Double-station automatic production line of wireless chargers

A technology of wireless chargers and automated production lines, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, conveyor objects, etc., can solve the problems of low efficiency of automatic integrated assembly and high production costs, so as to improve the production efficiency of manufacturers and save Effects of labor costs and reduction in the number of assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

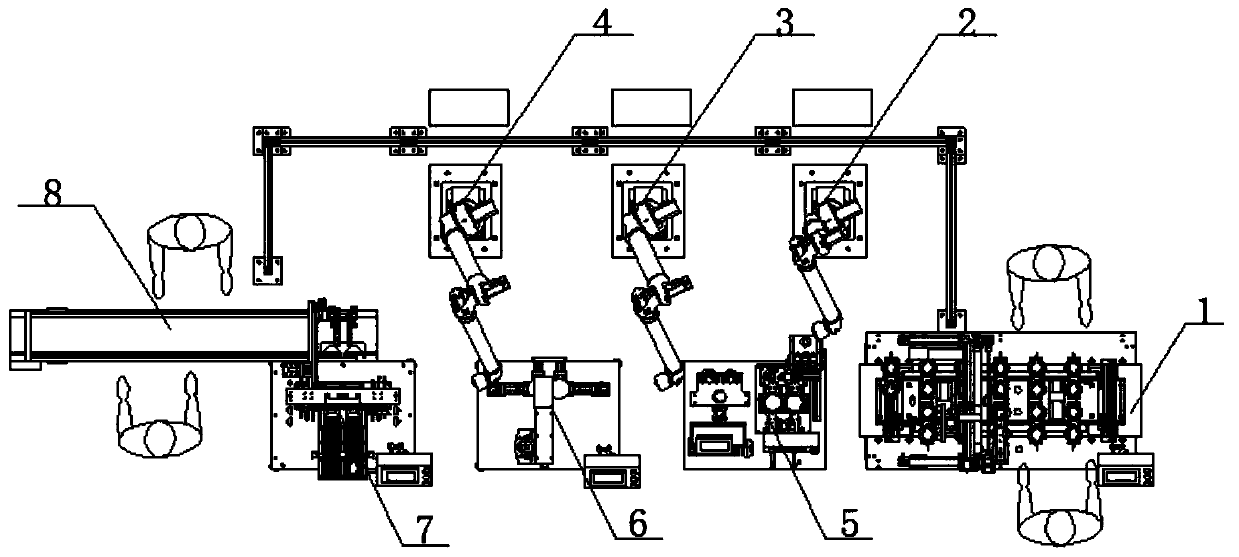

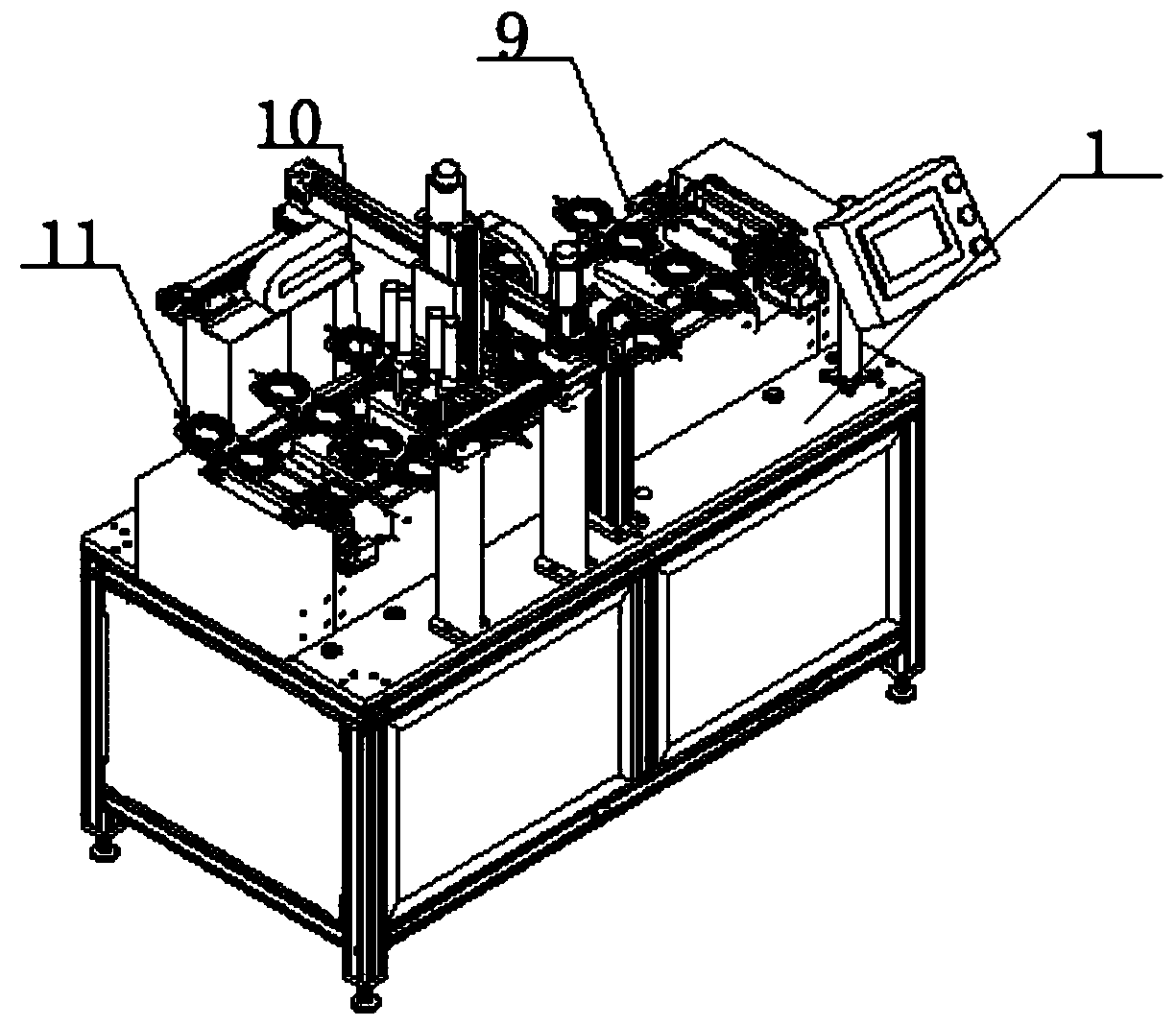

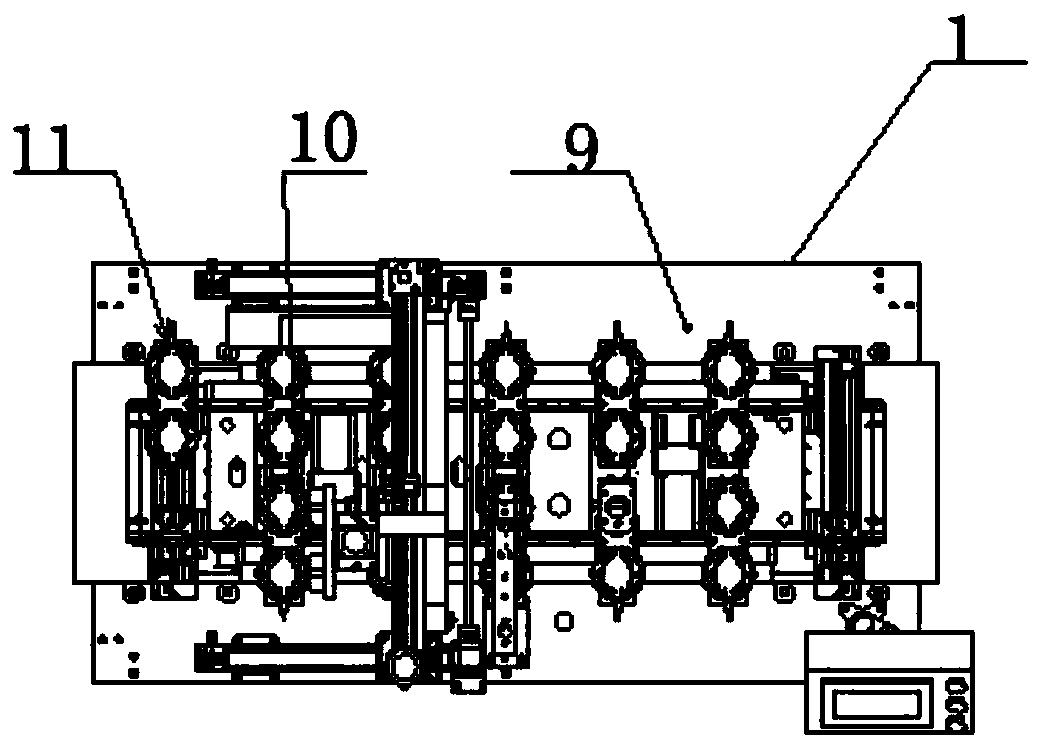

[0030] Such as Figure 1-12 As shown, a double-station wireless charger automatic production line includes No.1 robot 2, No. Radium engraving module 6, typec automatic charging detection module 7 and finished product discharge conveyor belt 8, the radium engraving module 6 is provided on one side of the feeding and conveying dispensing double station 1, and the feeding and conveying dispensing double station 1 is connected with the The upper cover visual deviation correction cover module 5 is arranged between the radium engraving modules 6, and the typec automatic charging detection module 7 is provided on one side of the radium engraving module 6, and the finished product discharge is installed on the side of the typec automatic charging detection module 7 through the rack Conveyor belt 8, the other side of the feeding and dispensing double station 1 is installed with a No. 1 robot 2 through the mounting seat, and the other side of the laser engraving module 6 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com