A jet pump for automatic uniform gas supply and corrosion reduction

A jet pump and uniform technology, applied in the field of jet pump, can solve the problems of hydraulic asymmetry of the throat, low feasibility, limited cavitation damage, avoid noise and severe vibration, ensure safe and stable operation, and promote high The effect of using value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

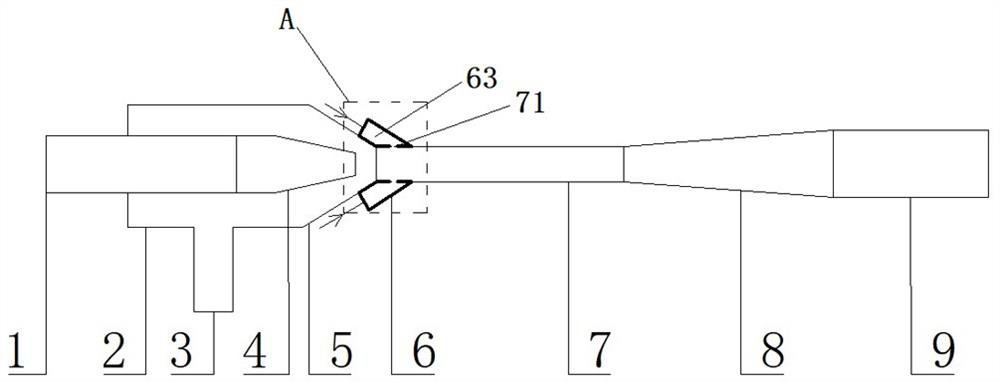

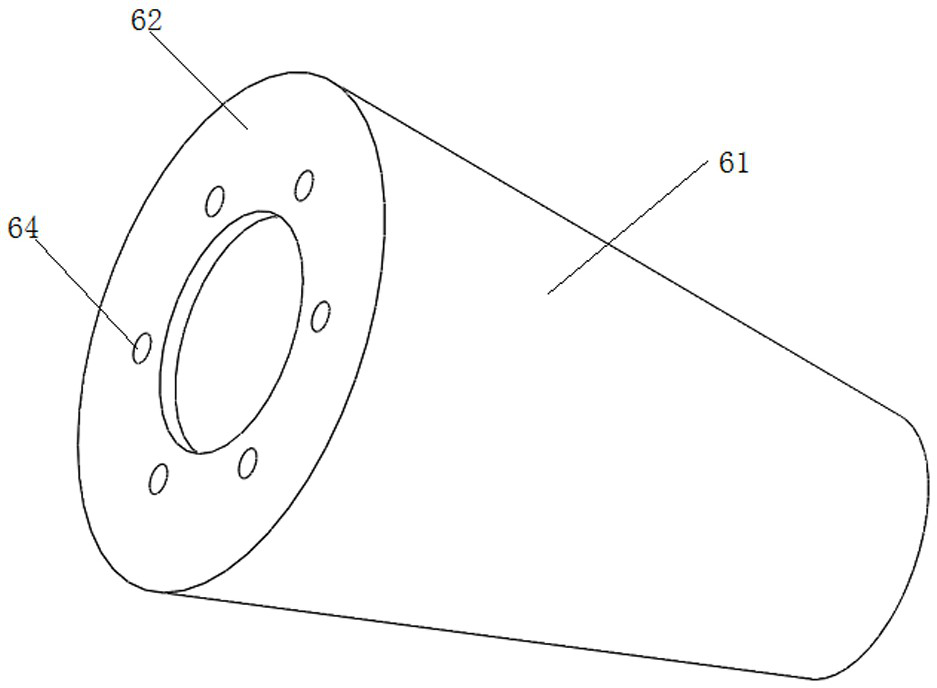

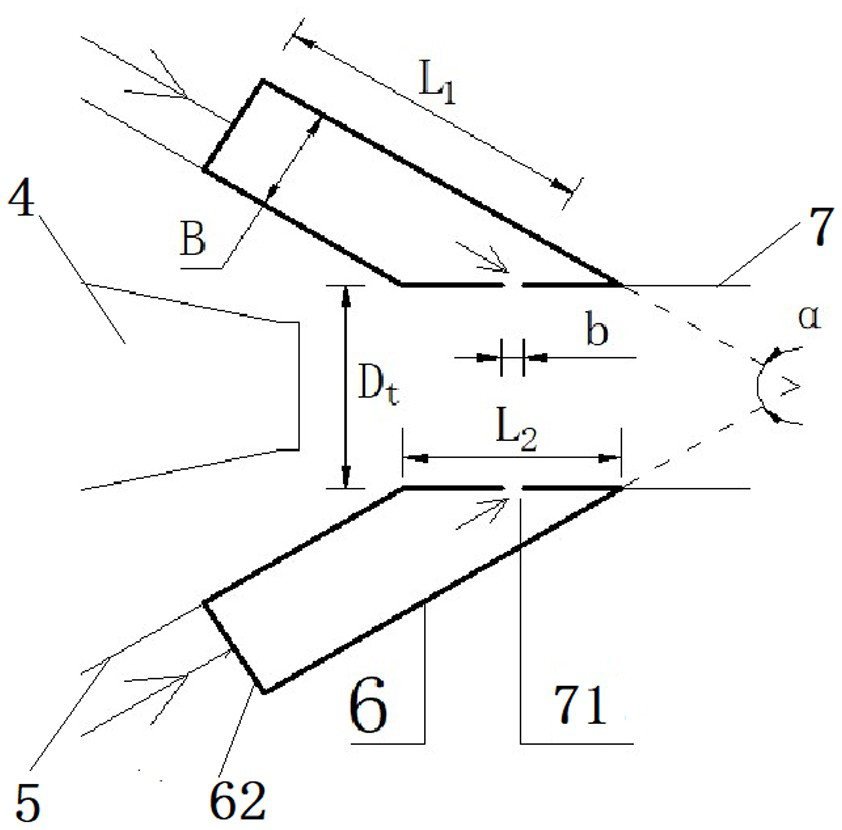

[0025] Such as figure 1 As shown, the jet pump in the prior art includes a water suction pipe 3 connected in sequence, a suction chamber 2, a throat inlet section 5, a throat pipe 7, a diffuser pipe 8 and a water outlet pipe 9, and a working water pipe 1 is inserted into the suction chamber 2 , one end of the working water pipe 1 is connected with a nozzle 4, and the nozzle 4 is arranged in the inlet section 5 of the throat pipe and facing the throat pipe 7. Such as Figure 1 to Figure 6 As shown, the present invention is a jet pump for automatically and uniformly supplying air and reducing corrosion, which adds a circumferential air equalizing groove 6 on the basis of the existing jet pump.

[0026] Such as Figure 1 to Figure 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com