High-strength steel sheet and method for producing same

A technology of high-strength steel plates and manufacturing methods, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as meeting difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

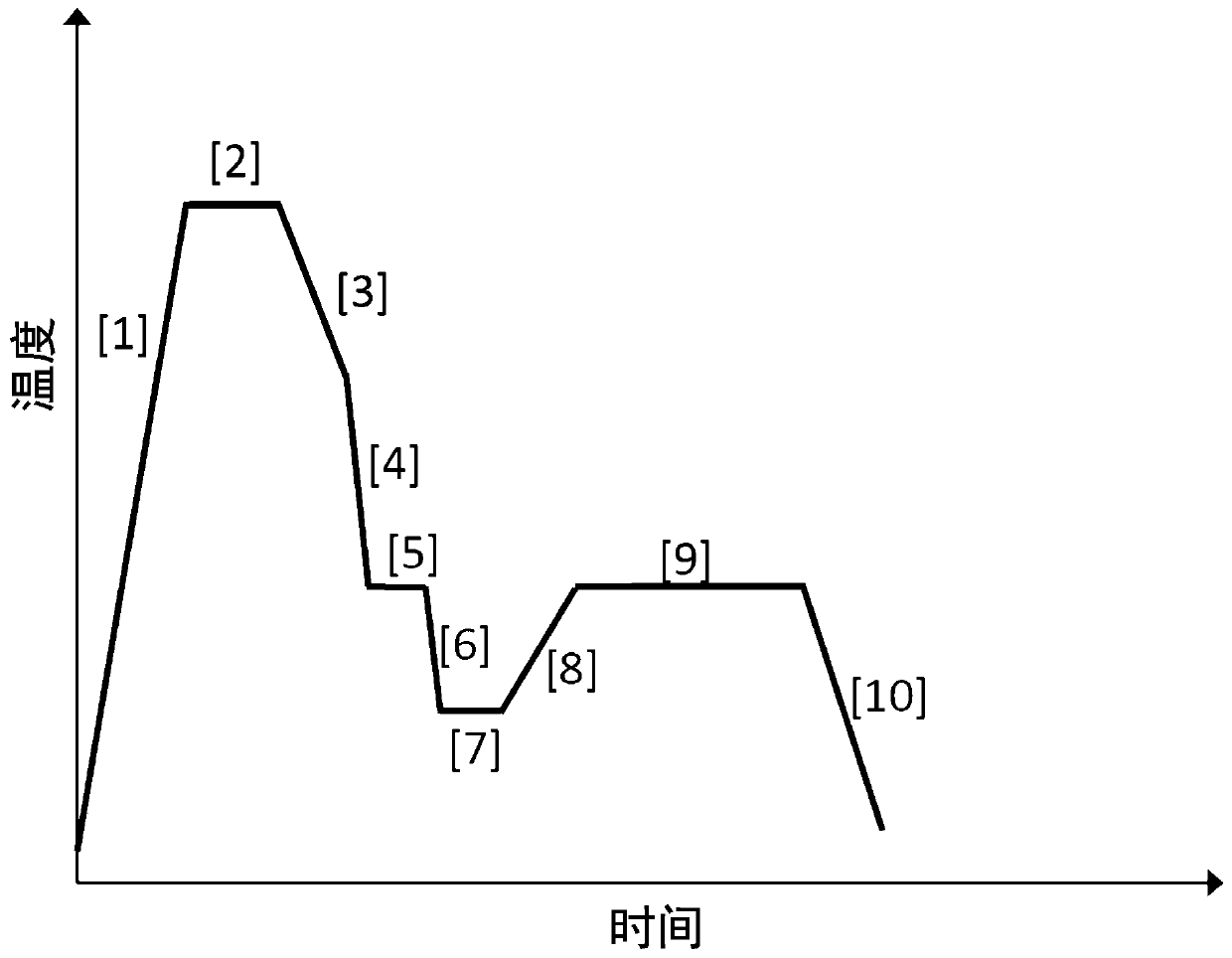

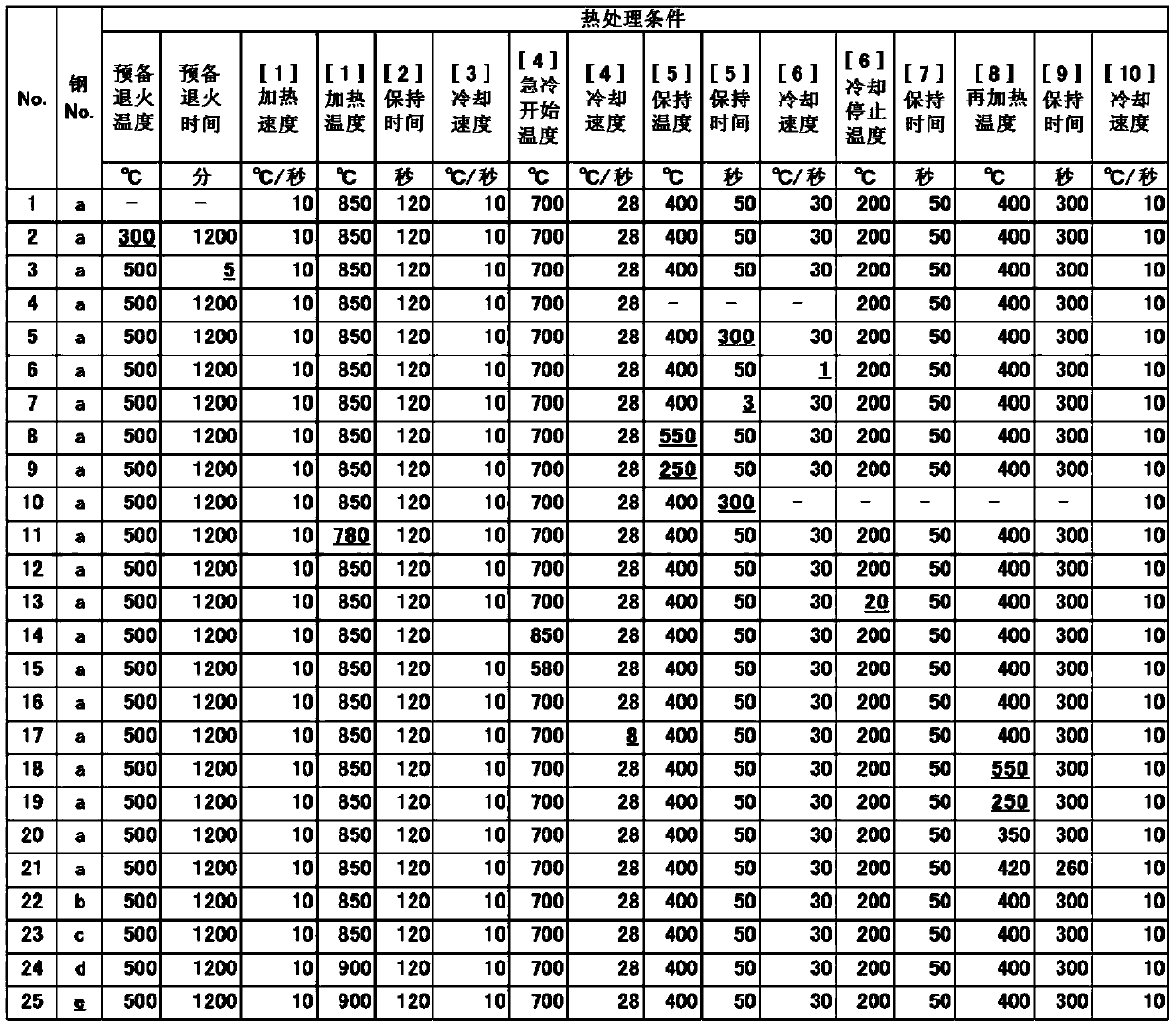

Method used

Image

Examples

Embodiment Construction

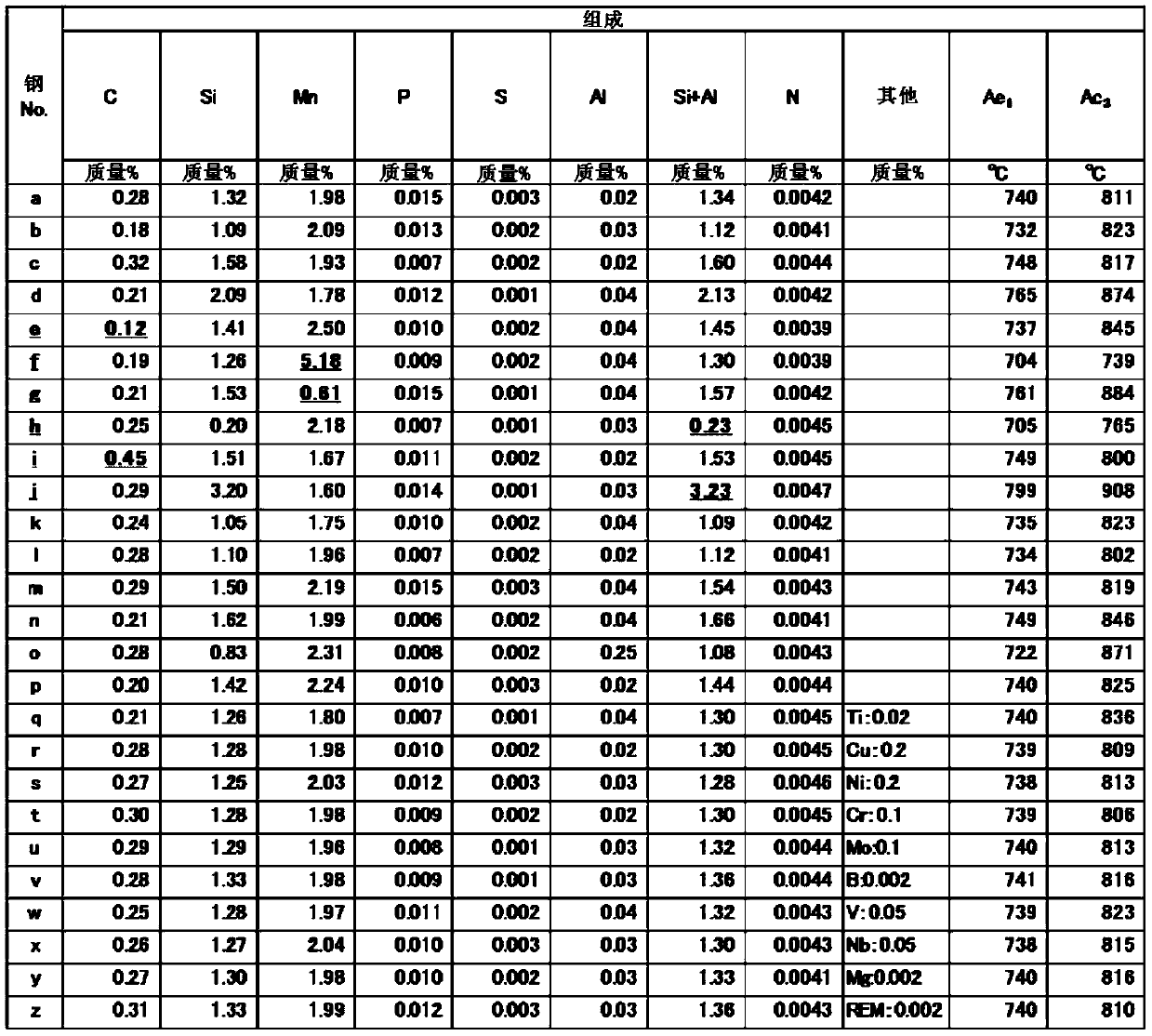

[0049] As a result of intensive research by the present inventors, in a steel having a predetermined composition, by making the steel structure (metal structure) as follows: ferrite fraction: 5% or less, tempered martensite and tempered bainite Total fraction of body: 60% or more, retained austenite content: 10% or more, average size of retained austenite: 1.0 μm or less, retained austenite with a size of 1.5 μm or more: 2 of the total amount of retained austenite % or more and the amount of dissolved nitrogen in the steel sheet: 0.002 mass % or less, the tensile strength (TS), the cross tensile strength of the welded part (SW cross tensile), the yield ratio (YR), the tensile strength can be obtained The product of (TS) and total elongation (EL) (TS×EL), LDR, and hole expansion ratio (λ) are all high-strength steel sheets at high levels.

[0050] 1. Steel structure and solution nitrogen content

[0051] Hereinafter, details of the steel structure and the amount of dissolved n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com