Macrobend loss testing device for optical fiber automatic winding counting and test nethod thereof

A technology of winding device and testing device, which is used in measurement devices, optical instrument testing, and testing of machine/structural components, etc., can solve the problems of non-adjustable fiber spacing, difficult adjustment, affecting test results, etc., to improve accuracy and applicability. Wide range of effects for easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

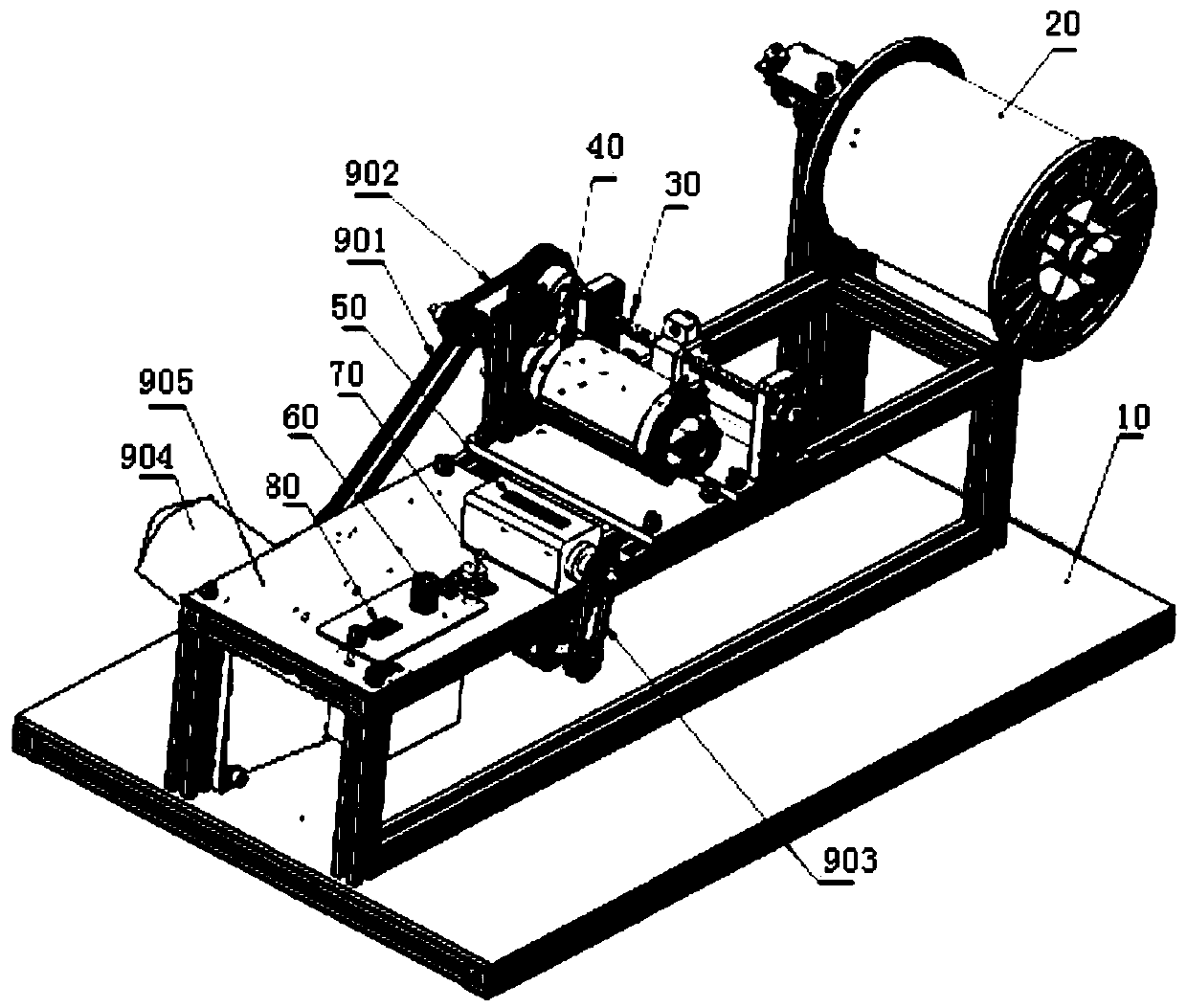

[0036] refer to figure 1 As shown, this embodiment discloses a macrobending loss testing device for optical fiber automatic winding counting, including a frame 10, an optical fiber reel pay-off device 20, a cable arrangement device 30, an optical fiber winding device 40, a counter 50 and a motor. The frame 10 is located below the entire device to support the entire winding device. The optical fiber reel pay-off device 20, the cable arrangement device 30, and the optical fiber winding device 40 are sequentially arranged on the frame. The optical fiber reel pay-off device 20 (the pay-off device is provided with a tensioning device, the purpose is to adjust the fiber optic reel pay-off tension or pay-off speed, and this device is applicable to