High-performance low-carbon bainite construction steel and producing method thereof

A low-carbon bainite and production method technology, applied in heat treatment equipment, temperature control, heat treatment process control, etc., can solve the problems of high price and high production cost, and achieve the effect of low cost, simple manufacturing process and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

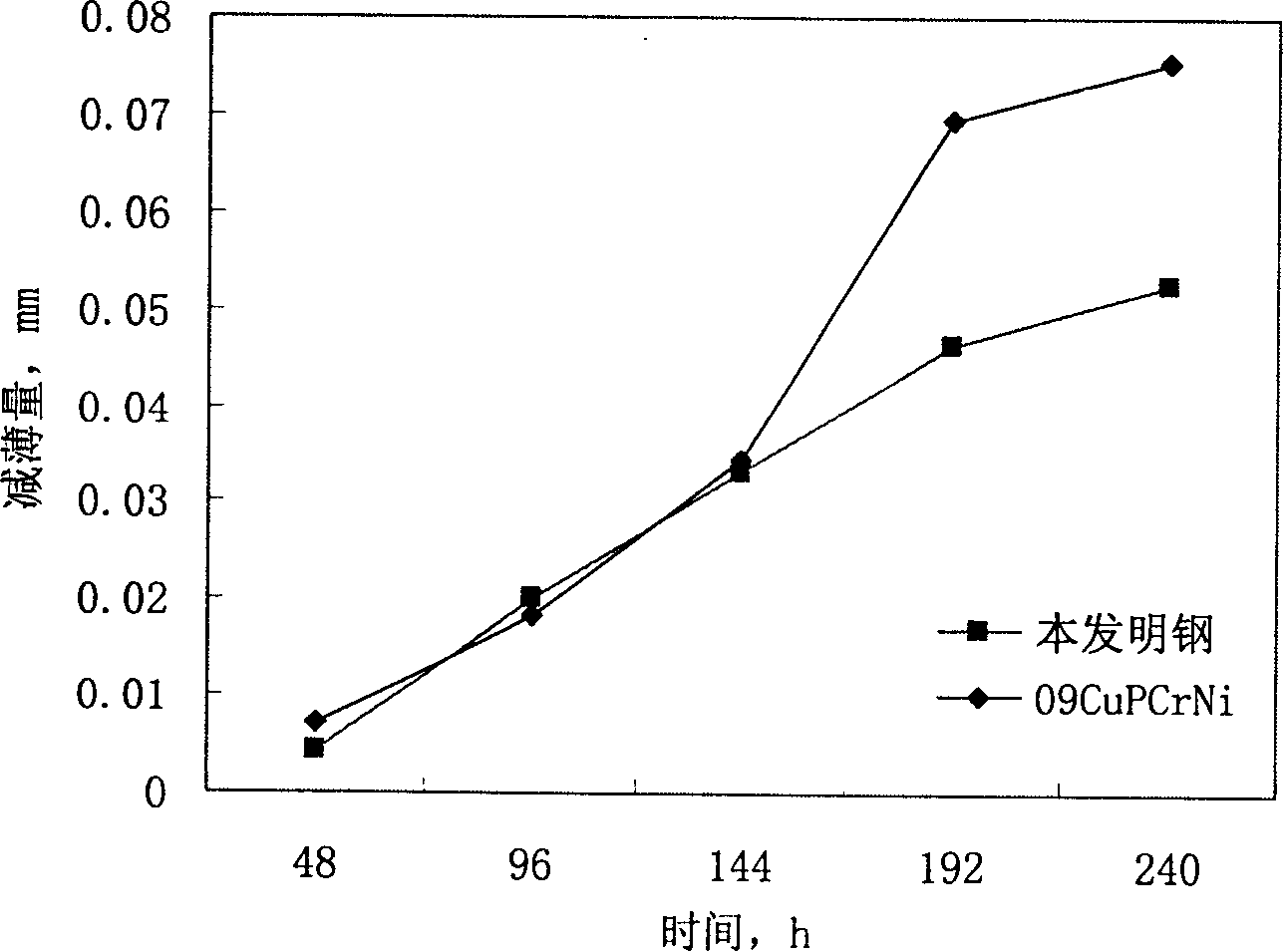

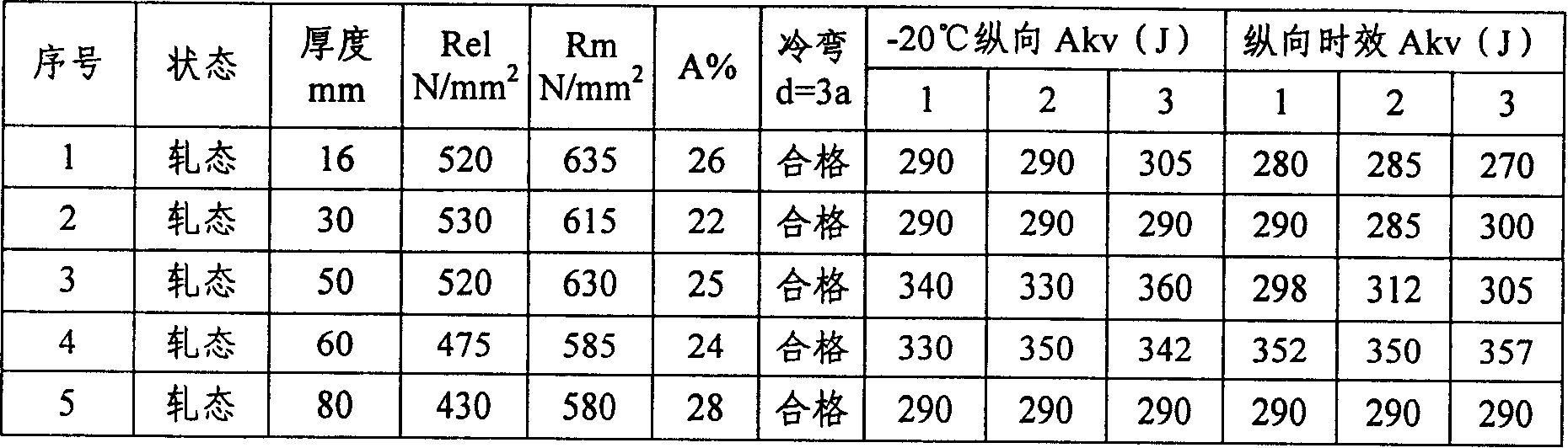

[0026] According to the designed chemical composition range of the present invention, 5 cans were smelted using the following smelting process. Its chemical composition is shown in Table 1, and its rolling process and as-rolled mechanical properties are shown in Tables 2 and 3.

[0027] It is smelted with a converter, blown by top blowing or combined top and bottom blowing; it is refined with LF and micro-alloyed; it is treated with Ca; continuous casting uses electromagnetic stirring.

[0028] The rolling process adopts TMCP+RPC process.

[0029] Table 1, the smelting composition example of the steel grade of the present invention, Wt%

[0030] serial number

C

Si

mn

als

Ni

Cr

Cu

Ti

Nb

Pcm

1

0.05

0.27

1.80

0.029

0.20

0.26

0.30

0.008

0.045

0.180

2

0.05

0.42

1.66

0.034

0.25

0.33

0.37

0.010

0.031 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com