Automobile hub spinning production line

A technology for automobile hubs and production lines, applied in the direction of rims, vehicle parts, molding tools, etc., can solve the problems of insufficient production efficiency, large space occupation, unfavorable monitoring operation, etc., to reduce the transportation distance, improve efficiency, and smooth and orderly transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

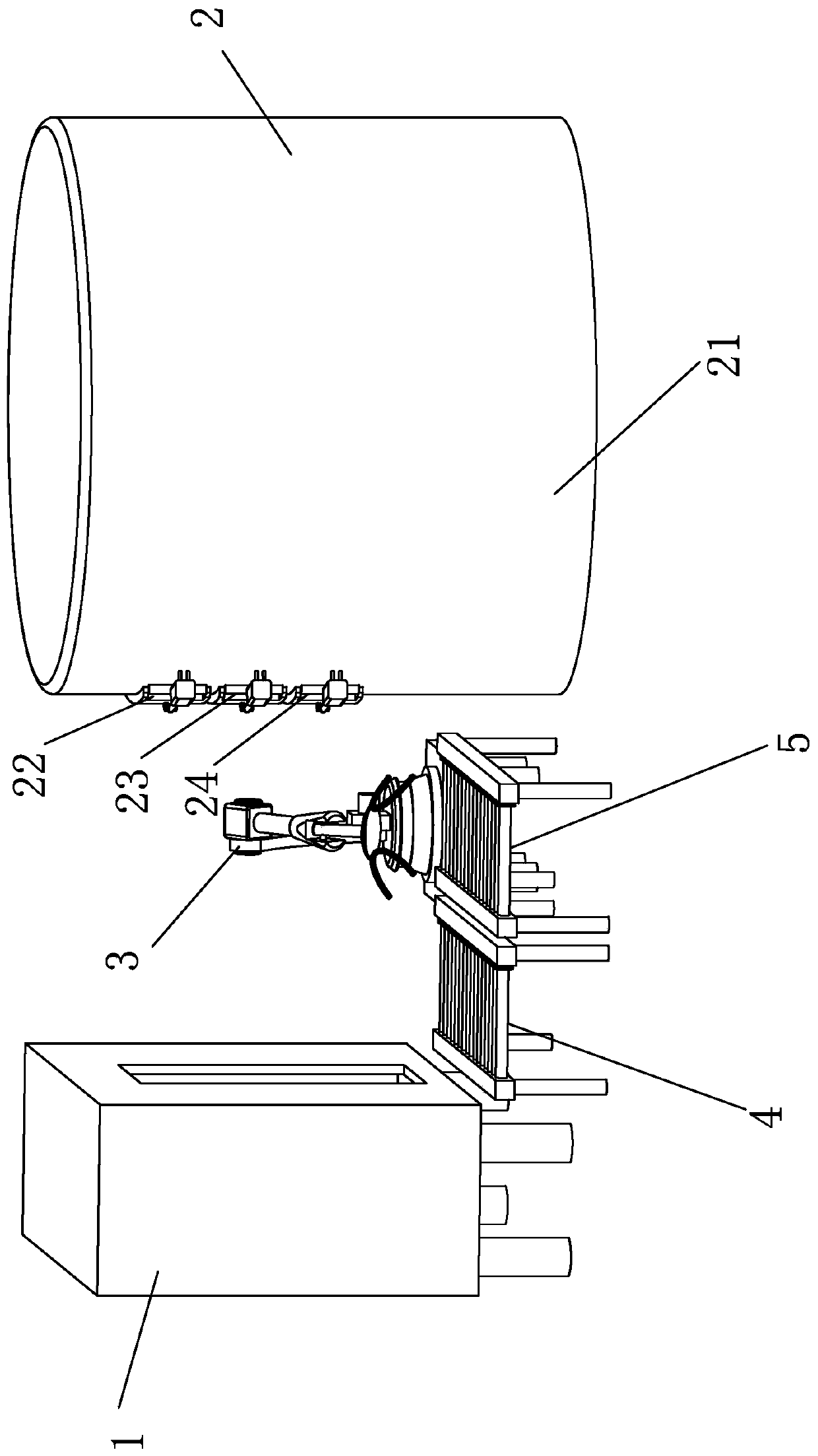

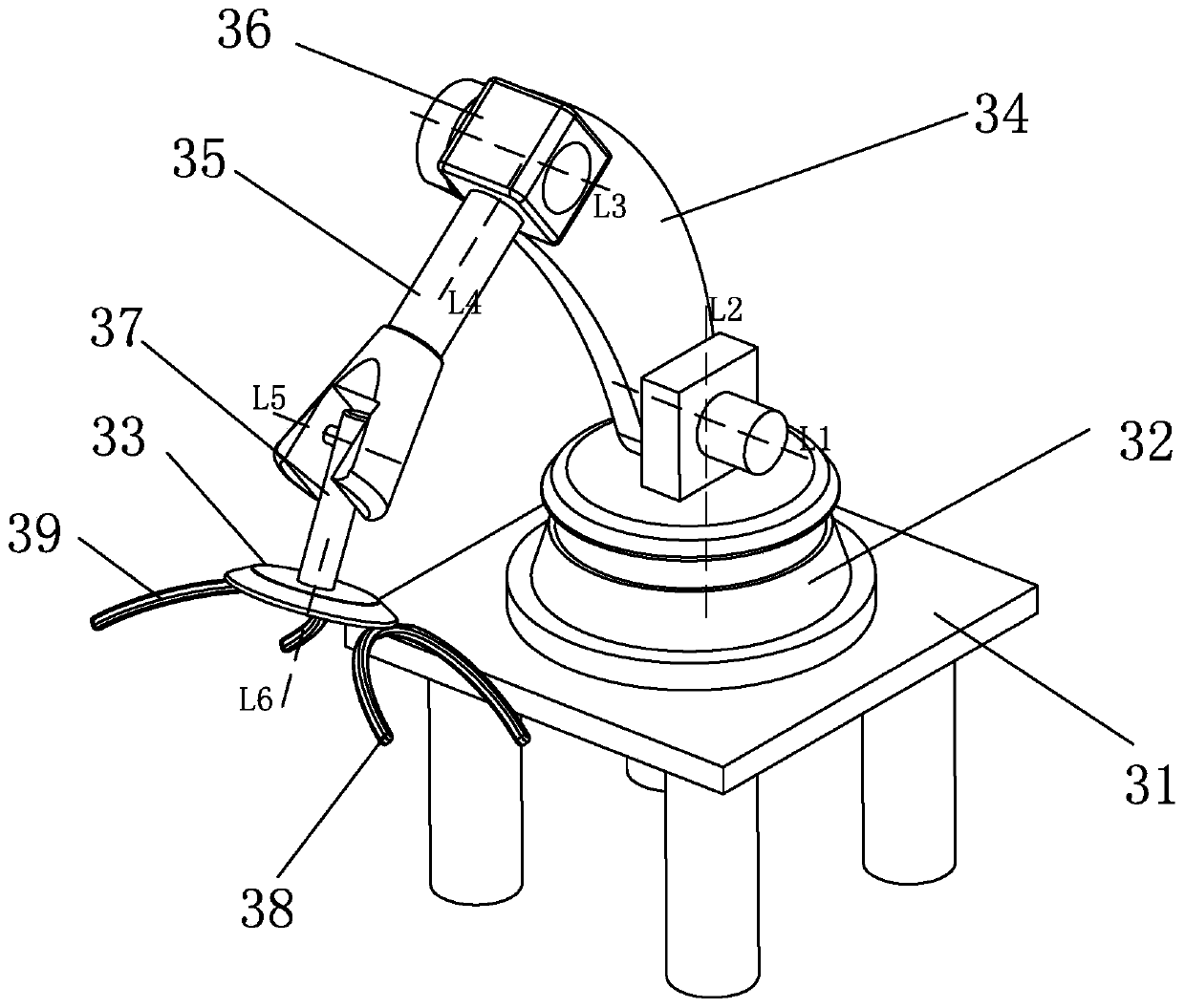

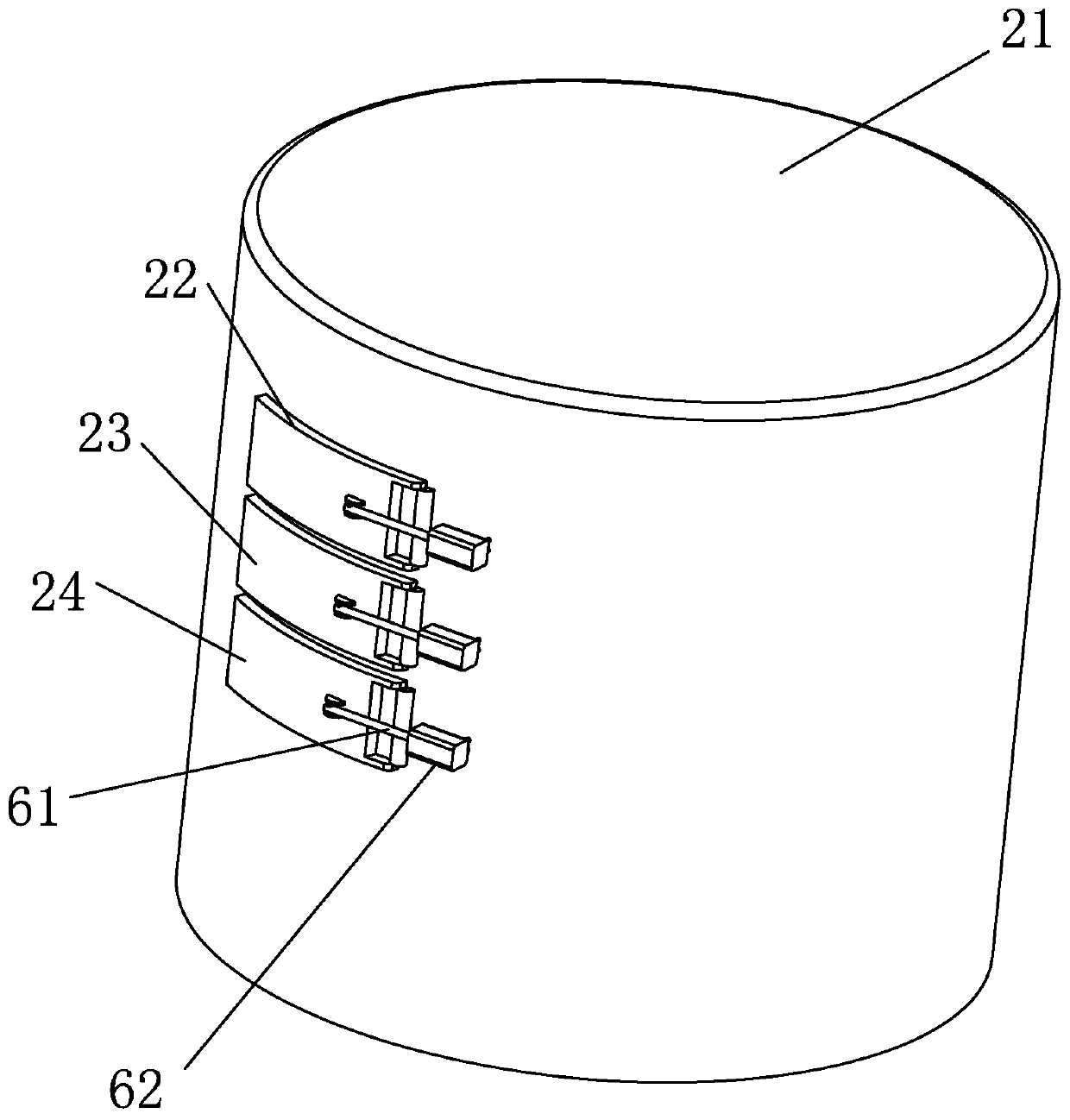

[0025] Such as Figure 1-3 As shown, an automobile hub spinning production line includes a spinning machine 1, a preheating furnace 2, a manipulator assembly between the spinning machine 1 and the preheating furnace 2, a first conveyor belt 4 and a second conveyor belt Belt 5, the conveyor belt includes a motor, a transmission sprocket and several rotating rollers, and the transmission sprocket drives several transmission rollers to rotate synchronously, thereby realizing conveying. The preheating furnace 2 includes a body of furnace 21 and an annular conveying track placed in the body of furnace 21. The annular conveying track can refer to prior art such as belts. The body of furnace 21 is provided with a furnace door, and the manipulator assembly It includes a linked first manipulator 38 and a first manipula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com