Microwave vacuum pyrolysis method for combustible solid waste

A solid waste, microwave vacuum technology, applied in the combustion method, microwave heating, combustion type and other directions, can solve the problems of poor safety and deflagration, and achieve the effect of shortening the combustion time and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments.

[0023] A microwave vacuum pyrolysis method for combustible solid waste, comprising the steps of:

[0024] (1) Vacuum treatment of combustible solid waste to reach a state of negative pressure, and the degree of vacuum is kept at least -30KPa.

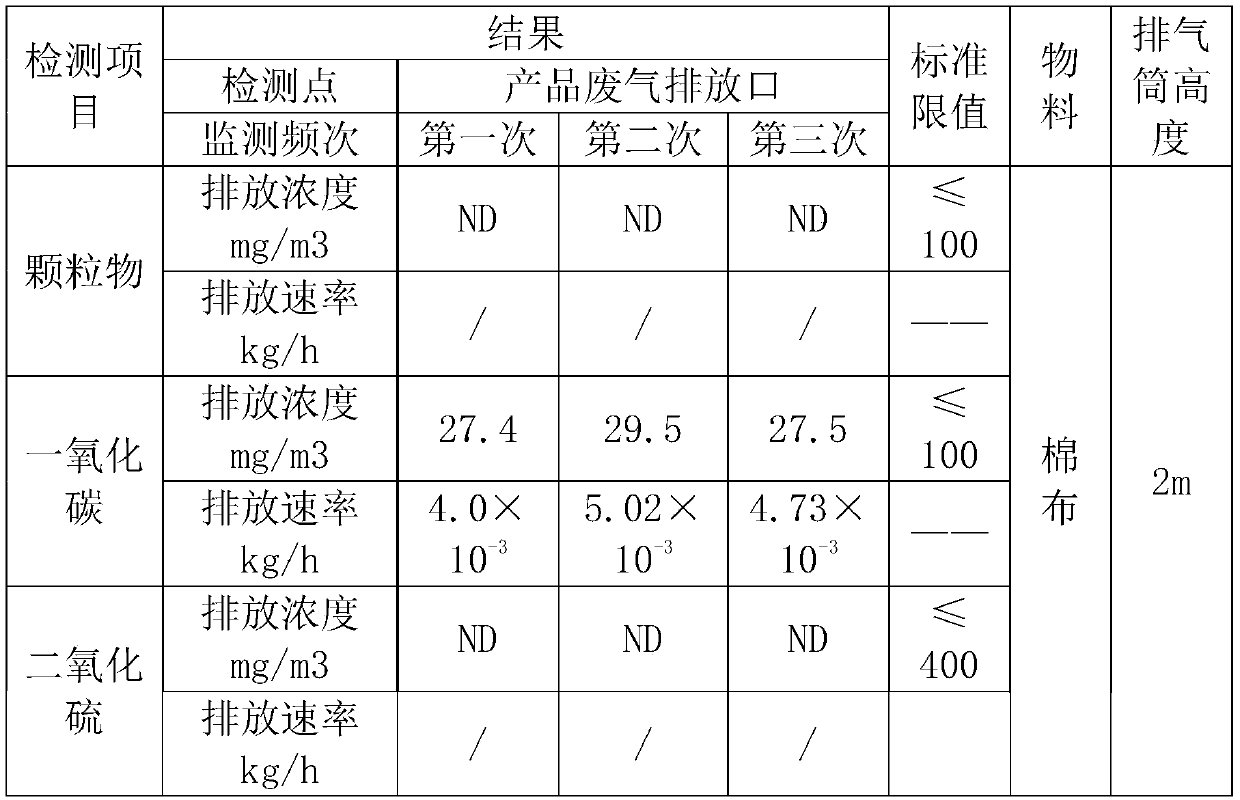

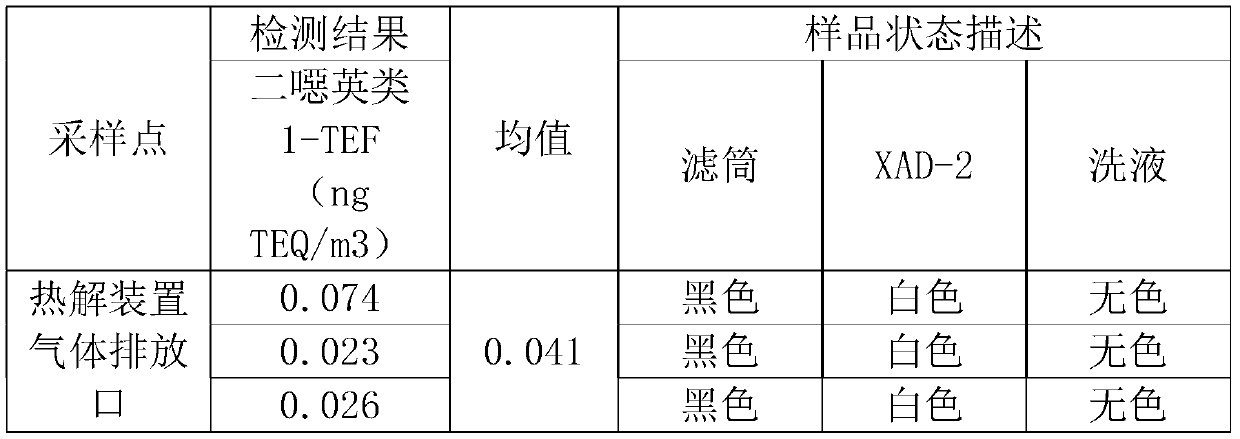

[0025] (2) Heating the combustible waste after vacuum treatment. The heating method adopts microwave heating to 580-640 ℃. During the heating process, the vacuum degree should always be maintained to reach -30KPa to -70KPa, and the gas generated by pyrolysis should be heated. It is extracted and discharged after being purified by the flue gas purification system; the heating time varies according to the weight of the combustible solid waste. The reference value is: the heating time of 2 kg of pure cotton cloth is 22 minutes.

[0026] (3) Stop heating, and the temperature of combustible solid waste will continue to rise. De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com