A guide docking member for battery power transmission

A technology for docking components and battery power, applied to battery pack parts, structural parts, conductive connections, etc., can solve problems such as poor contact between output joints and butt joints, wear and tear between output joints and butt joints, and avoid poor contact and structure Ingenious, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

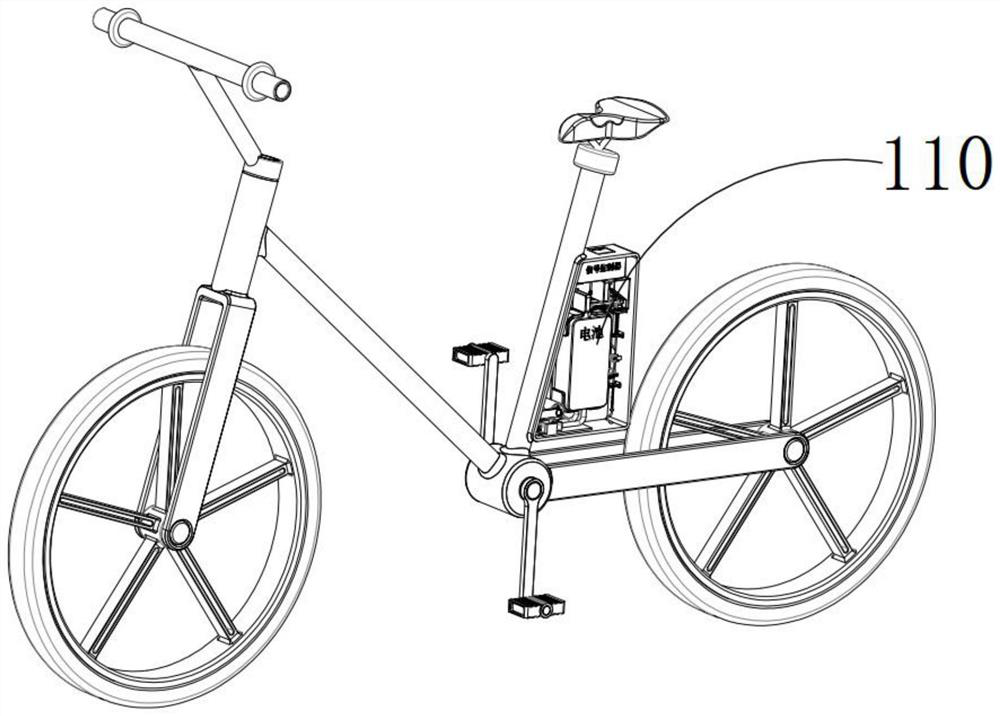

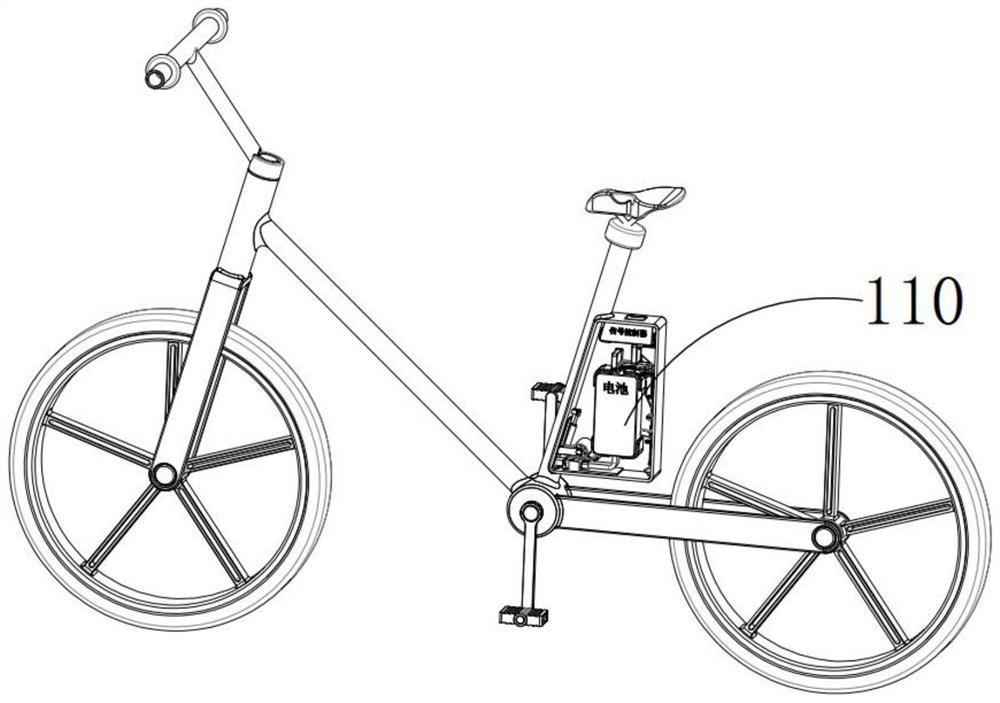

[0060] The function of the shared moped battery mainly includes two aspects, one is to supply power to the power booster motor, and the power booster motor starts to drive the moped; the other is to supply power to the feedback system, which monitors the power of the battery. When the