large and small optical fiber reels) is located on the left side of the frame 10, and the cable arrangement device 20 has a wire The fiber guide hole 301 is set on the screw rod, and the optical fiber emitted by the fiber reel pay-off devic...

Embodiment 2

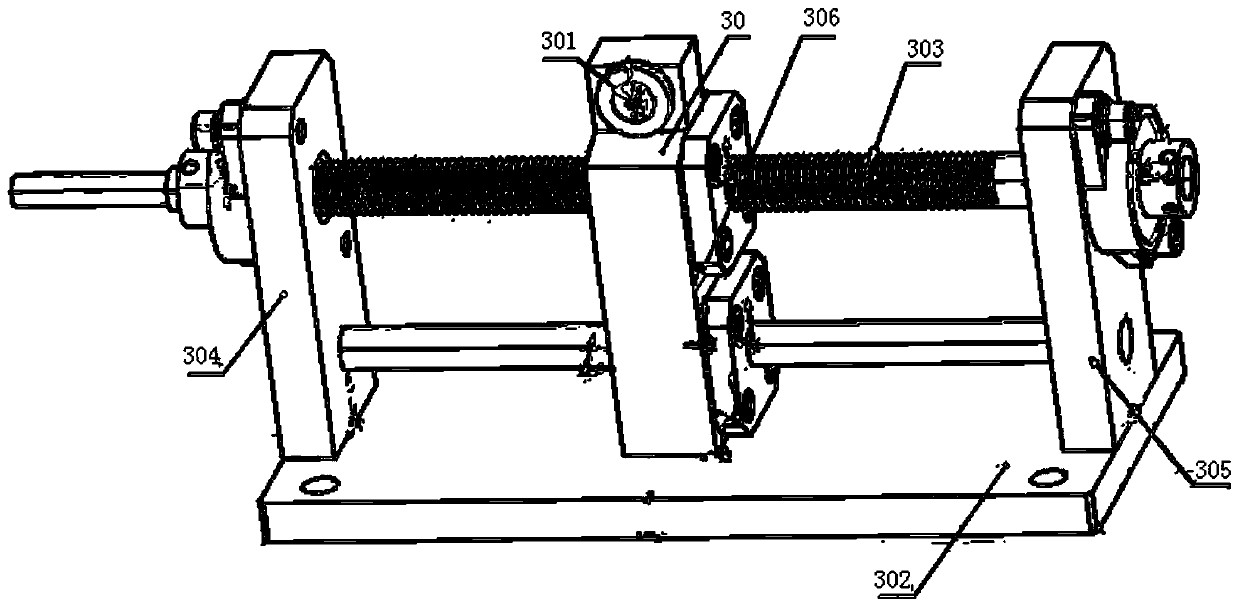

[0041] On the basis of Embodiment 1, the above-mentioned cable arranging device 30 includes: the above-mentioned cable arranging device bottom plate 302 , and the above-mentioned cable arranging device bottom plate 302 is used to support the above-mentioned cable arranging device 30 . The first support 304 of the cable arrangement device and the second support 305 of the cable arrangement device are arranged on both sides of the bottom plate 302 of the cable arrangement device. The part between the first support 304 of the above-mentioned cable arrangement device and the second support 305 of the above-mentioned cable arrangement device is also provided with the third support 306 of the above-mentioned cable arrangement device, and the top of the third support 306 of the above-mentioned cable arrangement device is equipped with a fiber guide hole 301, the fiber guide hole 301 is made of brass, the first function of the fiber guide hole is to protect the optical fiber, and the s...

