Gear rack feeding mechanism

A feeding mechanism, rack and pinion technology, applied in the direction of conveyor objects, metal processing equipment, feeding devices, etc., can solve the problems of high cost and single stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

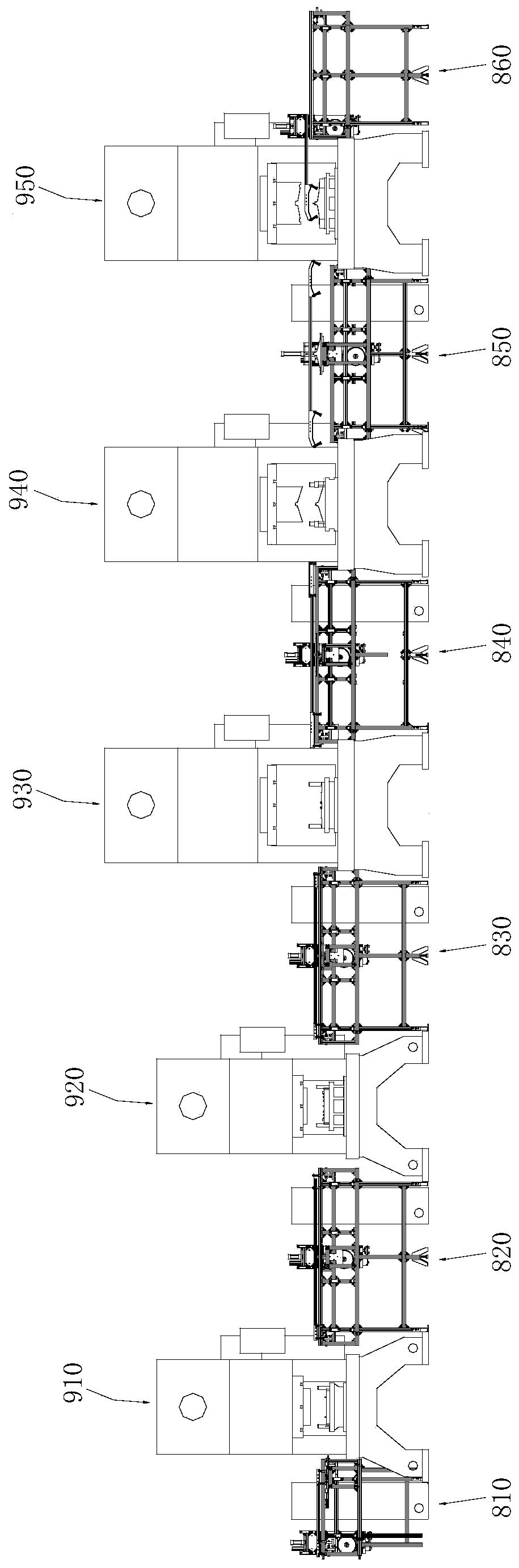

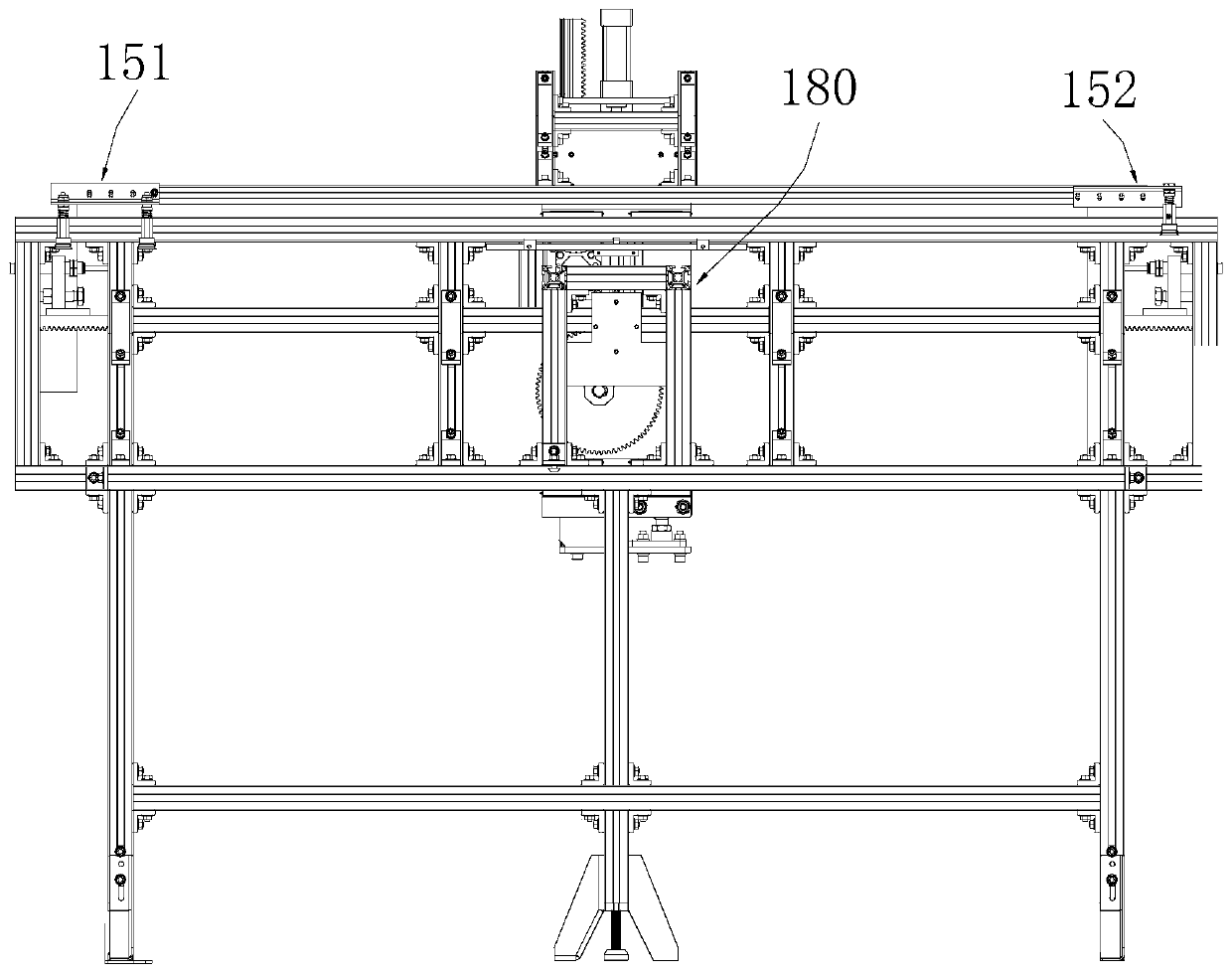

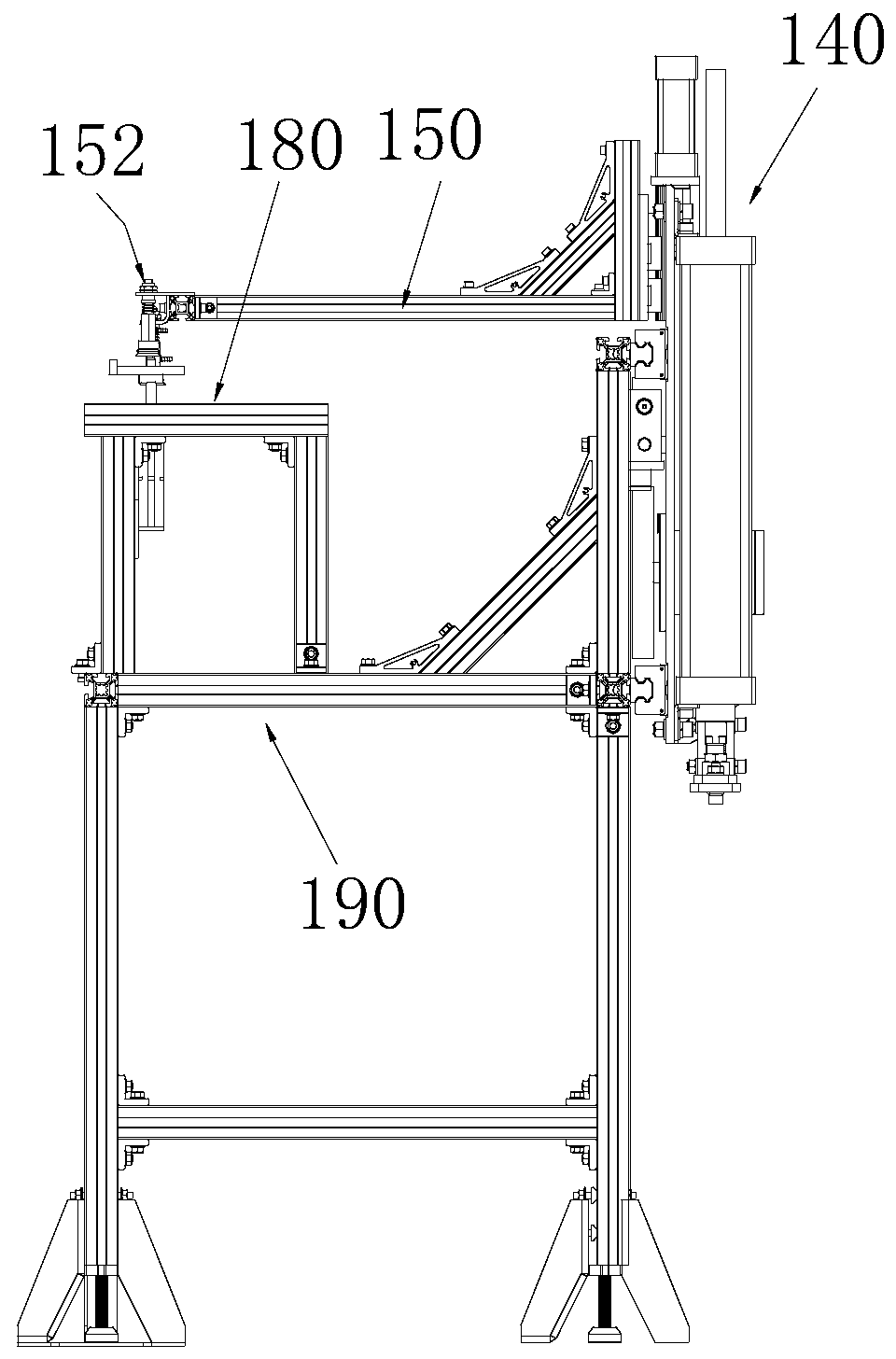

[0044] In this embodiment, a punch production line is provided, such as Figure 1 to Figure 4 As shown, it includes five punches from the first punch 910 to the fifth punch 950, and the first feeding mechanism 810 to the sixth feeding mechanism 860 are arranged at each two punches and the two ends of the entire punch production line, and each feeding mechanism applies The above-mentioned rack and pinion feeding mechanism 100 is used as a power mechanism. Rack and pinion feeding mechanism 100 comprises frame 190, sliding plate 140, driving rack 110, driven rack 120, duplex gear 130 and grabbing arm 150, and frame 190 is fixedly installed on the ground, and frame 190 is made of A frame structure made of aluminum profiles or other common