X-ray tube cathode structure

A cathode structure, X-ray tube technology, applied in the direction of X-ray tube electrodes, X-ray tubes, X-ray tube components, etc., can solve the problems of X-ray tube failure, time-consuming disassembly and replacement, complex structure, etc. Achieve the effect of convenient installation and replacement of parts, easy disassembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described now in conjunction with accompanying drawing.

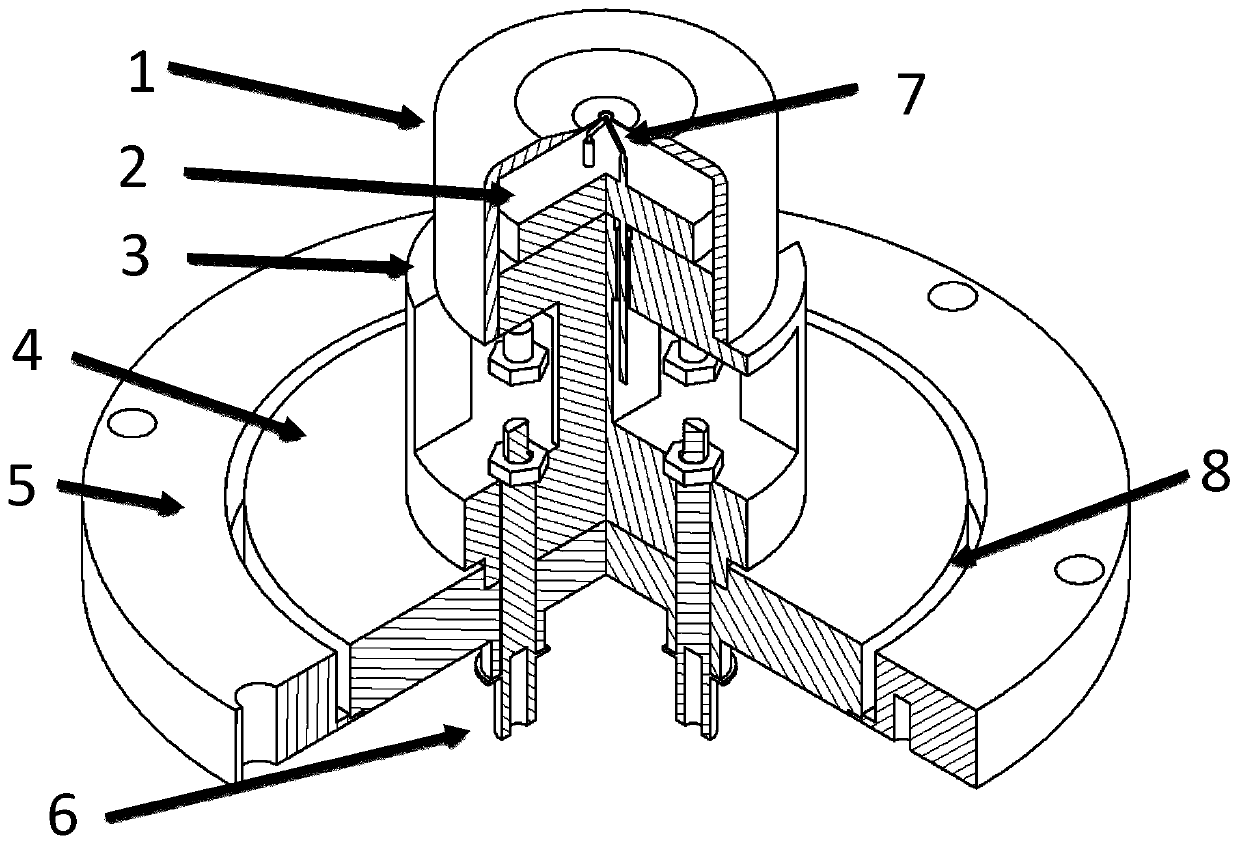

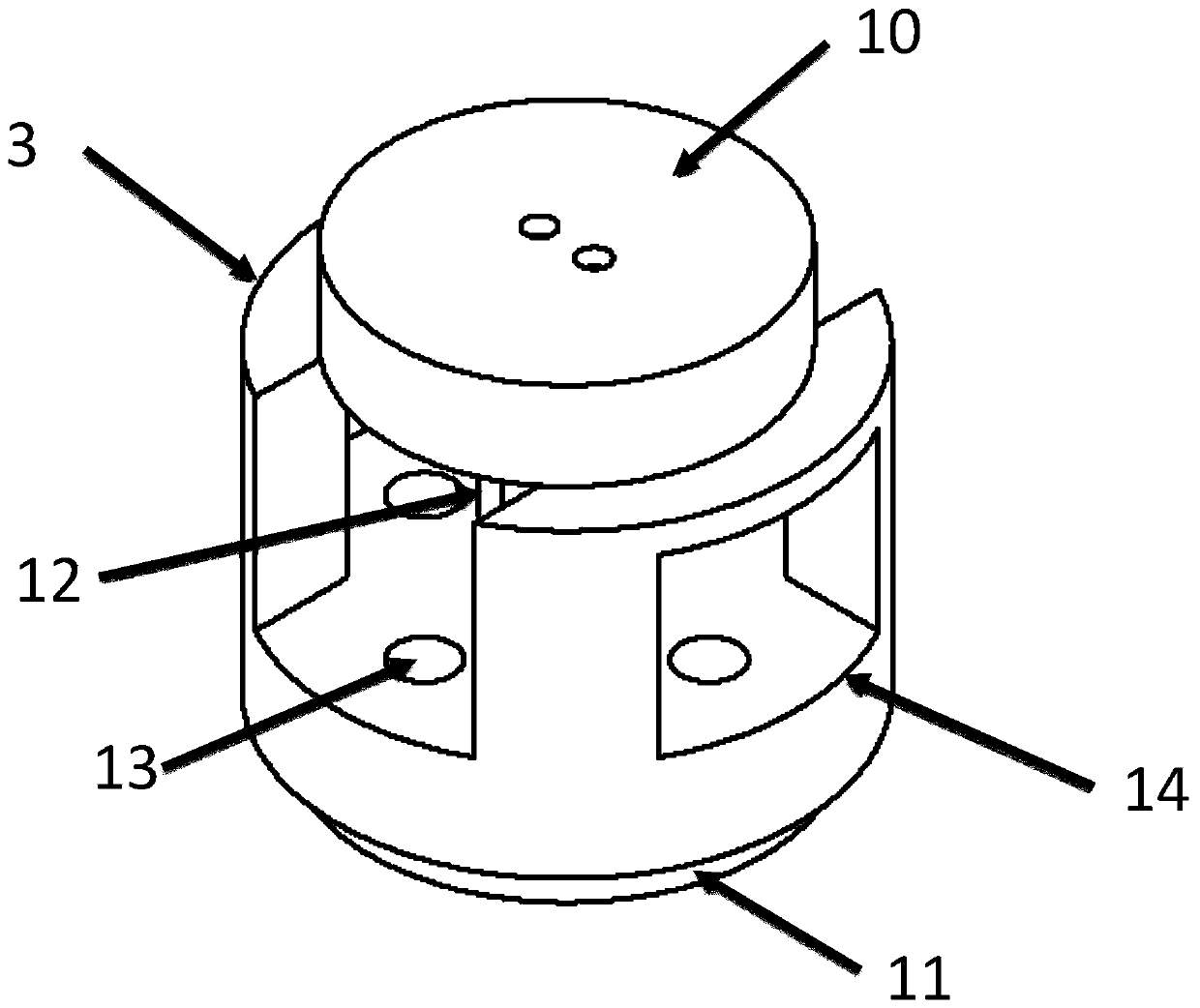

[0030] Such as figure 1 As shown, the present invention proposes an X-ray tube cathode structure, which includes: a grid 1 , a cathode wire base 2 , a transition socket 3 , a ceramic base 4 , a Kovar steel base 5 , an electrode post 6 , and a cathode wire 7 .

