Degradable tissue clip injection mold and processing process

A technology of injection mold and tissue clip, applied in the field of tissue clip processing, can solve the problems of cumbersome processing process, and achieve the effect of simple processing process, shortening size, and ensuring continuous progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

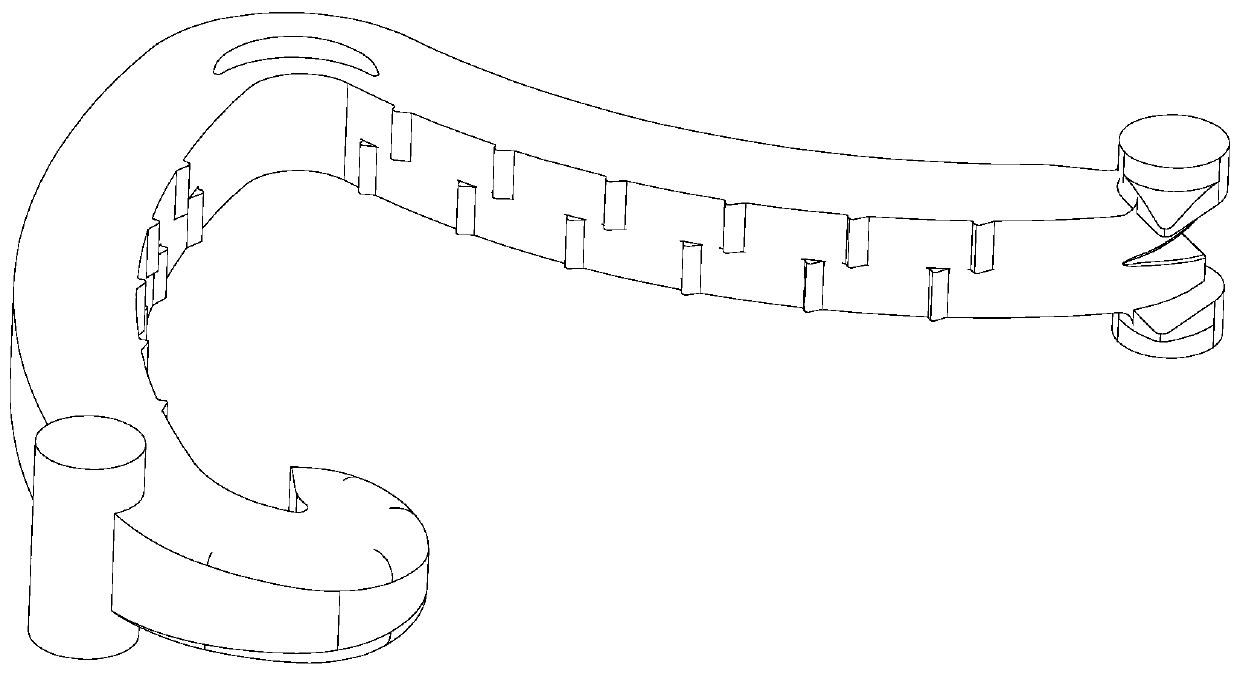

