Method of casting thin wall water chamber for high power diesel engine

A high-power diesel engine and cooling water jacket technology, which is applied to casting molding equipment, casting molds, and casting mold components, can solve problems such as water leakage, scrapping of cooling water jackets, and deformation of finished cooling water jackets, and achieve uniform wall thickness and size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

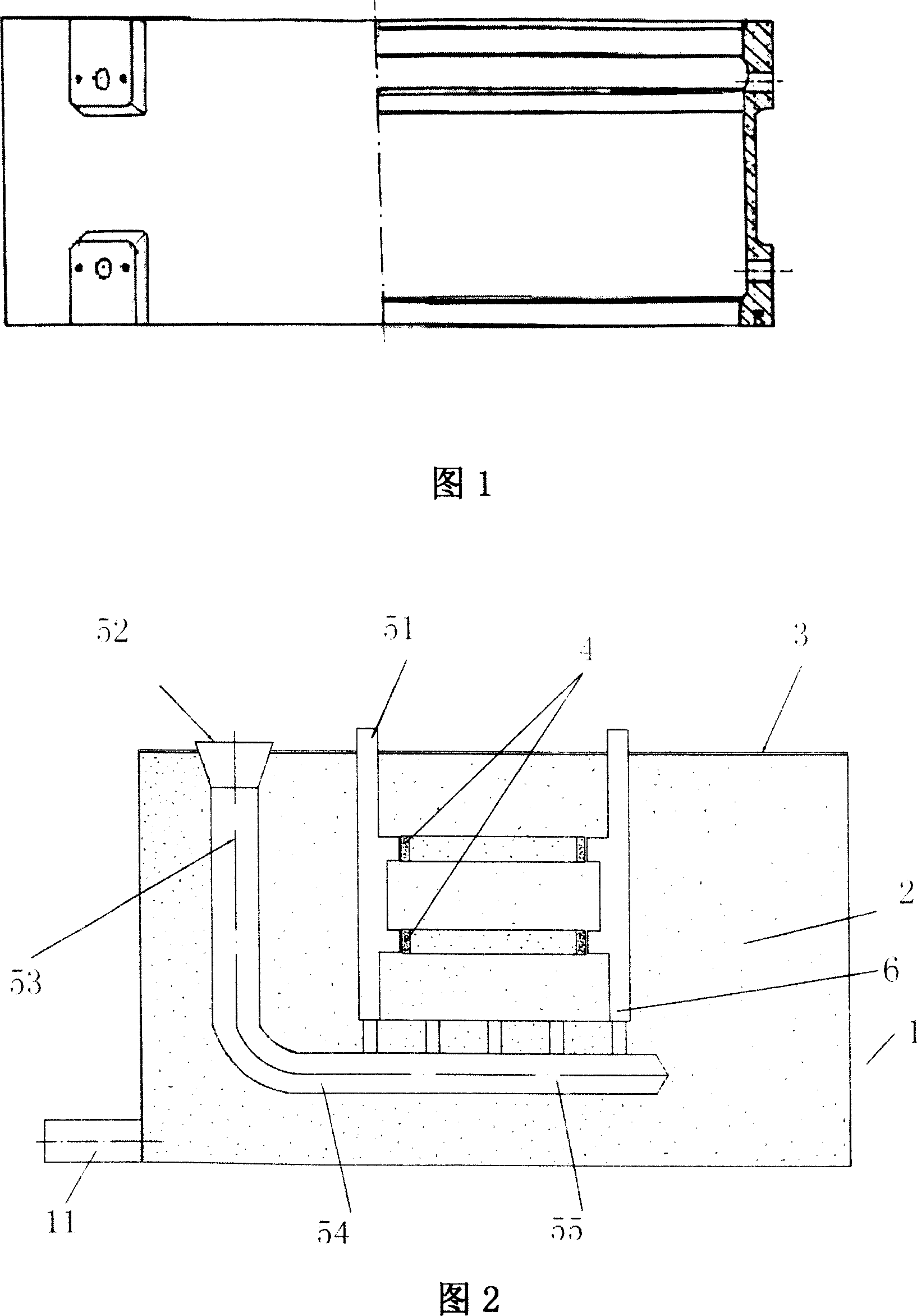

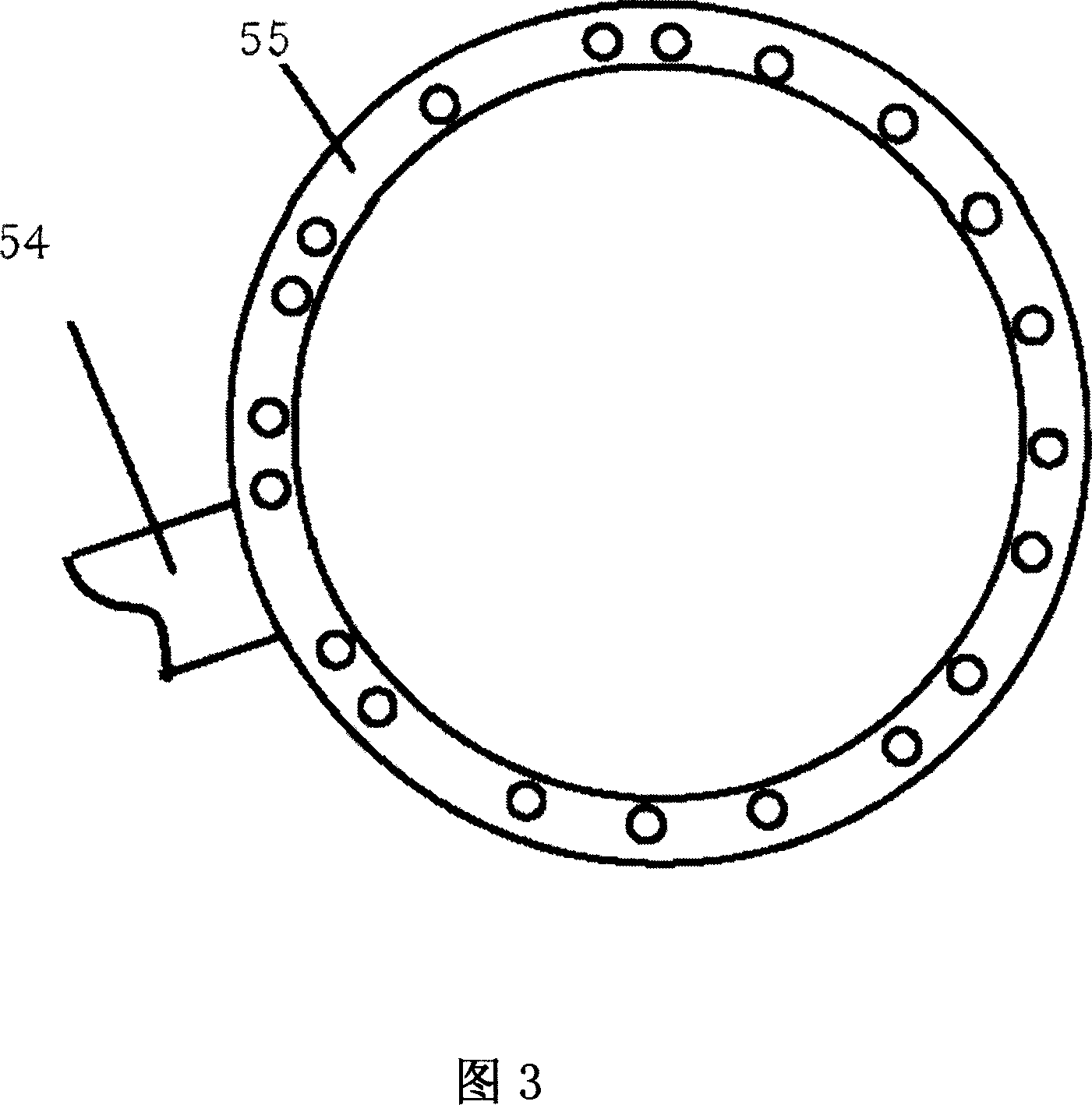

[0033] The method for casting a thin-wall cooling water jacket for a high-power diesel engine of the present invention will be described in detail below with reference to specific embodiments and drawings, but the protection scope of the present invention cannot be limited by this.

[0034] In this embodiment, the production practice of the 6S70MC cooling water jacket in a large marine diesel engine using the method for casting a thin-walled cooling water jacket for a high-power diesel engine of the present invention is taken as an example for detailed description.

[0035] The method for casting a thin-walled cooling water jacket for a high-power diesel engine of the present invention includes the following steps:

[0036] ① Use block polystyrene foam to cut and glue into a cooling water jacket model. The cooling water jacket model is manufactured by cutting and pasting block polystyrene foam according to the drawings. Because the cooling water jacket is a component of a large di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com