Electric fixture for workpiece machining and detection

A workpiece and electric technology, applied in the direction of workpiece clamping devices, manufacturing tools, measuring devices, etc., can solve the problems of low automation, reduced work efficiency, cumbersome processing procedures, etc., to reduce labor intensity, improve work efficiency, and reduce detection Effect of People and Detection Tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

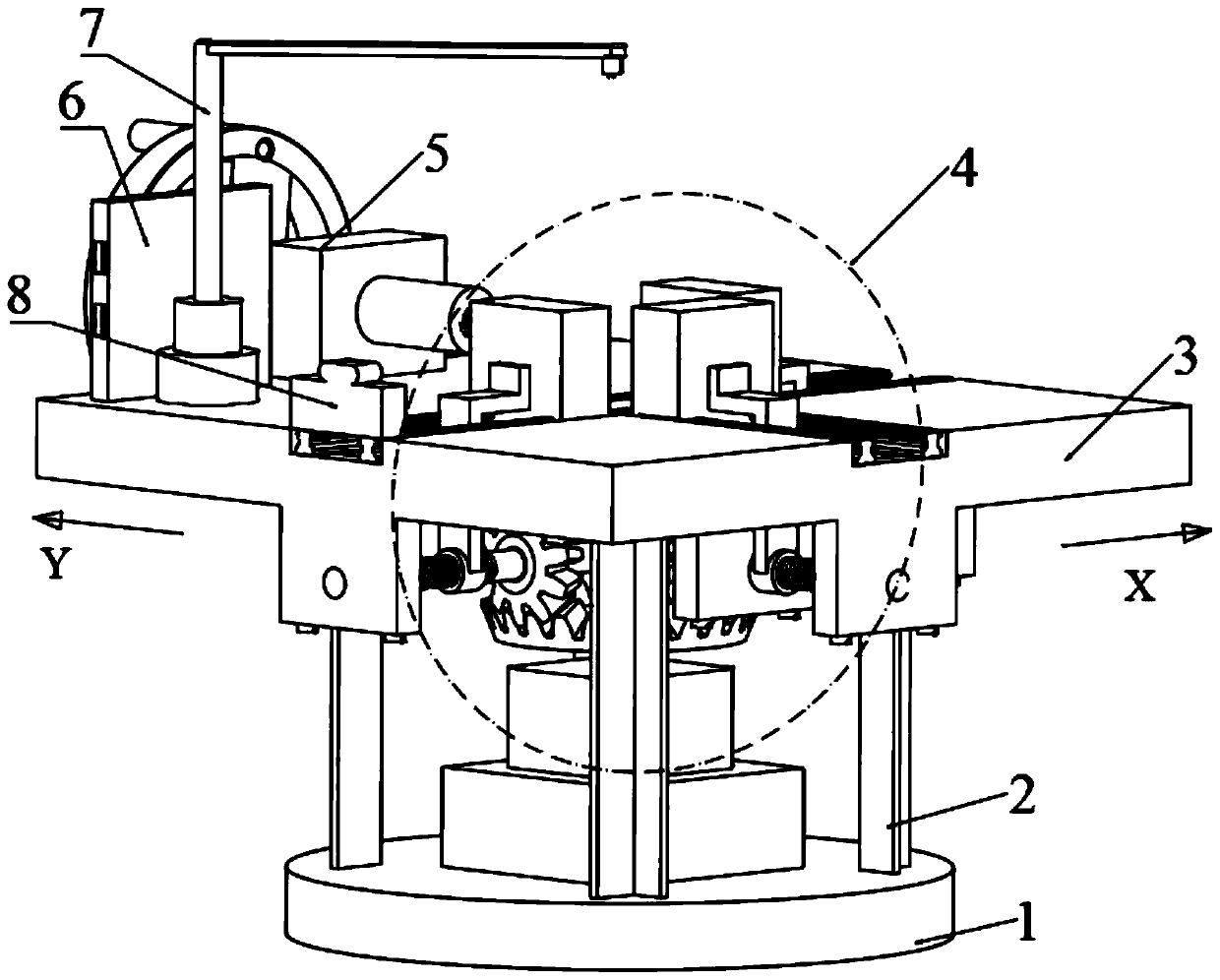

[0026] see figure 1 , including a base 1, a bracket 2, a platform 3, a clamping mechanism 4, a locking mechanism 5, a controller 6, a measuring device 7, and an anti-collision detection device 8, wherein: the clamping mechanism 4 is installed on the base 1, and the platform 3 Install the base 1 through the bracket 2, the locking mechanism 5 is fixed on the platform 3, the controller 6 is fixed on the platform 3, the measuring device 7 is fixed on the platform 3 close to the controller 6, and the anti-collision detection device 8 is fixed on the On the side of the stopper I413 of the clamping mechanism 4 and near the edge of the platform 3;

