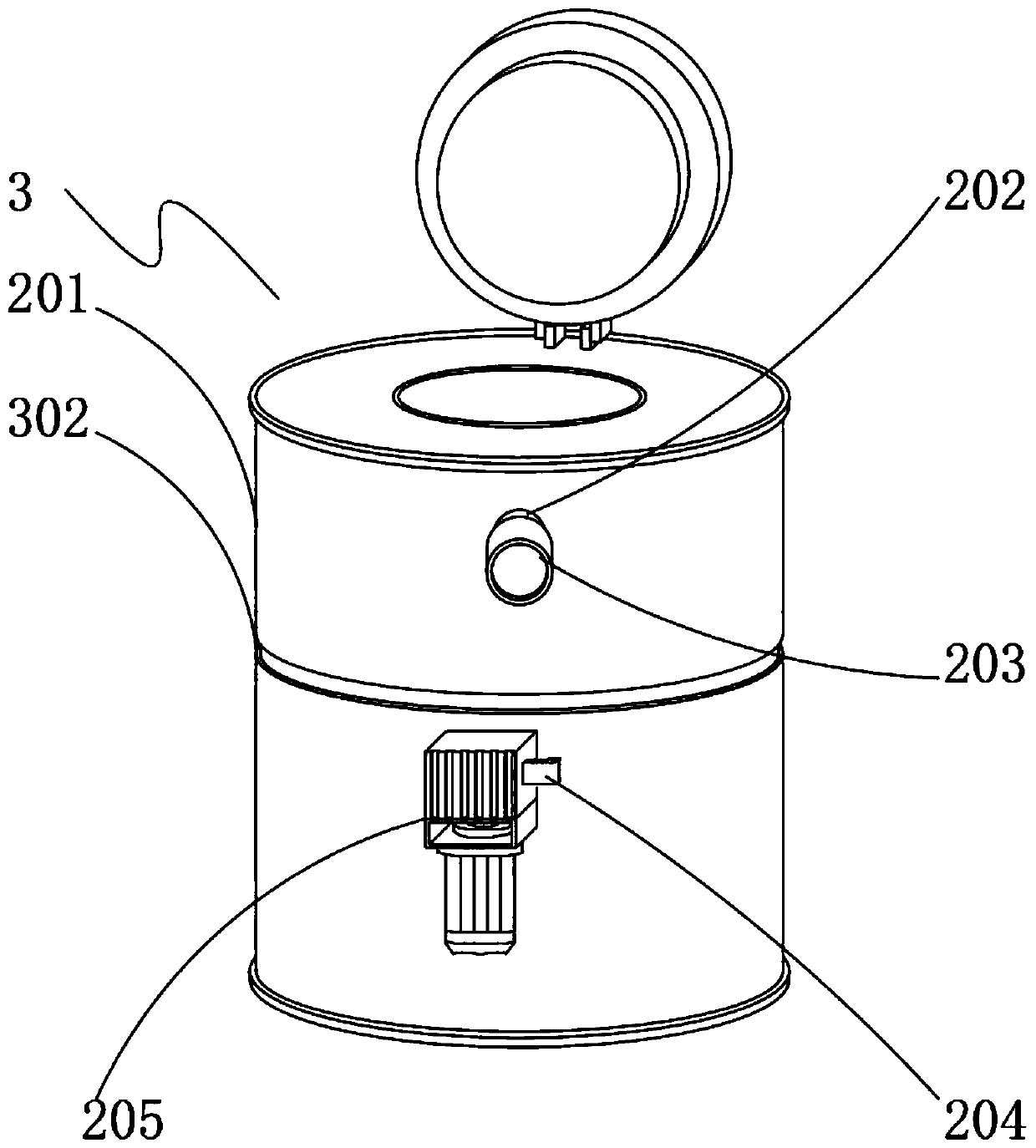

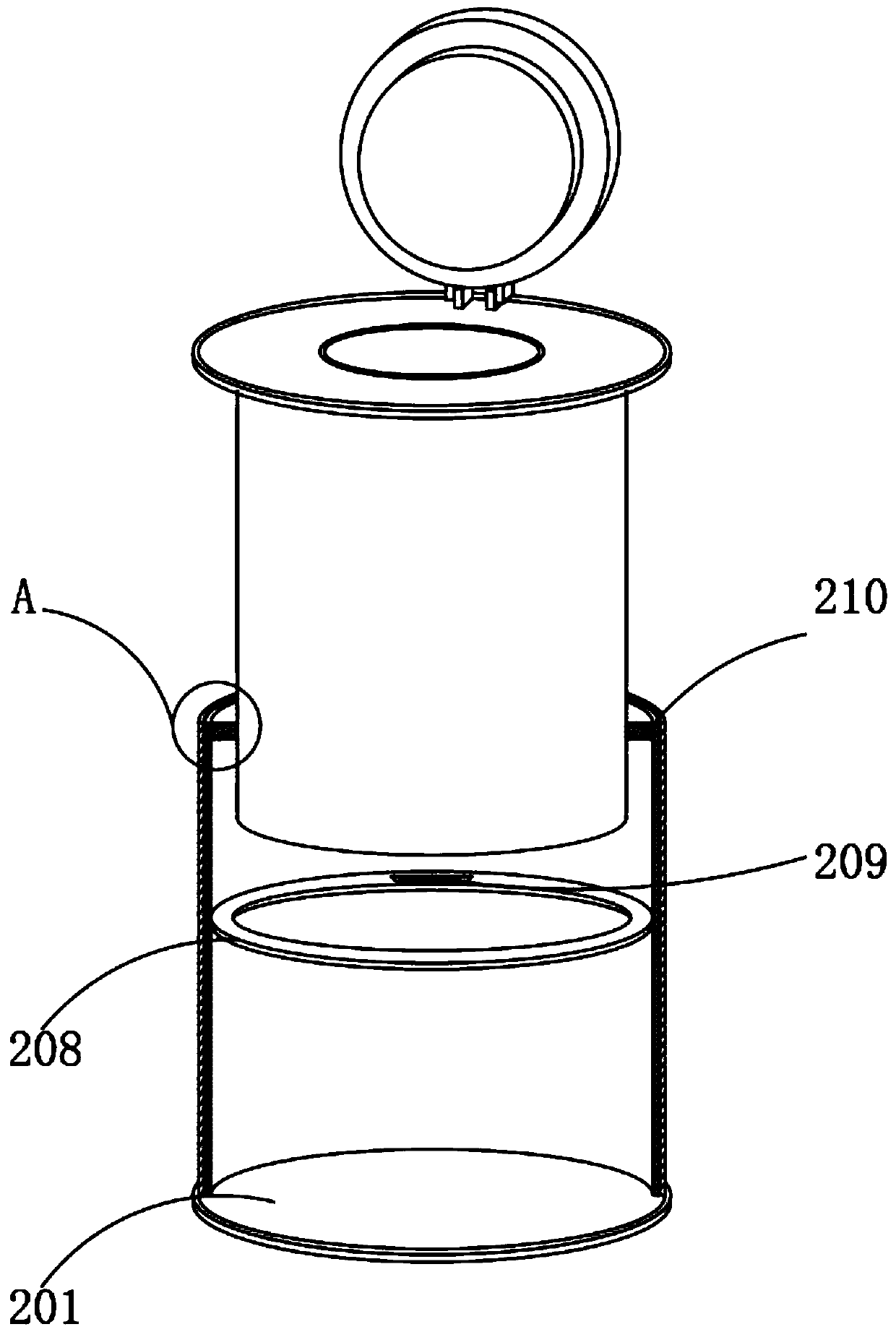

[0044] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a portable industrial furnace, including a furnace body 1, a heat preservation component 2 is arranged on the outside of the furnace body 1, and the heat preservation component 2 includes an outer cylinder 201, an air inlet pipe 202, an end cover 203, a pump Air pipe 204, vacuum pump 205, glass cylinder 206, silver-plated film 207, separation ring 208, communication port 209 and sealing ring 210;

[0045] The outer cylinder 201 is fixedly socketed on the outer side of the furnace body 1, and an air intake pipe 202 is installed through the upper front of the outer cylinder 201. One end of the air intake pipe 202 is threaded with an end cover 203, and an exhaust pipe 204 is installed through the lower front of the outer cylinder 201. One end of the exhaust pipe 204 is connected with a vacuum pump 205, and a glass cylinder 206 is placed inside the outer cylinder 201. The air inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com