Image

Examples

Embodiment

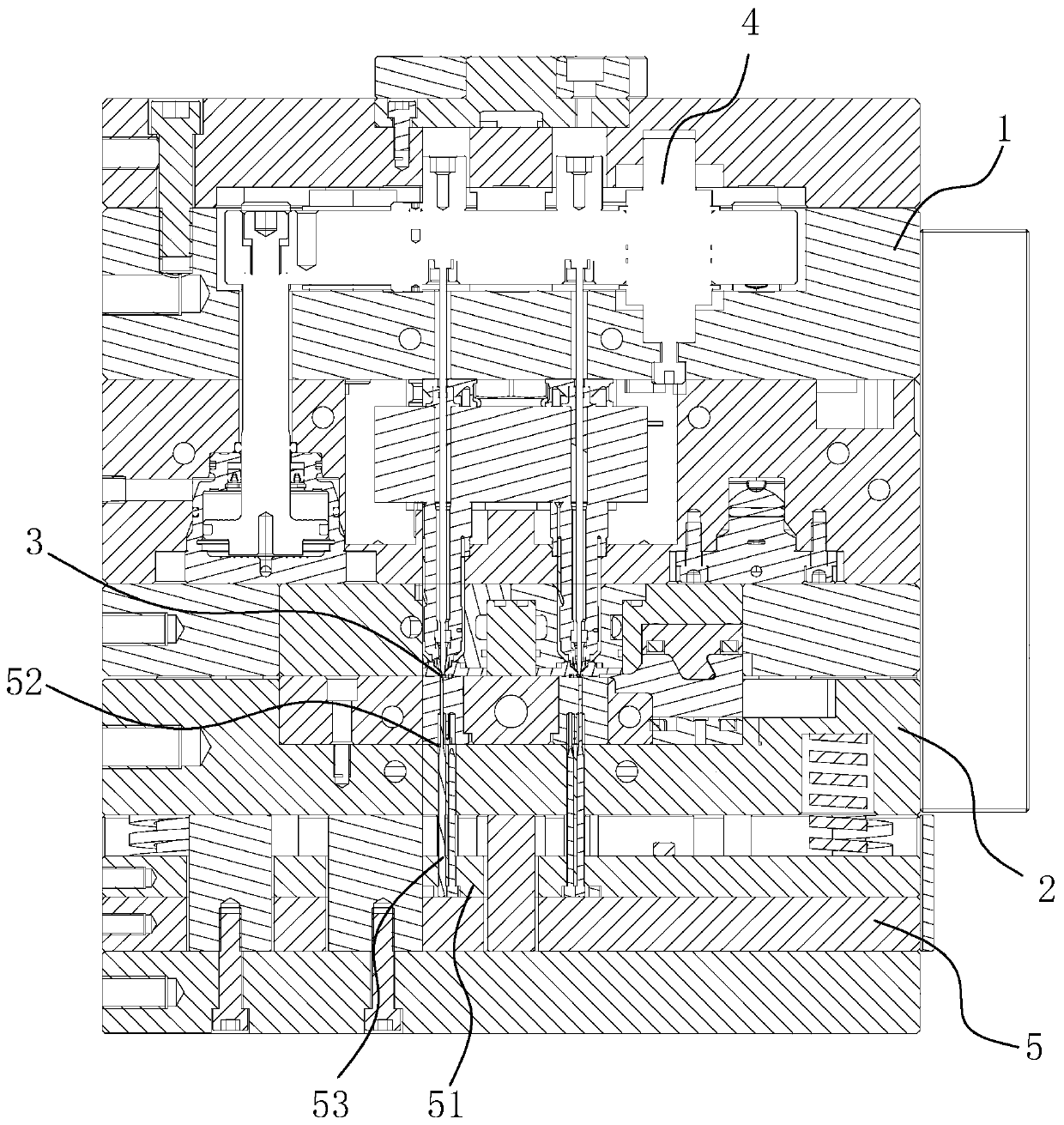

[0032] A degradable tissue clip injection mold, such as Figure 2 to Figure 3 As shown, it includes: an upper mold 1 and a lower mold 2, and several molding cavities 3 are arranged between the upper mold 1 and the lower mold 2; a hot runner injection molding system 4 arranged on the upper mold 1; and a demoulding mechanism 5.

