A kind of sand core and its preparation method and casting mold

A sand core and bone core technology, which is applied in the field of foundry sand cores, can solve problems such as self-weight, large sand core contours, and sand core cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] As one of the aspects of the present invention, the present invention proposes a method for preparing a sand core, comprising:

[0024] 1) prepare core bone according to the structure of sand core;

[0025] 2) forming an intermediate material layer on at least part of the outer surface of the mandrel;

[0026] 3) Place the mandrel in the sand core mold, use refractory fillers to fill sand and mold to obtain the original sand core, and dry the original sand core;

[0027] 4) Roasting the dried sand core blank to obtain a sand core; wherein the roasting temperature in the roasting process is higher than the action point temperature of the intermediate material.

[0028] In this application, the core bone is used in the sand core, which can effectively increase the strength and rigidity of the sand core, prevent the deformation of the sand core, and improve the dimensional accuracy of the sand core. Since the expansion coefficient of the core bone is much higher than tha...

Embodiment 1

[0041] A method for preparing a sand core for titanium alloy casting, comprising:

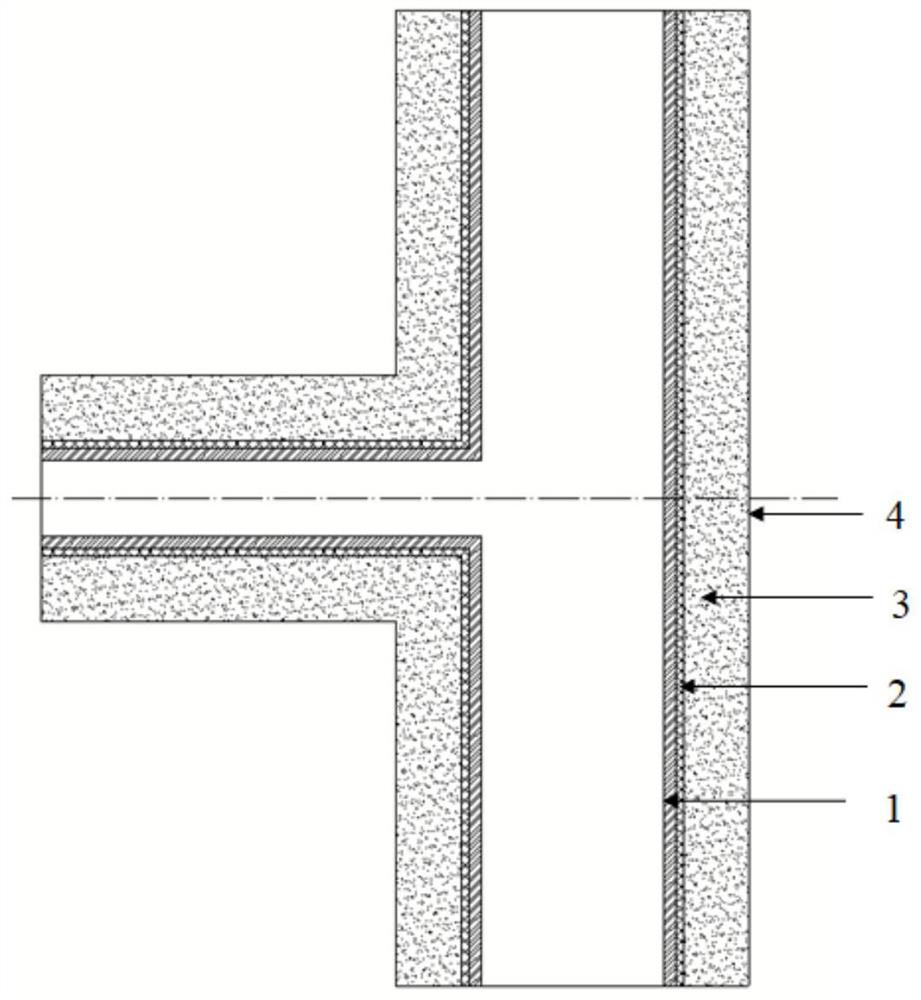

[0042] 1) Prepare according to the structure of the sand core such as figure 1 The core bone 1 is shown, and the core bone 1 has a shape roughly conforming to the shape of the sand core; the core bone 1 is a hollow cast iron core bone, and the wall thickness of the core bone 1 is 2mm.

[0043] 2) A layer of paraffin wax layer 2 is evenly coated on the outer surface of the prepared mandrel 1, the melting temperature of the used paraffin wax is about 50° C., and the thickness of the paraffin wax layer 2 is 0.5 mm.

[0044] 3) Put the mandrel 1 in the sand core mold to ensure that the mandrel 1 is basically in the center of the mold cavity, fill the pre-mixed titanium alloy casting special refractory filler into the sand core mold cavity, and carry out sand filling molding Get the sand core blank and dry it naturally. The sand core blank is formed with a refractory filler layer 3 on the outer su...

Embodiment 2

[0048] A method for preparing a sand core for titanium alloy casting, comprising:

[0049] 1) Prepare the required bone core according to the structure of the sand core. The core bone has a roughly conformal shape to the sand core; the core bone is a hollow cast iron core bone, and the wall thickness of the core bone is 5mm.

[0050] 2) A layer of paraffin wax layer is evenly coated on the outer surface of the prepared mandrel, the melting temperature of the used paraffin wax is about 50° C., and the thickness of the paraffin wax layer is 0.5 mm.

[0051] 3) Place the mandrel in the sand core mold to ensure that the mandrel is basically in the center of the mold cavity, fill the special refractory filler for titanium alloy casting that has been mixed in advance into the sand core mold cavity, and perform sand filling molding to obtain sand Core blank, and dry naturally. The sand core blank is formed with a refractory filler layer on the outer surface of the core bone, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com