Method and device for measuring thickness of material sample

A thickness value, measuring host technology, applied in the field of sensor, mechanical test technology and mechanical measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

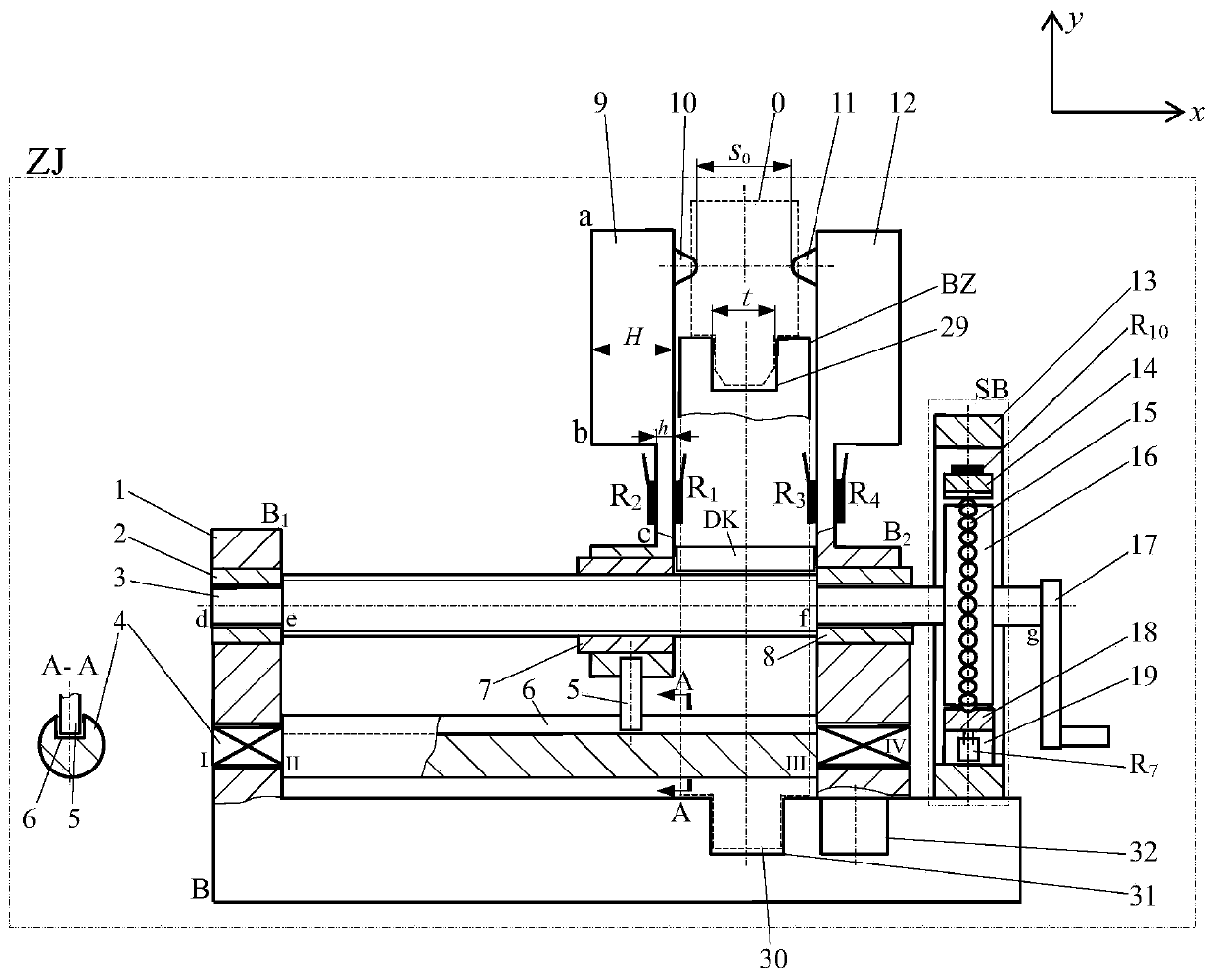

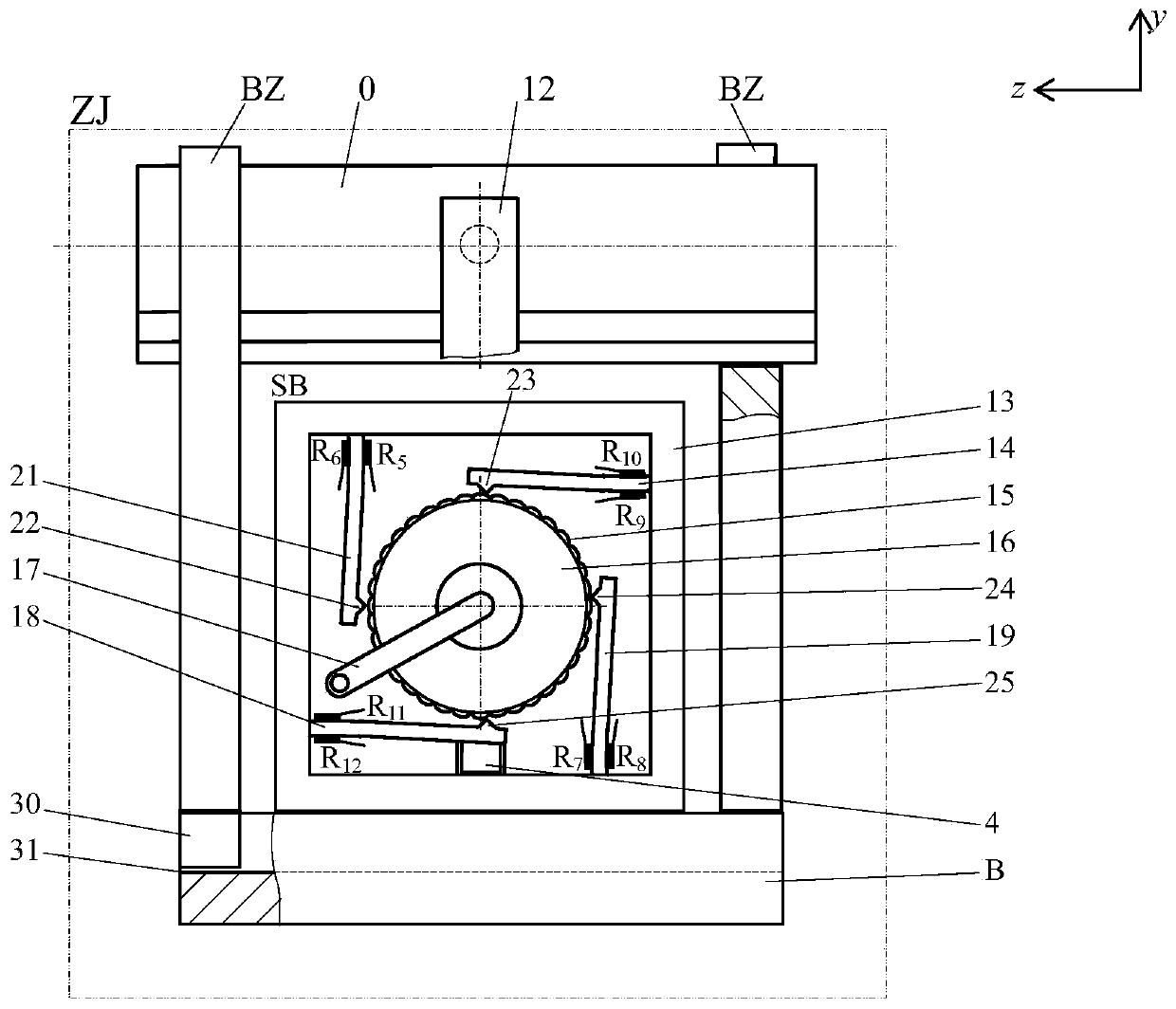

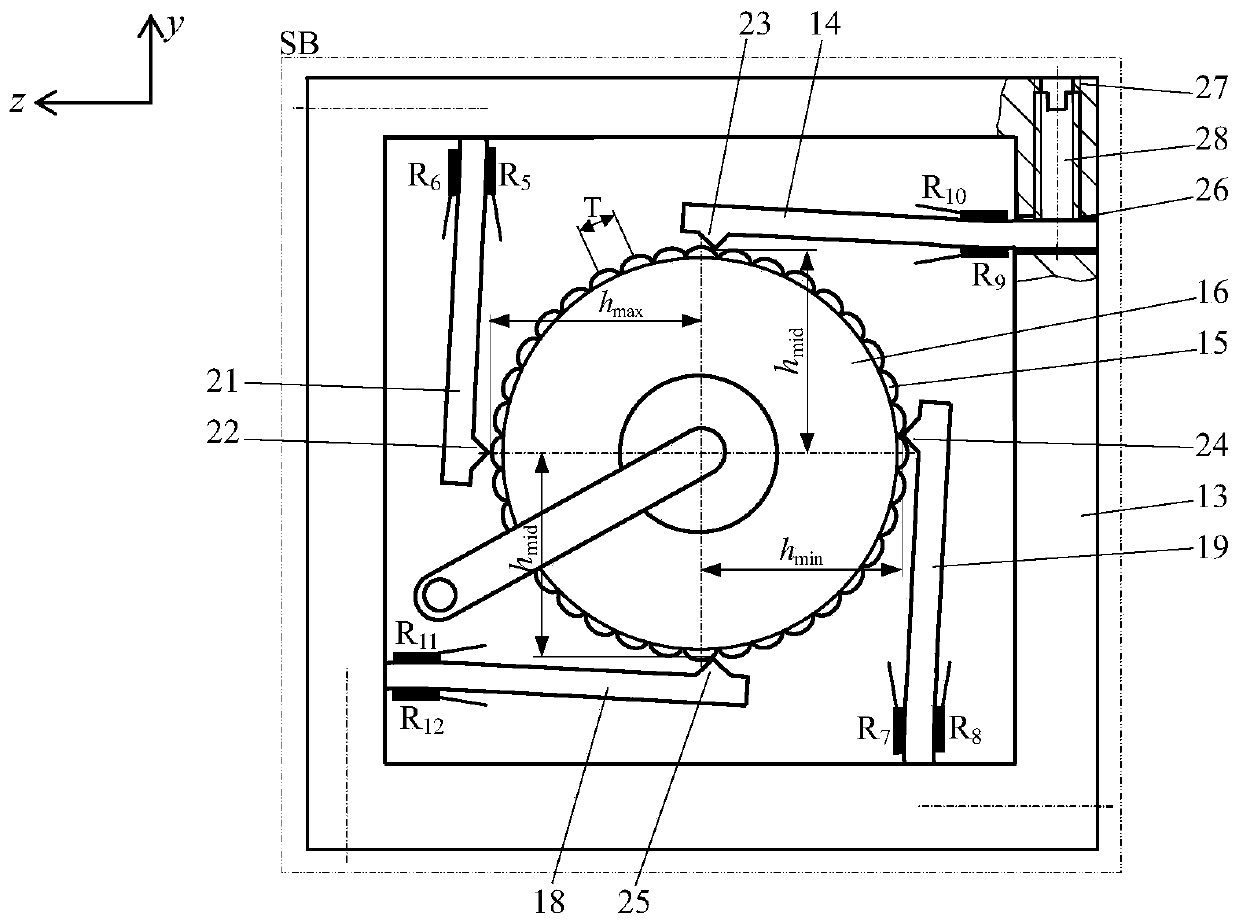

[0067] Below in conjunction with accompanying drawing this design is described further.

[0068] refer to Figure 1-Figure 7 , this design is a method and device for measuring the thickness of a material sample, including a measuring host ZJ, a standard device 0, a positioning block DK, a test piece SJ, a standard device support BZ, a test piece support SZ and a data acquisition-analysis-processing unit 7 part. The measuring host ZJ is the basic measuring device, and the remaining six parts cooperate with the measuring host to form a measuring system.

[0069] The measuring host ZJ is composed of frame 1, coding screw, limit guide rod 4 and double cantilever beam sensors. The structure of the frame 1 includes a base plate B, a left bearing support plate B fixed on the upper part of the base plate B 1 and right bearing support plate B 2 . The upper part of the bottom plate B is processed with a first positioning groove 31 and a second positioning groove 32, and the left be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com