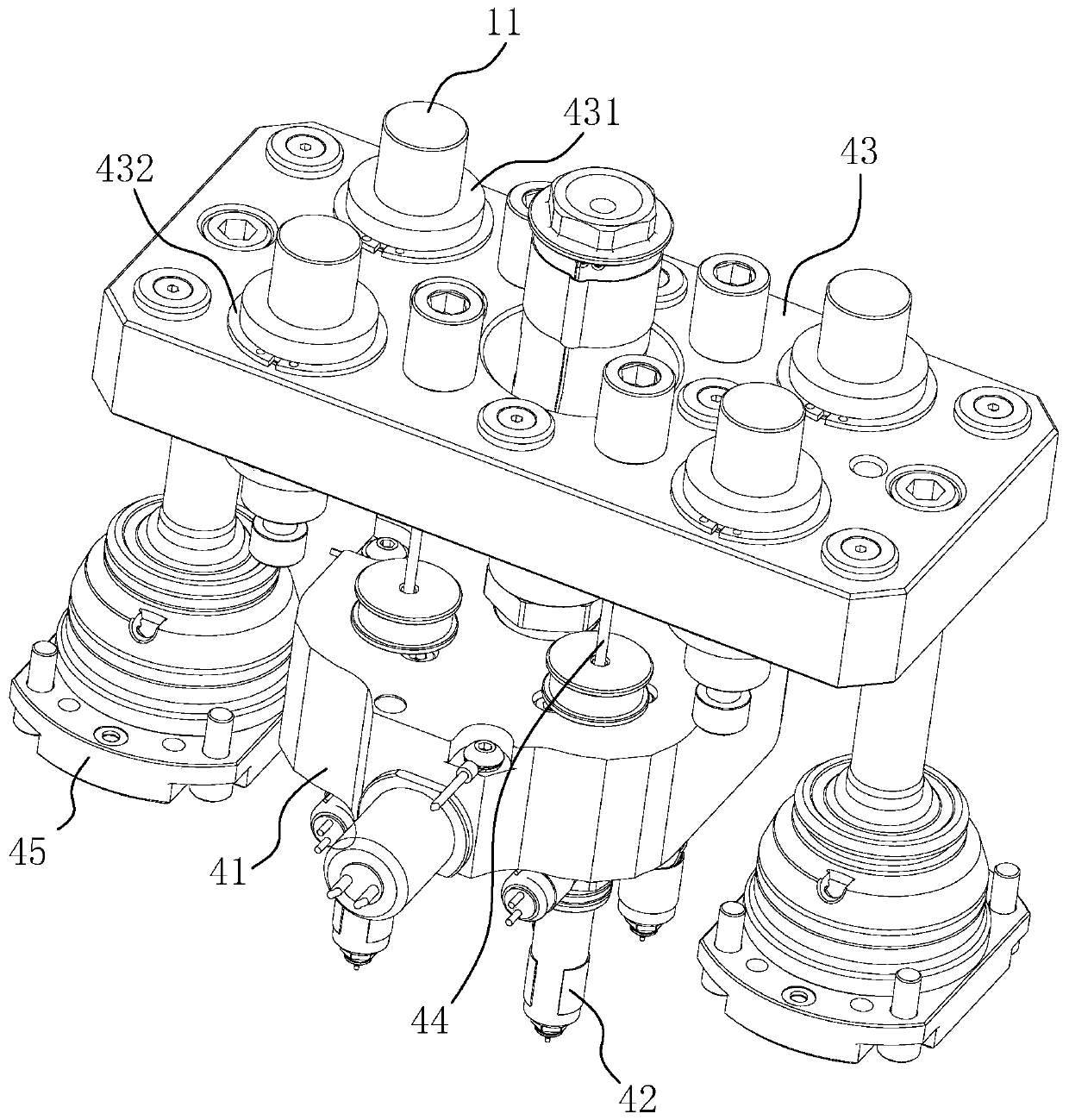

[0033] Specifically, the hot runner injection molding system 4 includes: a runner plate 41, a number of hot nozzles 42 connected to the runner plate 41 and matched with the molding cavity 3, a push plate 43 slidingly assembled on the upper mold 1, fixed on the The push plate 43 is used to open and close the valve needle 44 of the hot nozzle 42, and the driving cylinder 45 fixed on the upper mold 1 and connected to the push plate 43. The plastic capacity of the hot runner injection molding system 4 is less than that of the injection molding material and can be molded within the degradation time The difference between the injection volume of the machine a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com