battery power is low, the feedback system will remotely feed back the signal to the background management office to remind the maintenance personnel to replace the battery of the shared moped.

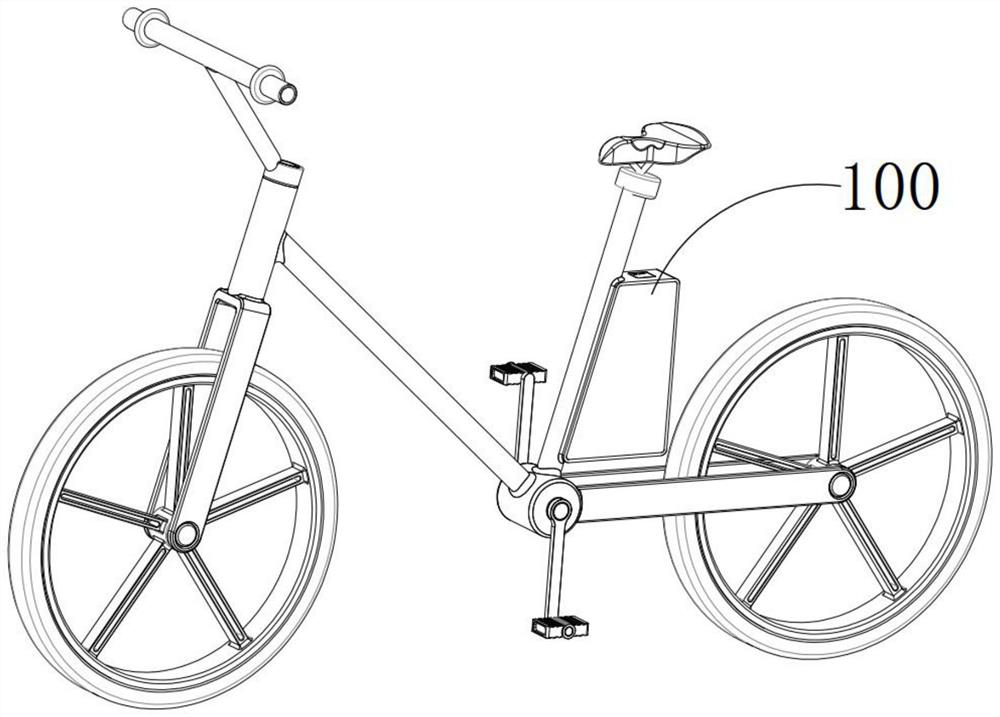

[0061] A manual installation and automatic docking system for a shared moped battery, which includes an installation box 100 fixedly connected to the body of the shared moped. The installation box 100 contains a detachable rectangular battery 110 and a power supply input terminal docking mechanism 120 of the power booster motor. 1. The power supply input terminal docking mechanism 2 130 of the feedback system, wherein the battery 110 includes a first power supply output terminal docked with the docking mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com