Gas-liquid separator capable of being electrically heated

A gas-liquid separator, electric heating technology, applied in the separation method, dispersed particle separation, gas treatment, etc., can solve the problems of low temperature of electrolytic liquid, unfavorable rapid response of electrolyzed water hydrogen production equipment, etc., to achieve improved effect and integrated High degree of chemicalization and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The terms "first", "second" and the like in the description, embodiments, claims and drawings of the present invention are used to distinguish similar objects, and are not necessarily used to describe a specific sequence or sequence. Furthermore, the terms "comprising" and "having", as well as any variations thereof, are intended to cover a non-exclusive inclusion, for example, of a sequence of steps or elements. A method, system, product or device is not necessarily limited to those steps or elements explicitly listed, but may include other steps or elements not explicitly listed or inherent to the process, method, product or device.

[0019] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

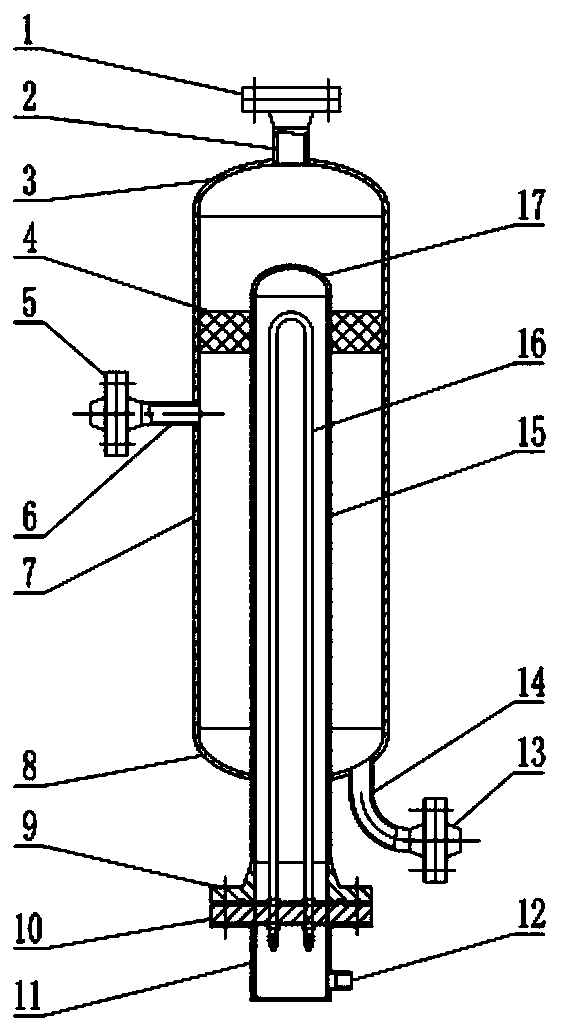

[0020] Such as figure 1 , an embodiment of the present invention provides an electrically heatable gas-liquid separator, including a heating component and a gas-liquid separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com