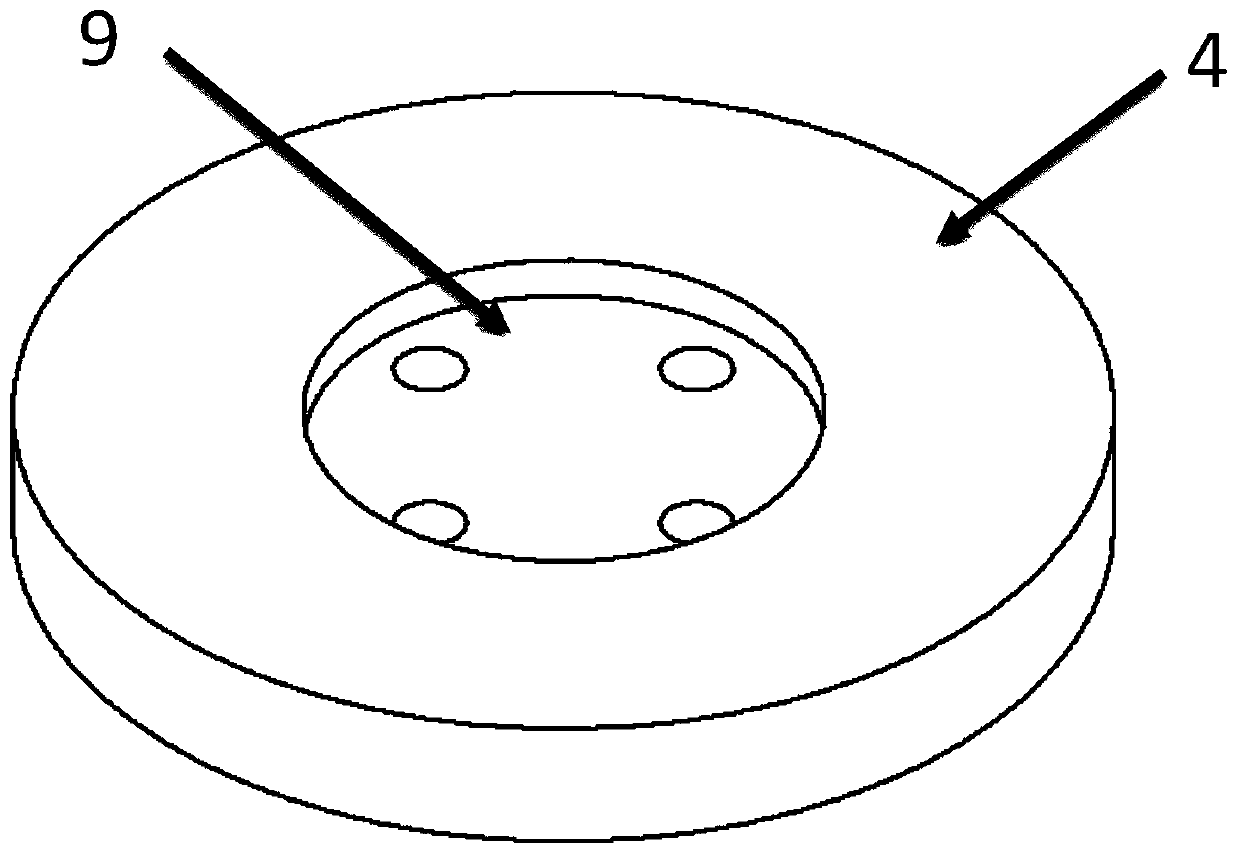

[0031] Among them, the Kovar steel base 5 is in a ring structure, and the ceramic base 4 is placed in the inner ring of the Kovar steel base 5 of the ring structure, and the two are fixed on the same horizontal plane by welding; the ceramic base 4 and the ring structure A first circular groove 8 is provided between the inner rings of the Kovar steel base 5; the transition socket 3 is fixedly installed on the ceramic base 4, and the transition socket 3 is provided with 4 electrode columns 6, which pass through the transition socket in turn 3 and the ceramic base 4 are used to insulate the X-ray tube shell, and connect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com