A kind of preparation method of low elastic modulus medical titanium alloy ingot

A low elastic modulus, titanium alloy technology, applied in the field of medical bio-titanium alloy preparation, can solve the problems of difficulty in ensuring the accuracy and uniformity of alloy composition, segregation of tantalum and niobium elements, and difficulty in alloy preparation, so as to avoid high melting point Effect of element segregation and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a low elastic modulus medical titanium alloy ingot, the steps are as follows:

[0027] Step 1: Prepare raw materials. First, prepare different thickness plates or foils according to the melting point of Ti plate, Zr plate, Nb plate, and Ta plate. The thickness of Ta plate (foil) is required to be ≤1mm; Ti plate, Zr plate, and Nb plate (Foil) has a thickness of 1 to 6 mm.

[0028] Step 2: Calculate the weight of the required plate according to the ratio weight of each element in the TiNbTaZr alloy, and cut the plate into strips of the same length and width.

[0029] Step 3: arrange the slats prepared in step 2 in a cross-arrangement, requiring Ta boards to be placed in the middle, and arrange Nb boards, Zr boards, and Ti boards in sequence on both sides of the Ta boards.

[0030] Step 4: Clamp the sheets arranged in step 3 with a fixture, and assemble and weld them in a vacuum plasma welding box to form a consumable electrode.

[0031] Step 5: Pr...

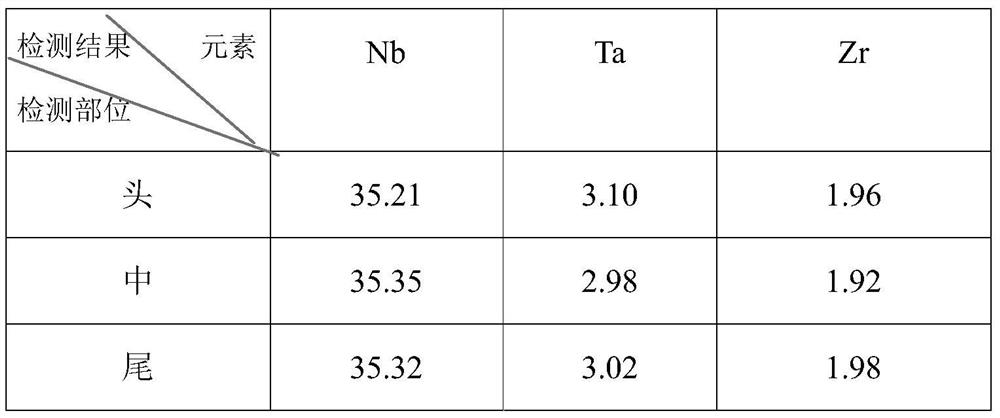

Embodiment 1

[0038] Taking the preparation of Ti35Nb2Ta3Zr alloy as an example, feeding 60kg, using a vacuum consumable electric arc furnace with a maximum feeding capacity of 100kg for melting, the preparation steps are as follows:

[0039] Step 1: After calculation, it is necessary to prepare 4 consumable electrodes for the preparation of Ti35Nb2Ta3Zr alloy. The required plates are as follows: Ti plate size 4×60×750mm, 44 pieces in total, weight 35.6kg; Nb plate size 1.3×60×750mm, A total of 44, weighing 21.6kg; Ta foil size 0.4×60×750mm, a total of 4 pieces, weighing 1.2kg; Zr plate size 1.6×60×750mm, a total of 4 pieces, weighing 1.88kg.

[0040] Step 2: Prepare the required plates according to the calculation results of Step 1.

[0041] Step 3: The plates prepared in step 2 are divided into 4 parts, each part includes 11 Ti plates, 11 Nb plates, 1 Ta foil, and 1 Zr plate. Arrange the divided sheets in the following way: put the Ta foil in the middle, place the Nb, Zr and Ti boards in...

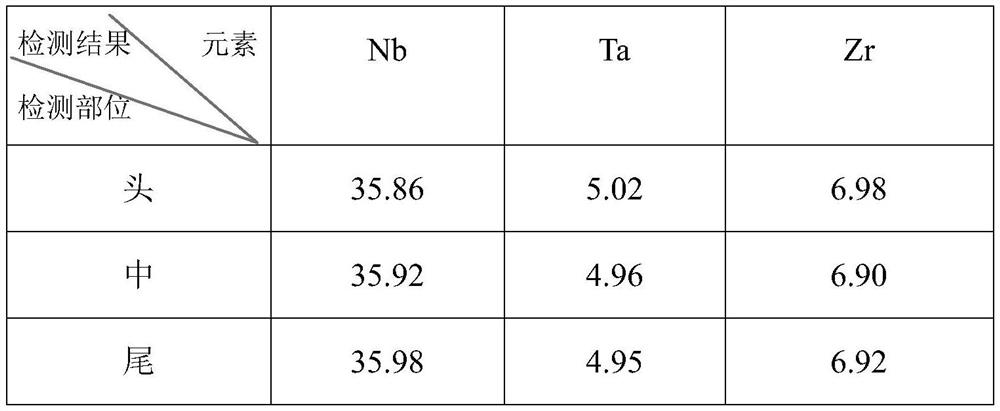

Embodiment 2

[0052] Taking the preparation of Ti36Nb5Ta7Zr alloy as an example, feeding 60kg, using a vacuum consumable electric arc furnace with a maximum feeding capacity of 100kg for melting, the preparation steps are as follows:

[0053] Step 1: After calculation, two consumable electrodes are required to prepare Ti36Nb5Ta7Zr alloy. The required plates are as follows: Ti plate size 3.5×60×750mm, 44 pieces in total, weight 31.2kg; Nb plate size 1.3×60×750mm, A total of 44, weighing 21.6kg; Ta foil size 0.5×60×750mm, a total of 8 pieces, weighing 3kg; Zr plate size 1.8×60×750mm, a total of 8 pieces, weighing 4.2kg.

[0054] Step 2: Prepare the required plates according to the calculation results of Step 1.

[0055] Step 3: The plates prepared in step 2 are equally divided into 4 parts, and each part includes 11 Ti plates, 11 Nb plates, 2 Ta foils, and 2 Zr plates. Arrange the divided sheets in the following way: put the Ta foil in the middle, place the Zr board, Nb board and Ti board in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com