Embodiment 3

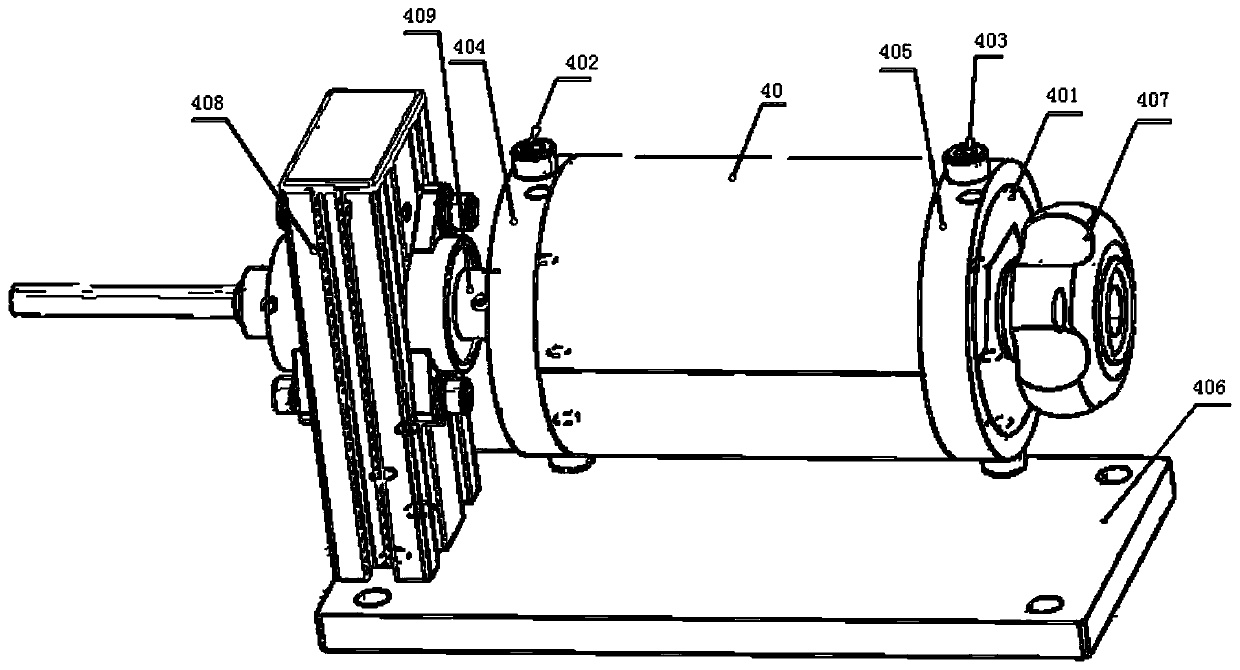

[0044] On the basis of Embodiment 1, the optical fiber winding device 40 includes: a bottom plate 406 of the optical fiber winding device, and the bottom plate 406 of the optical fiber winding device is used to support the optical fiber winding device 40 . The optical fiber winding device base plate 406 left side is provided with the optical fiber winding device support 408, and the optical fiber winding device support 408 is provided with the fixed-diameter shaft support shaft 409 that is placed parallel to the optical fiber winding device base plate 406, and the above-mentioned fixed-diameter shaft support shaft 409 is used to support the above-mentioned The fixed diameter shaft 401 of the optical fiber winder 40 is fixed by the fixed diameter shaft locking device 407 . Half of the fixed diameter shaft 401 is fixed, and the other half of the fixed diameter shaft 401 is loose, the interface between the fixed part and the loose part is parallel to the axial direction, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com