profiles. The upper part of the frame 190 is made of a plurality of profiles into a rectangular frame. Slide rails are arranged on the two long sides of the rectangular frame. The sliding plate 140 can be moved through two sliders. Slidingly mou...

Embodiment 2

[0050] In this embodiment, due to the different processing procedures of the first punch to the fifth punch 950, the models and sizes of the first punch to the fifth punch 950 are different, resulting in different installation heights during workpiece processing, so the first feeding mechanism 810 to the fifth The height of the frame 190 of the rack and pinion feeding mechanism 100 among the six feeding mechanisms 860 is also adjusted accordingly. At the same time, in order to meet the workpiece handling between punching machines of different heights, compared with the first embodiment, no additional mechanism is added, but the profiles originally arranged horizontally in the frame 190 are changed to inclined ones, and the rest of the structure remains unchanged. When the second to the fifth feeding mechanism 850 for realizing workpiece transfer between punches of different heights are working, the second feeding mechanism 820 is used as an example, the height difference betwee...

Embodiment 3

[0053] For the punches of different heights in the second embodiment, in order to meet the workpiece handling between punches of different heights, the first handling assembly 151 and the second handling assembly 152 on the same grabbing arm 150 can be set to different heights, and the driven teeth Bar 120 is still set horizontally. The first handling assembly 151 is lower than the second handling assembly 15210cm in the horizontal direction, and this height difference can be realized by adding a connecting piece 210 between the first handling assembly 151 and the grabbing arm 150, as in the first handling assembly 151 A connection block with a thickness of 10cm is set between the grab arm 150, and the second handling assembly 152 is directly connected to the grab arm 150 to realize a height difference between the two; the left and right parts of the grab arm 150 can also be set as At different heights, the left and right parts are in a zigzag structure, forming a height diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com