Inspection well production process with bottom

A production process and inspection well technology, which is applied in artificial islands, manufacturing tools, water conservancy projects, etc., can solve problems such as multiple molds, and achieve the effect of reducing consumption and smoothing the outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

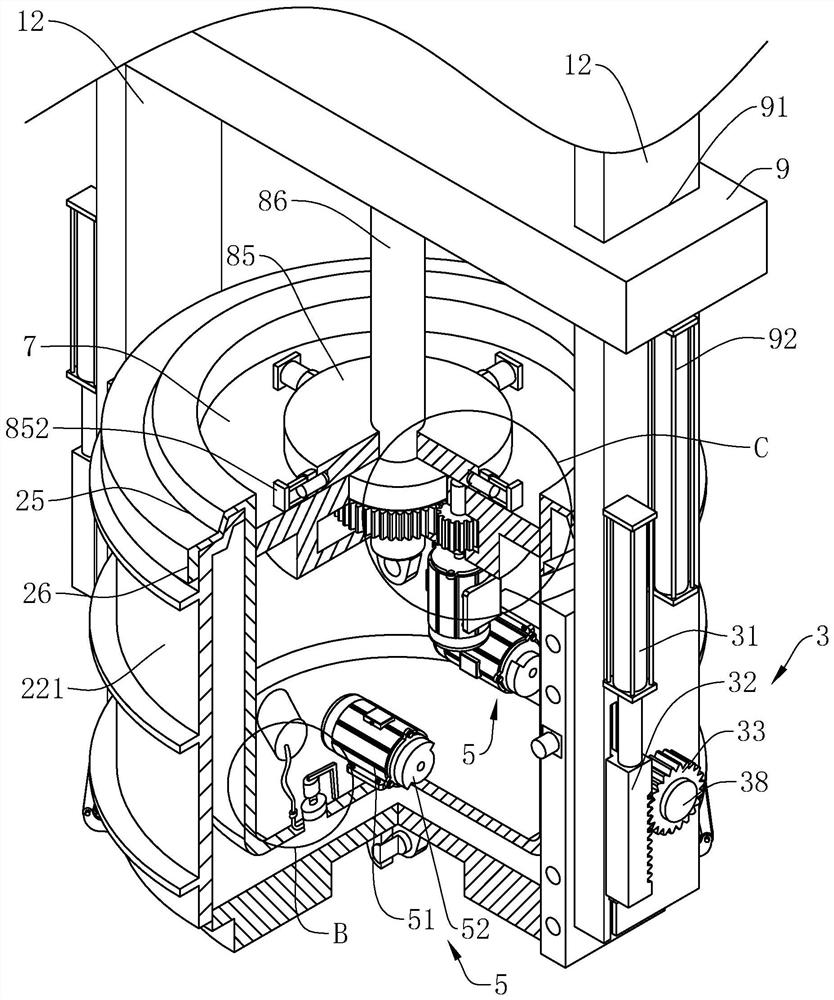

[0036] Embodiment 1: Reference figure 1 , is a kind of inspection well production equipment with a bottom disclosed by the present invention, comprising a hanger 1, a mold 2 is arranged on the lower part of the hanger 1, the mold 2 is rotatably supported on the hanger 1, and the mold 2 is mounted on the hanger 1 The rotation axis is arranged horizontally, and the overturning device 3 is fixedly arranged on the hanger 1, and the overturning device 3 is used to drive the mold 2 to rotate vertically by 180 degrees, so that the mold 2 is turned up and down.

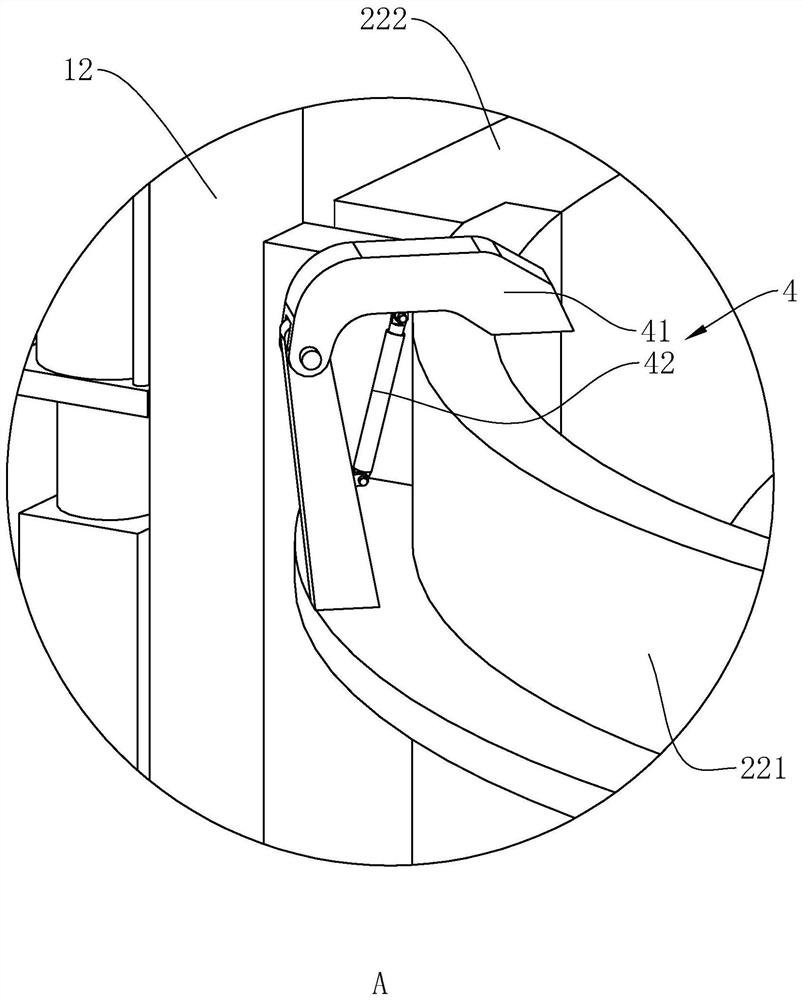

[0037] refer to figure 1 and image 3 , the mold 2 comprises an inner mold 21, an outer mold 22 and a bottom template 23, the inner mold 21 is a cylindrical barrel shape, the diameter of the inner mold 21 is less than the inner diameter of the outer mold 22, and the outer mold 22 is set outside the inner mold 21 and is connected with the inner mold. The molds 21 are arranged on the same axis, so that a pouring space 24 is f...

Embodiment 2

[0043] Embodiment 2: A production process for inspection wells with a bottom, using the production equipment for inspection wells with a bottom in Embodiment 1, including the following steps, first prepare concrete and steel cages, and collapse the prepared concrete The concrete slump is less than 10mm; the cylindrical inner mold 21 is hoisted on the ground, and the bottom of the inner mold 21 faces upwards, and then the bound steel cage is installed outside the inner mold 21, and an inspection well is installed at the same time The embedded part, the outer mold 22 is combined into a circular sleeve on the outside of the inner mold 21, so that a pouring space 24 is formed between the outer mold 22 and the inner mold 21, and the upper end of the outer mold 22 is higher than the upper end of the inner mold 21; Qualified concrete is poured into the pouring space 24. During the pouring process, the vibrating device 5 located on the side wall of the inner mold 21 is first started to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com