Spin coating equipment for uniformly coating photoresist on surface of super-large and super-heavy substrate

A technology of substrate surface and photoresist, which is applied to the device for coating liquid on the surface, the coating equipment of photoengraving process, coating and other directions to achieve the effect of improving the uniformity of glue coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

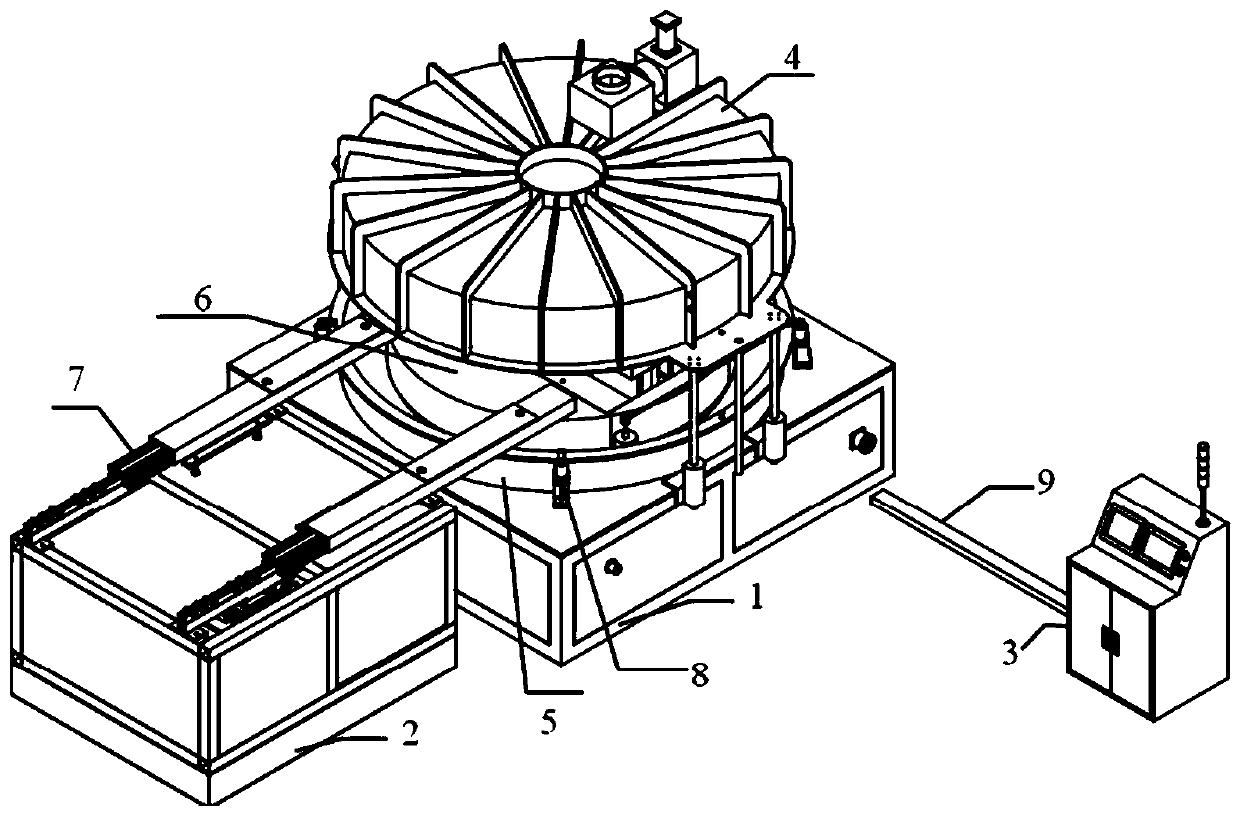

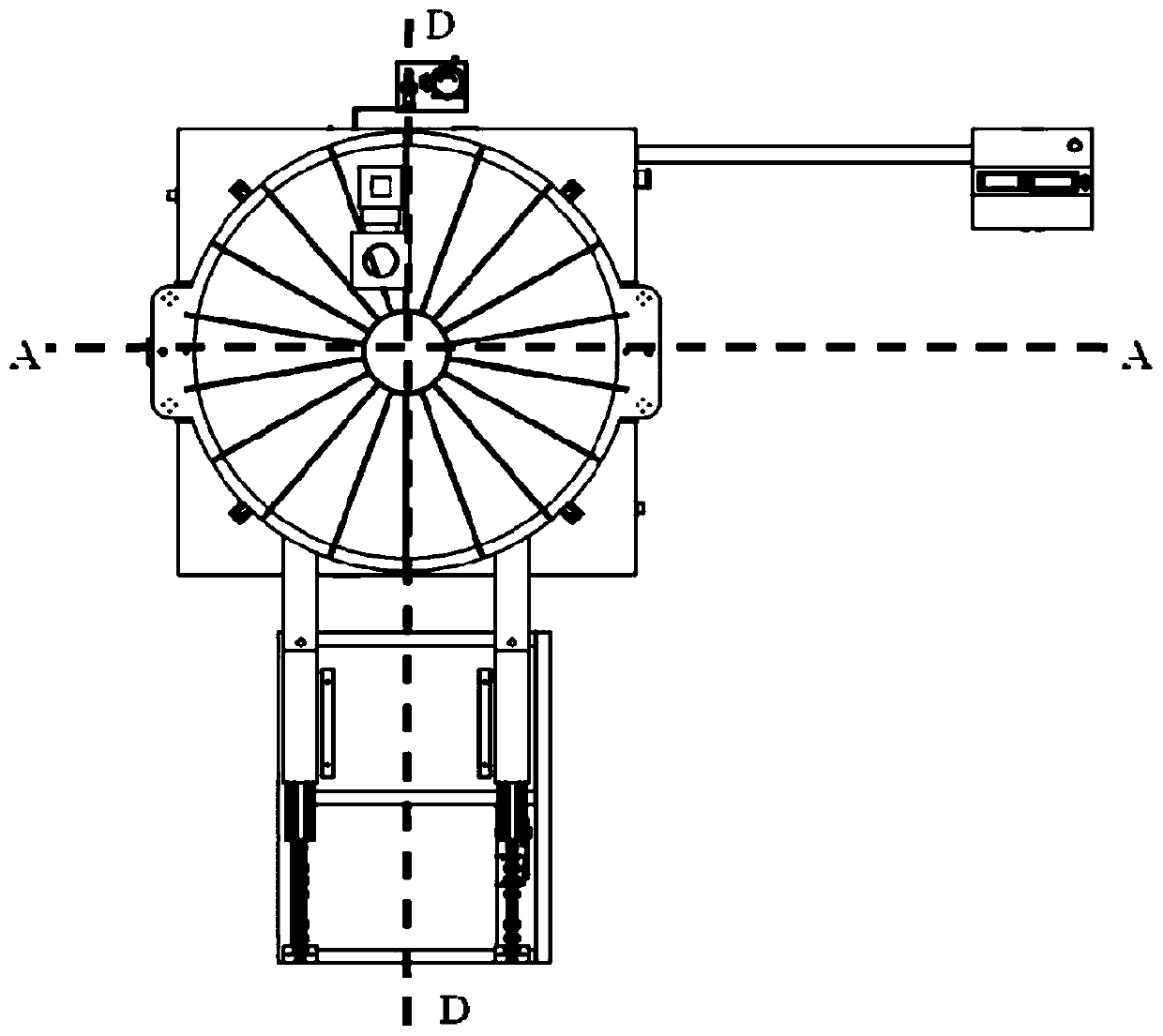

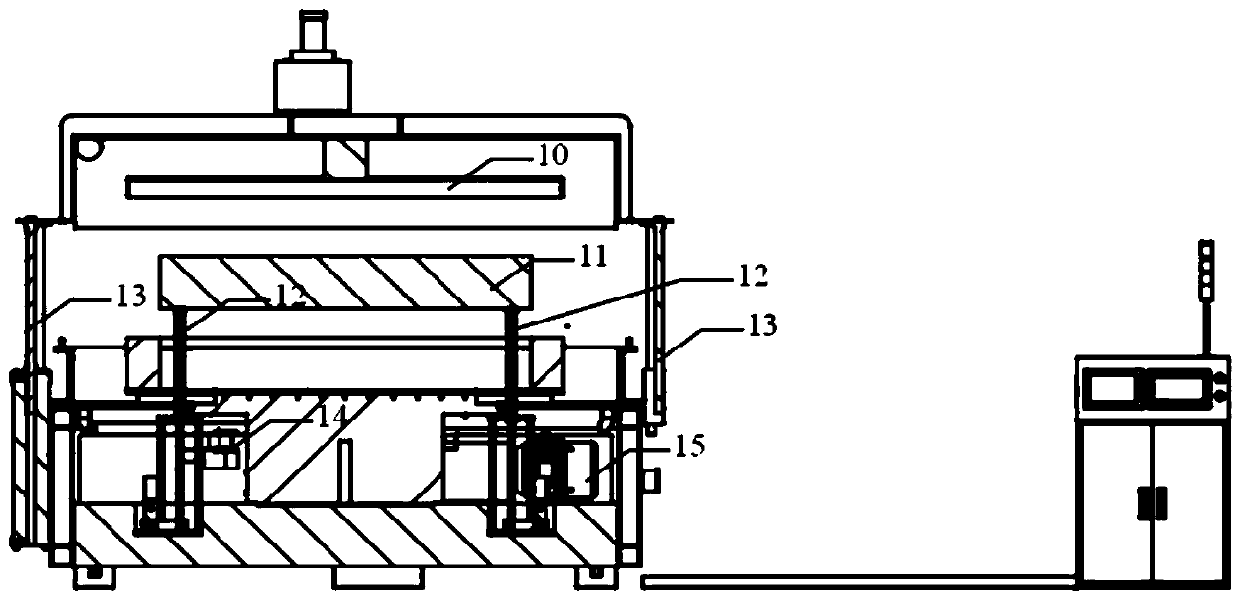

[0035] figure 1 Shown is the overall structure schematic diagram of the present invention, figure 2 is a top view of the device of the present invention. It can be seen from the figure that the spin coating equipment for uniform coating of photoresist on the surface of super large and super heavy substrates of the present invention is mainly composed of three parts: spin coating host 1, sample loading and unloading system 2, and master control system 3. combine image 3 and4 , the spin coating host 1 includes an upper cover 4, a glue coating chamber 5, a gluing turntable 6, a synchronous cover 10, a first jacking device 12, an upper cover jacking device 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com