Hydraulic spring operating mechanism

A technology of operating mechanism and hydraulic spring, applied in the direction of protection switch operation/release mechanism, power device inside the switch, etc., can solve problems such as energy waste, seal failure, etc., to improve structure compactness, reduce waste, and reduce parts Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

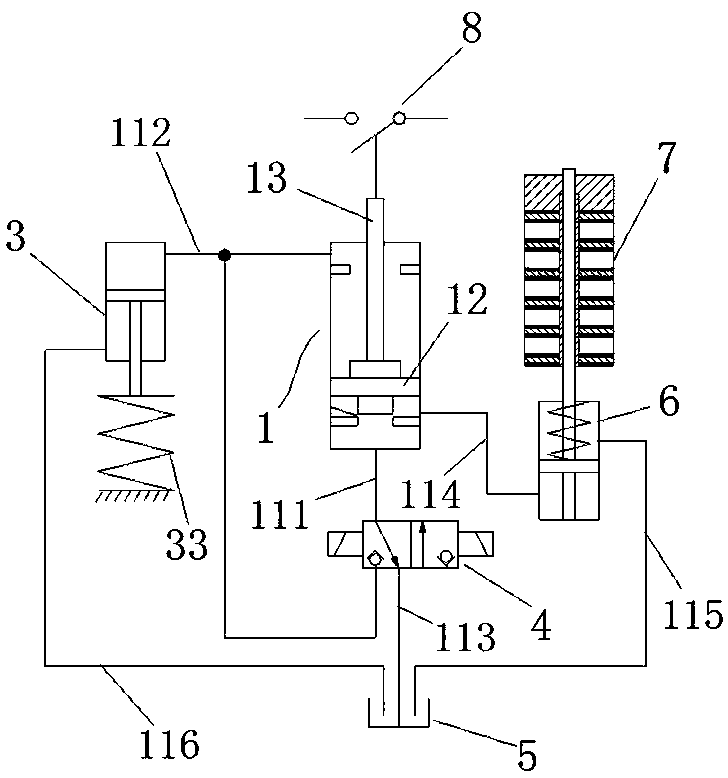

[0034] The hydraulic spring operating mechanism in this embodiment is used to control the closing and opening of the high voltage circuit breaker.

[0035] Such as figure 1 As shown, the hydraulic spring operating mechanism includes a working cylinder 1, a spring energy storage device 3, a hydraulic system, a power generation piston cylinder 6 and a power generation device 7, and the hydraulic system includes an electromagnetic reversing valve 4, a fuel tank 5 and an oil circuit connecting each device .

[0036] Such as figure 2 As shown, the working cylinder 1 includes a cylinder body 11 and a differential piston 12. The cylinder body 11 is provided with a working cylinder inner cavity for the differential piston 12 to move. The differential piston 12 divides the working cylinder inner cavity into an upper working high-pressure chamber 16 and the lower working differential pressure chamber 17;

[0037] Such as figure 1 with figure 2 As shown, the upper side of the diff...

Embodiment 2

[0056] The difference with Embodiment 1 is mainly that the power generating device is different, and the power generating device in this embodiment is a linear power generating device, such as Image 6 As shown, it includes a mounting frame 102 installed between the sealing plate 2 and the sealing cover 9, and multiple sets of stator coils 101 are set on the mounting frame 102, and multiple sets of stator coils 101 are arranged along the axial direction of the generating piston rod 62, An insulating ring 104 is arranged between the adjacent stator coils 101, and a sleeve-shaped permanent magnet 103 is fixedly set on the generating piston rod 62. The sealing plate 2 is provided with a perforation for the permanent magnet 103 to pass through. The permanent magnet 103 and the The sealing plate 2 is tightly fitted; during the upward movement of the generating piston 61 , the permanent magnet 103 cuts the magnetic induction lines generated by the stator coil 101 , thereby generating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com