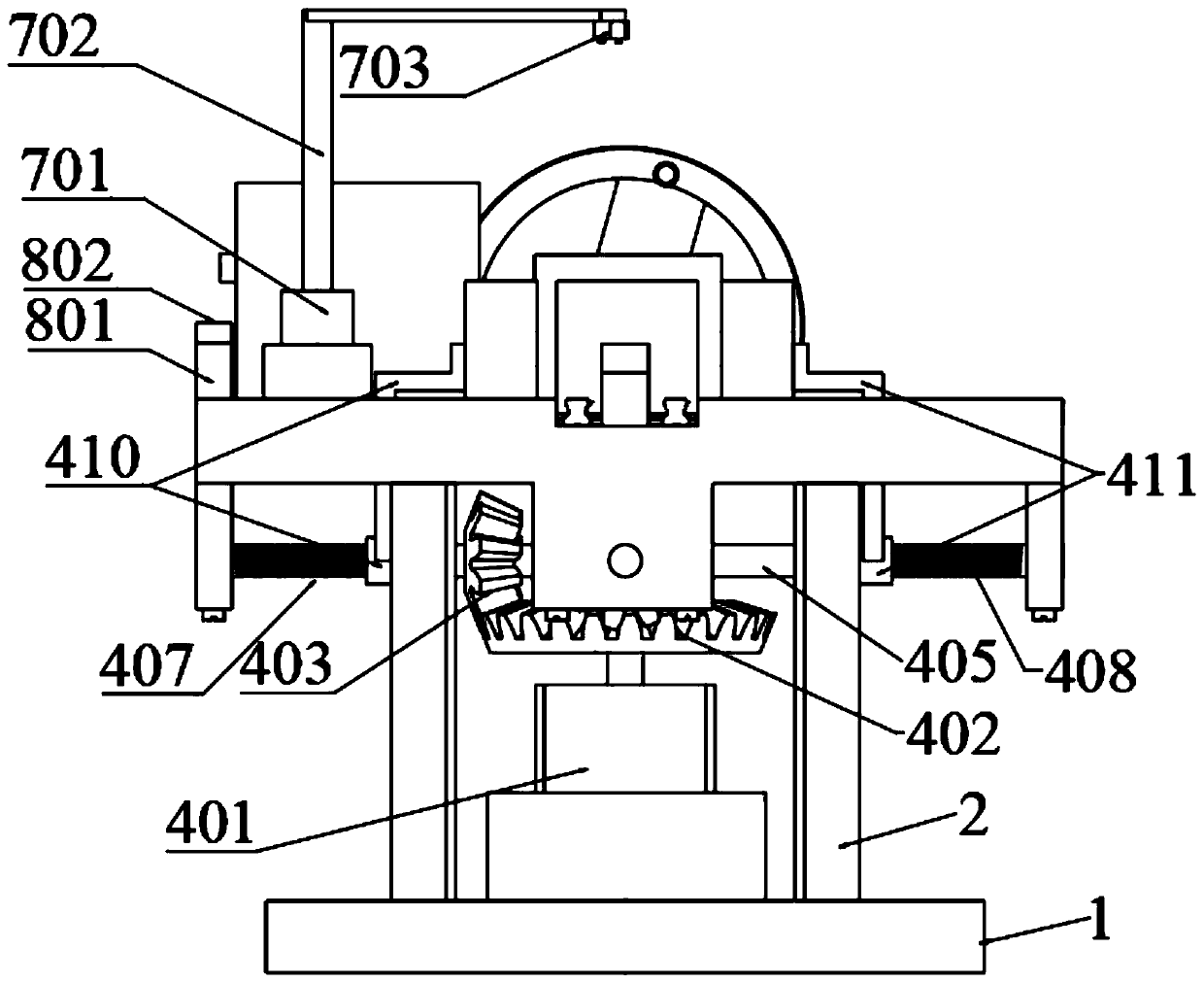

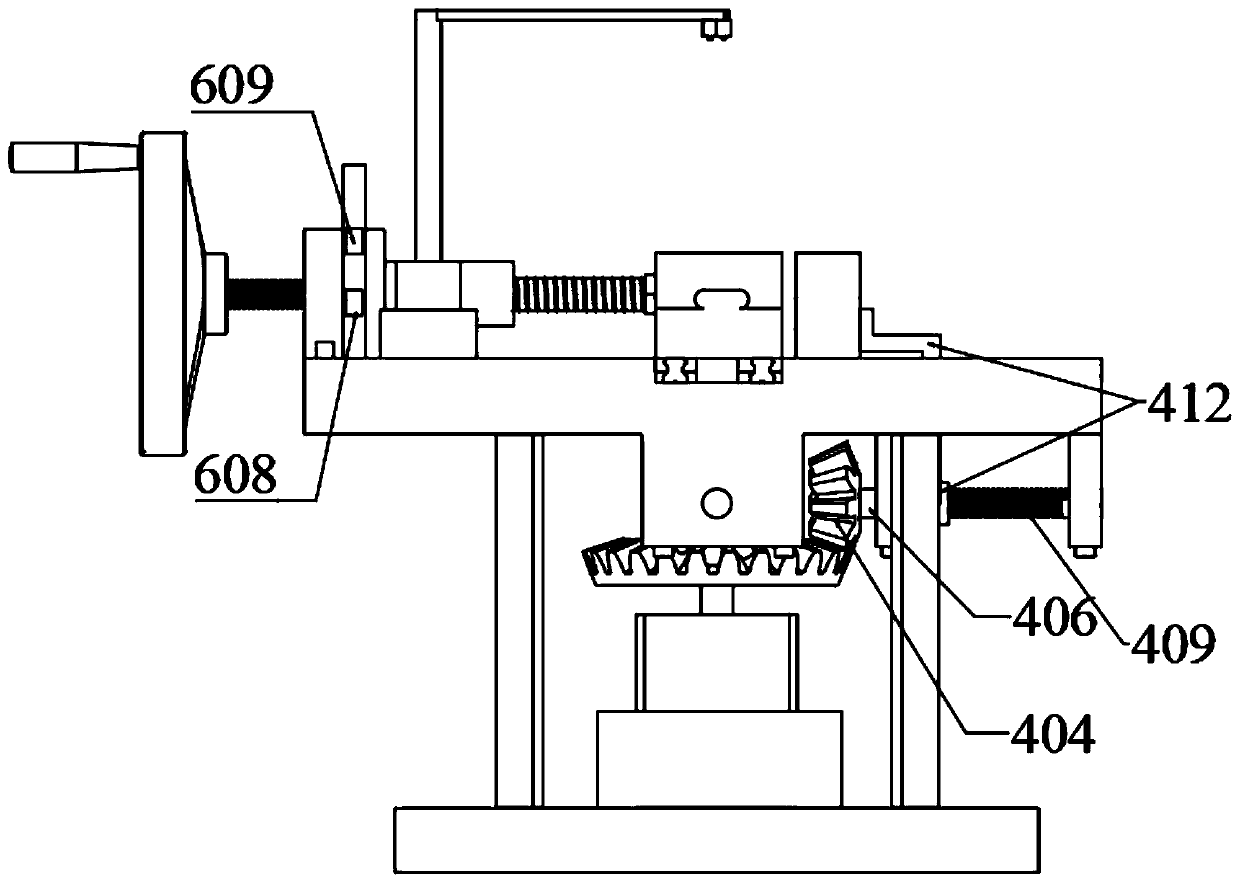

[0027] see figure 2 , 3 , 4, the clamping mechanism 4 includes a motor I401, bevel teeth I403, bevel teeth II404, bevel teeth III402, screw I405, screw II 406, connector I410, connector II411, connector III412, block I413, block II414, block III 415, X-guiding rail 416, Y-guiding rail 417, wherein: motor I401 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com