Plate-and-frame filter press with filter plate convenient to replace

A plate and frame filter press and filter plate technology, applied in the direction of filtration separation, special treatment targets, water/sludge/sewage treatment, etc., can solve the problems of large filtering force, difficult replacement, and difficult removal, etc., to achieve convenient The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

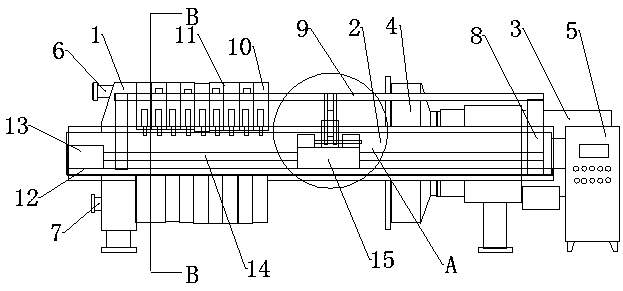

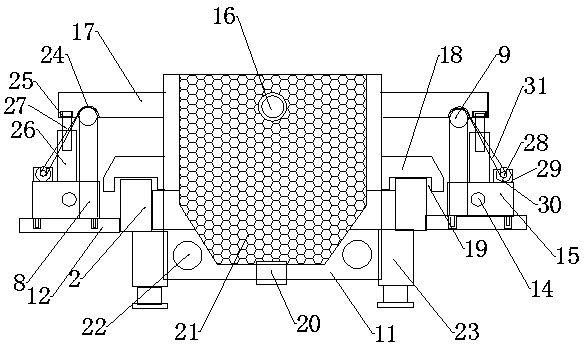

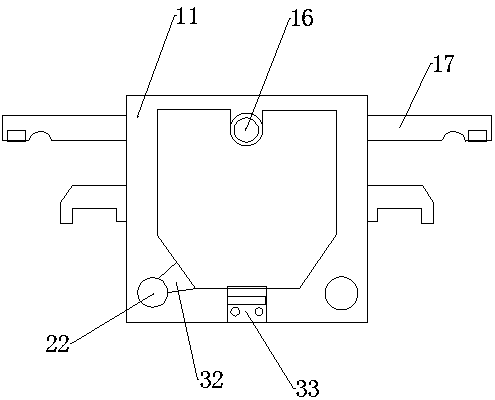

[0023] Such as Figure 1-5 As shown, a plate and frame filter press for easy replacement of filter plates includes a thrust plate 1, the front and rear of the thrust plate 1 are fixedly equipped with a main beam 2, the opposite side of the main beam 2 and An oil cylinder 3 is fixedly installed on the right end of the main beam 2, and the output end of the oil cylinder 3 is fixedly installed with a compression plate 4 that is movably connected with the two main beams 2. The front of the oil cylinder 3 is located on the right side of the main beam 2 A control box 5 is fixedly installed, and a feeding pipe 6 passing through the thrust plate 1 is fixedly installed on the left side of the thrust plate 1, and a There are two water outlet pipes 7 that run through the thrust plate 1, and the outer sides of the two main beams 2 are fixedly provided with support plates 12, and the left and right sides of the support plates 12 are provided with fixed columns 8. The top of the fixed colu...

Embodiment 2

[0026] Such as Figure 1-5 As shown, a plate and frame filter press for easy replacement of filter plates includes a thrust plate 1, the front and rear of the thrust plate 1 are fixedly equipped with a main beam 2, the opposite side of the main beam 2 and An oil cylinder 3 is fixedly installed on the right end of the main beam 2, and the output end of the oil cylinder 3 is fixedly installed with a compression plate 4 that is movably connected with the two main beams 2. The front of the oil cylinder 3 is located on the right side of the main beam 2 A control box 5 is fixedly installed, and a feeding pipe 6 passing through the thrust plate 1 is fixedly installed on the left side of the thrust plate 1, and a There are two water outlet pipes 7 that run through the thrust plate 1, and the outer sides of the two main beams 2 are fixedly provided with support plates 12, and the left and right sides of the support plates 12 are provided with fixed columns 8. The top of the fixed colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com