Boiler NOx prediction method based on MI-LSTM

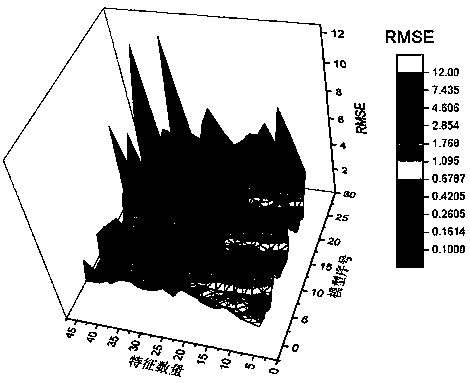

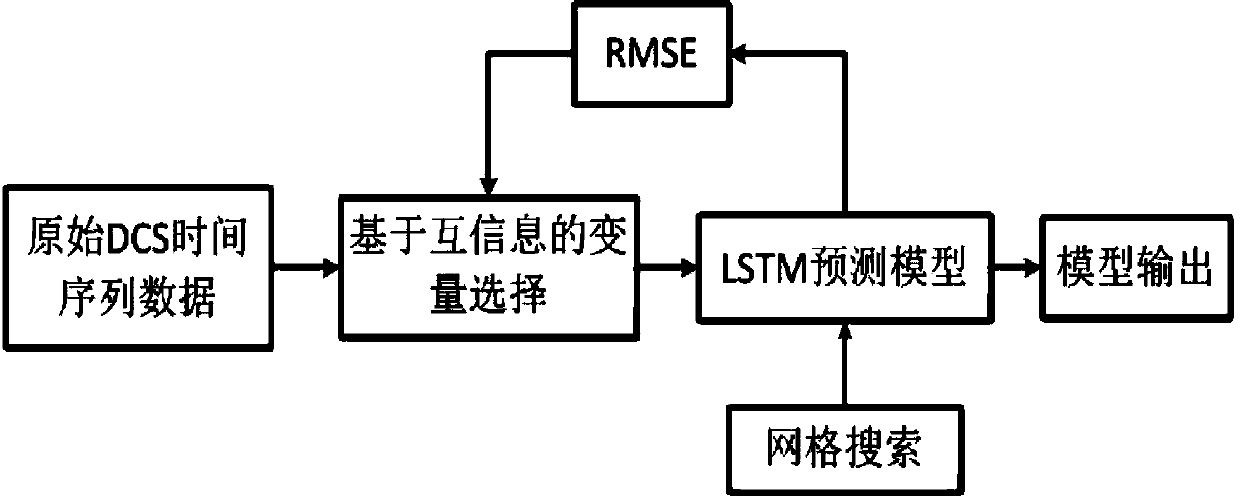

A prediction method and boiler technology, applied in neural learning methods, chemical process analysis/design, biological neural network models, etc., can solve problems such as inaccurate models, affecting model prediction accuracy, and dimensional disasters, and reduce model complexity. The effect of improving model accuracy and generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

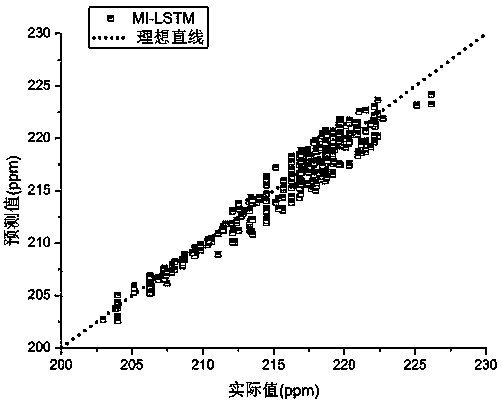

[0034] Power Station BoilerNO x Emission is affected by multiple thermal variables, and the variables have correlations and the time series characteristics of on-site data. x The emission is predicted dynamically. In this example, the data of a 660MW unit of a coal-fired power plant in Henan is used as an example. The combustion method of the boiler is the front and rear wall hedging combustion. There are 6 layers of burners (3 layers in the front and rear walls), and each layer has 6 swirl burners. The wall is layer D, E, and F from bottom to top, and each medium-speed coal mill provides air-pulverized mixture for 6 pulverized coal burners on the same layer. At the same time, one layer of exhaust air is arranged above the swirling pulverized coal burners on the front and rear walls, and each layer has 6 exhaust air (AAP) nozzles and 2 side exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com