High-quality garment machining process based on latching position difficult to shift

A processing technology and high-quality technology, applied in the field of garment processing, can solve problems such as slippage, affecting the quality of shirts, and position misalignment, etc., and achieve the possible effects of high work efficiency, improved quality, and reduced misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

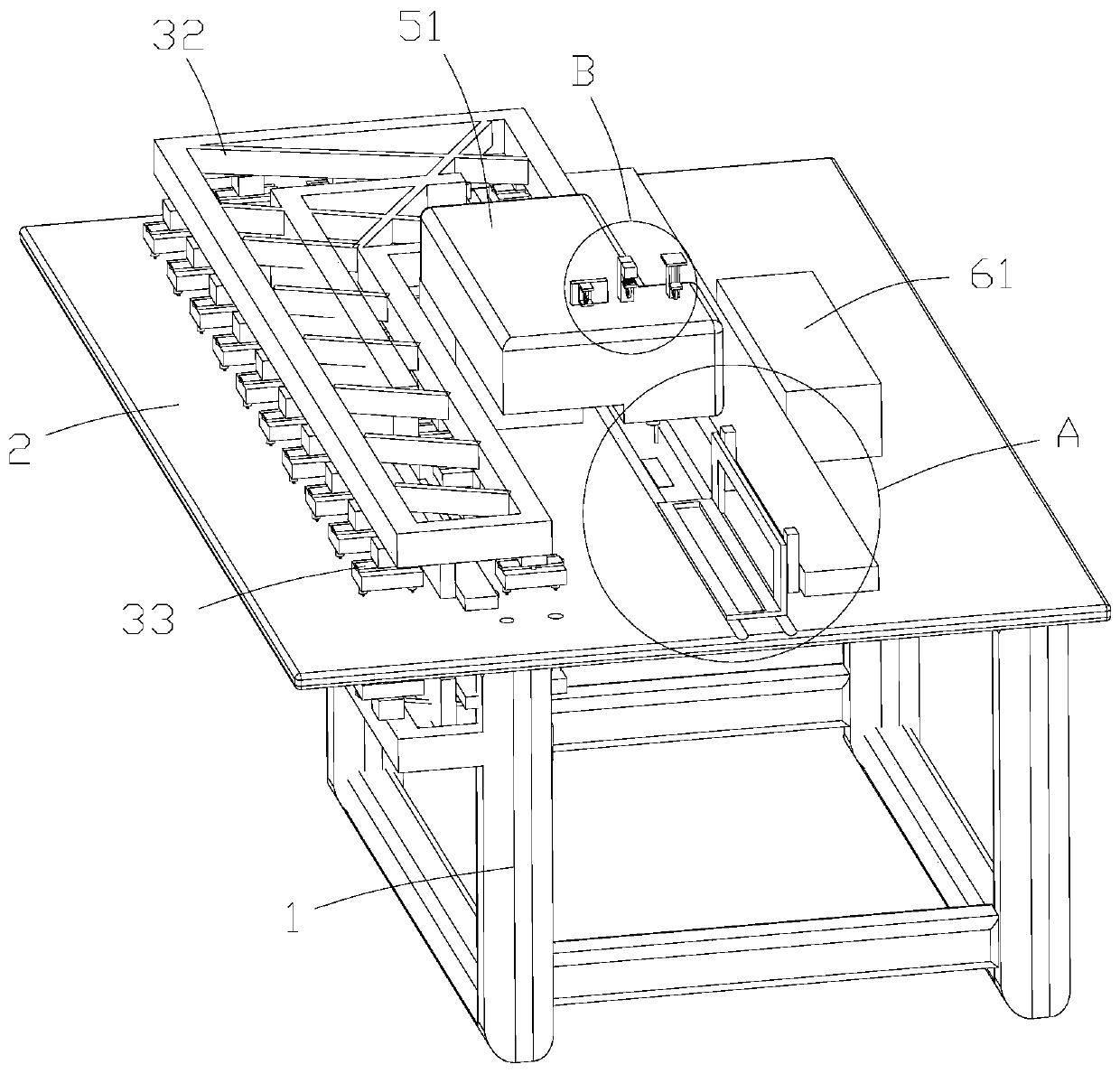

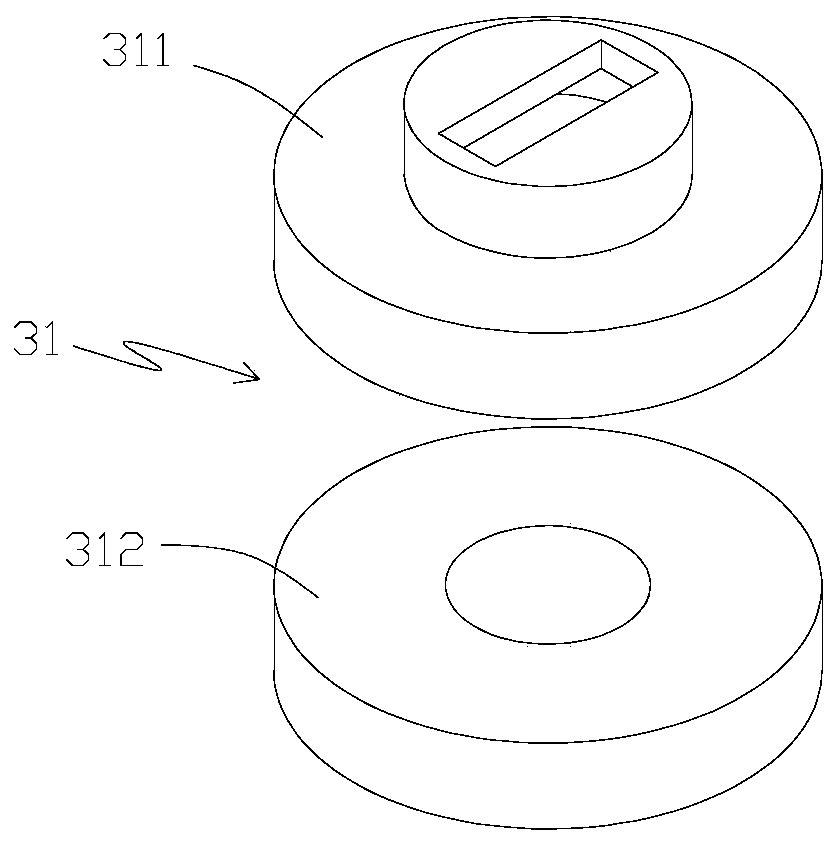

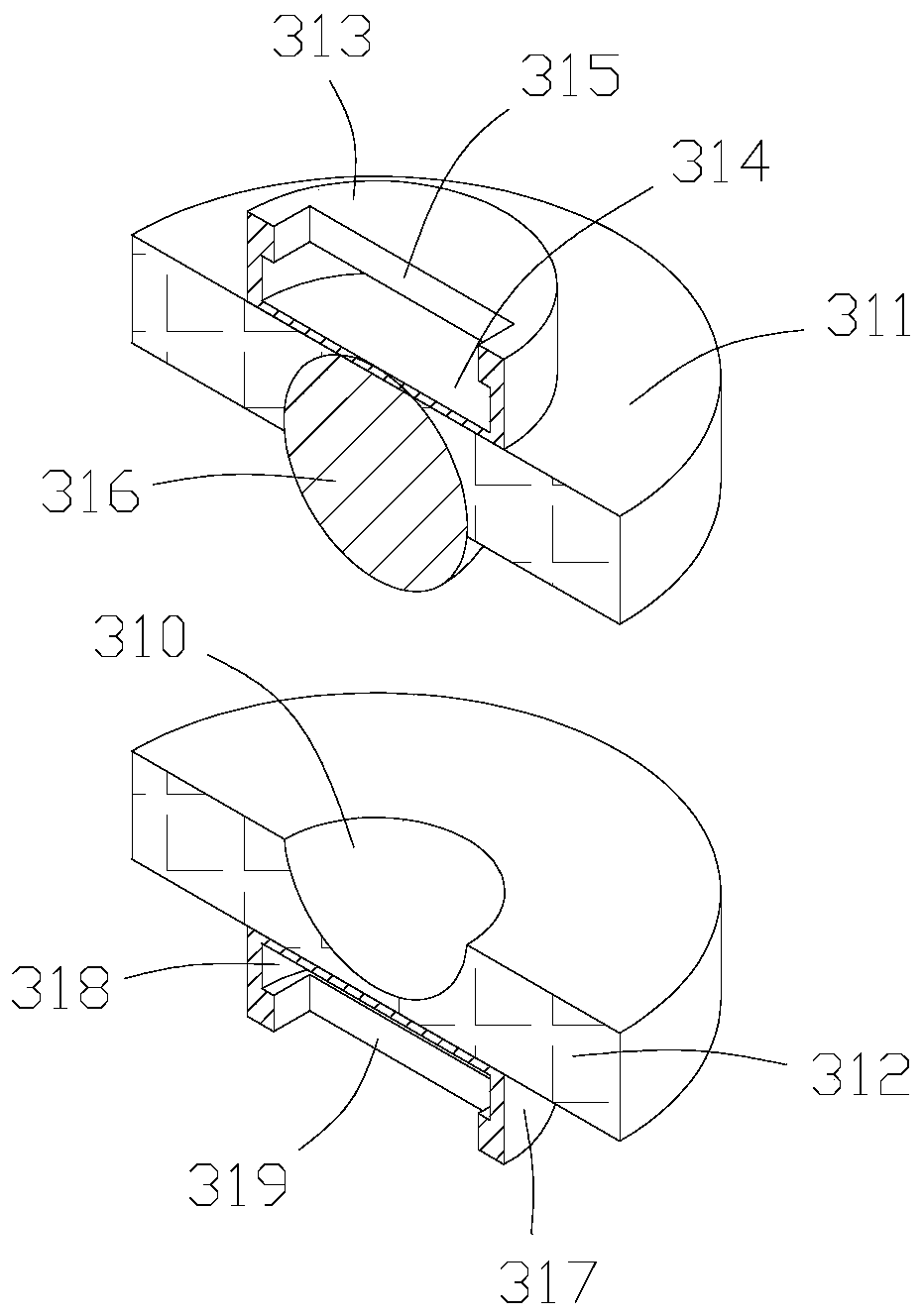

[0034] Such as Figure 1-9 As shown, a high-quality clothing processing technology based on the lock position is not easy to shift, including the following steps:

[0035] (1) Cutting: the fabric is cut by a cutting machine to obtain the basic fabric of the shirt;

[0036] (2) Sewing: use an automatic sewing machine to sew the basic fabric to obtain a semi-finished shirt;

[0037] (3) Locking: Use the locking device to lock the semi-finished shirts, and process the buttonholes on the shirts;

[0038] (4) Button sewing: use a button sewing machine to sew buttons on semi-finished shirts;

[0039] (5) Shaping: Shaping the semi-finished shirts obtained from the above processing at a temperature of 150°C;

[0040] (6) Collar pressing: After the finished shirt is pressed and circled, the finished shirt is obtained; the operation of pressing the collar is carried out at a temperature of 150°C; the operation of the collar is carried out at a temperature of 175°C ;

[0041] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com