High-sensitivity piezoelectric air pressure sensor and preparation method thereof

An air pressure sensor and high-sensitivity technology, used in fluid pressure measurement, instruments, and fluid pressure measurement using piezoelectric devices. Flexibility and sensitivity, high piezoelectric coefficient, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

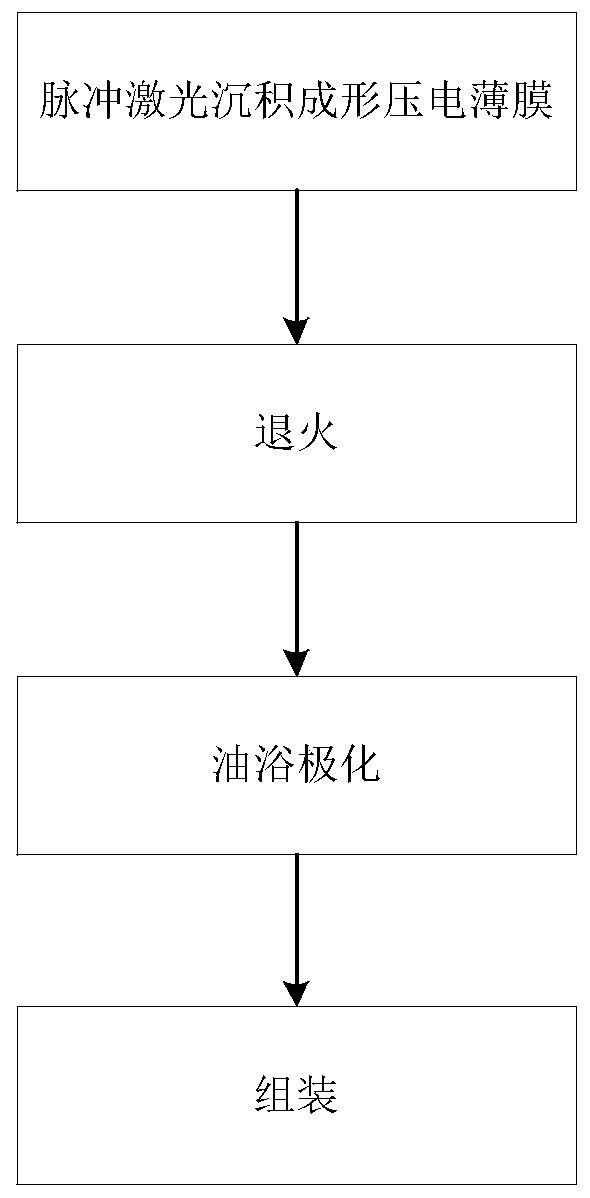

[0039] Such as figure 1 Shown, the preparation method of air pressure sensor in the present invention comprises the steps:

[0040] S1: Pretreat the target, surface grinding, polishing, and purging the surface with a nitrogen gun. In addition, the Mica mica substrate is manufactured and cleaned with ethanol and deionized water in a plasma cleaning agent. When finished, glue the Mica mica to the heating table using silver glue and dry it in a low-temperature dryer.

[0041] S2: Set the relevant parameters of the pulsed laser deposition equipment: pulse number 10000-50000 times, pulse frequency 5-10HZ, target-base distance 35-55mm, oxygen partial pressure 100-300mtorr, etc., start the equipment, and deposit nanoscale pressure on the surface of Mica. Electric thin film.

[0042] S3: Set the annealing temperature to 650-750°C, change the oxygen partial pressure to an atmospheric pressure of 760 torr, and hold the temperature for a certain time of 1-3 hours, and perform in-situ ...

Embodiment 1

[0053] S1: Pretreat the target, surface grinding, polishing, and purging the surface with a nitrogen gun. In addition, the Mica mica substrate is manufactured and cleaned with ethanol and deionized water in a plasma cleaning agent. When finished, glue the Mica mica to the heating table using silver glue and dry it in a low-temperature dryer.

[0054] S2: Set up the relevant parameters of the pulsed laser deposition equipment: pulse number 10000 times, pulse frequency 5HZ, target base distance 35mm, oxygen partial pressure 100mtorr, etc., start the equipment, and deposit nanoscale piezoelectric film on the surface of Mica.

[0055] S3: Set the annealing temperature to 650°C, change the oxygen partial pressure to an atmospheric pressure of 760 torr, and hold the temperature for a certain time for 3 hours, and perform in-situ annealing on the film at a certain cooling rate of 5°C / min.

[0056] S4: For a piezoelectric film with better quality, stick a mask, and use evaporation eq...

Embodiment 2

[0060] S1: Pretreat the target, surface grinding, polishing, and purging the surface with a nitrogen gun. In addition, the Mica mica substrate is manufactured and cleaned with ethanol and deionized water in a plasma cleaning agent. When finished, glue the Mica mica to the heating table using silver glue and dry it in a low-temperature dryer.

[0061] S2: Set up the relevant parameters of the pulse laser deposition equipment: pulse number 10000 times, pulse frequency 5HZ, target base distance 55mm, oxygen partial pressure 300mtorr, etc., start the equipment, and deposit nanoscale piezoelectric film on the surface of Mica.

[0062] S3: Set the annealing temperature to 750°C, change the oxygen partial pressure to an atmospheric pressure of 760 torr, and hold the temperature for a certain time for 3 hours, and perform in-situ annealing on the film at a certain cooling rate of 15°C / min.

[0063] S4: For a piezoelectric film with better quality, stick a mask, and use evaporation eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap