A double-inlet and double-outlet coal mill output measurement optimization method, system and medium

A technology of double input and double output, optimization method, applied in design optimization/simulation, volume measurement instrument/method, weighing, etc., can solve combustion control disturbance, inaccurate coal measurement, reduce unit economy and safety, etc. problems, to achieve the effects of accurate measurement, compensation of measurement distortion, improvement of automatic adjustment quality and economic level of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

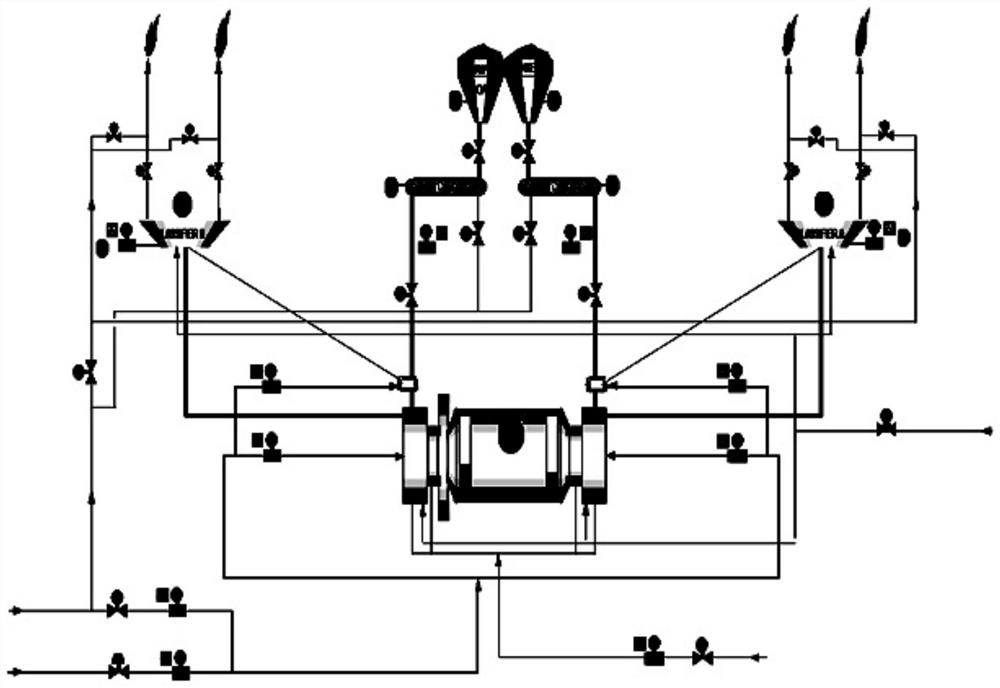

[0037] The following will be figure 1 The shown double-inlet and double-outlet coal mill is taken as an example, and the method, system and medium for output measurement optimization of the double-inlet and double-outlet coal mill of the present invention will be further described in detail. see figure 1 It can be seen that each double-inlet and double-outlet coal mill has two powder pipes, and each powder pipe corresponds to two burners. It should be noted that the output metering optimization method, system and medium of the double-inlet and double-outlet coal mill of the present invention are not limited to figure 1 The shown double-inlet and double-outlet coal mill can also be applied to a double-inlet and double-outlet coal mill with more powder pipes and more burners in each powder pipe.

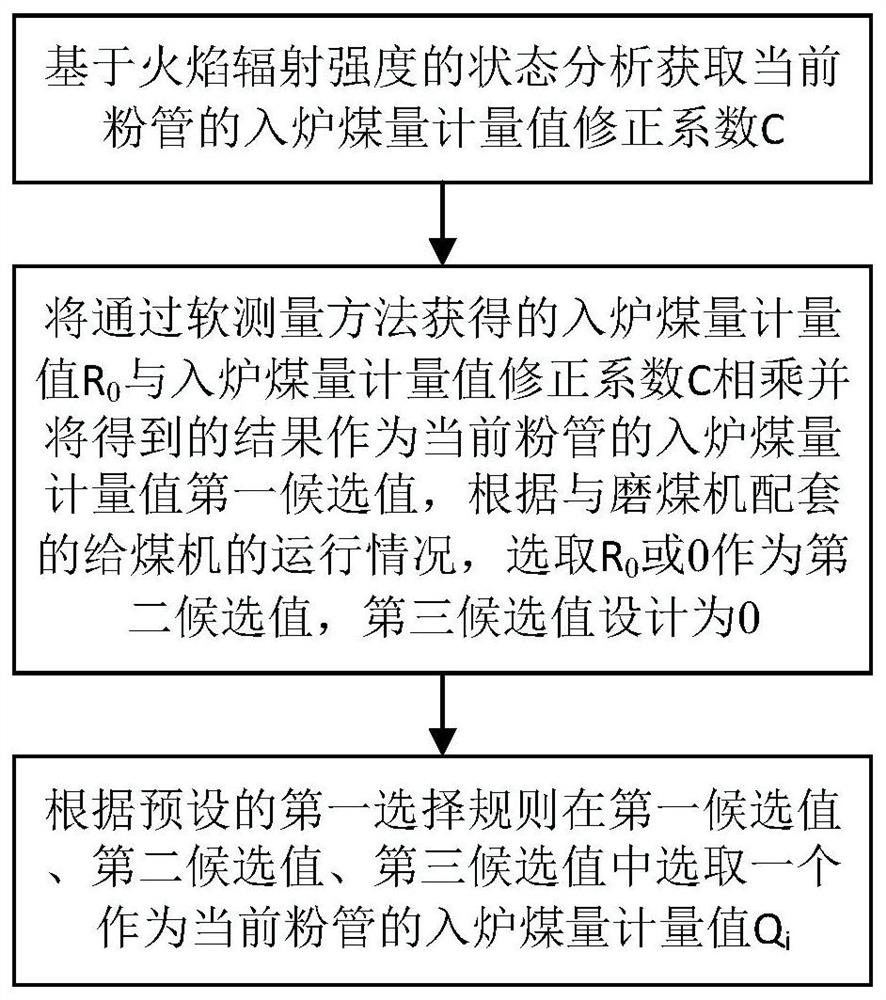

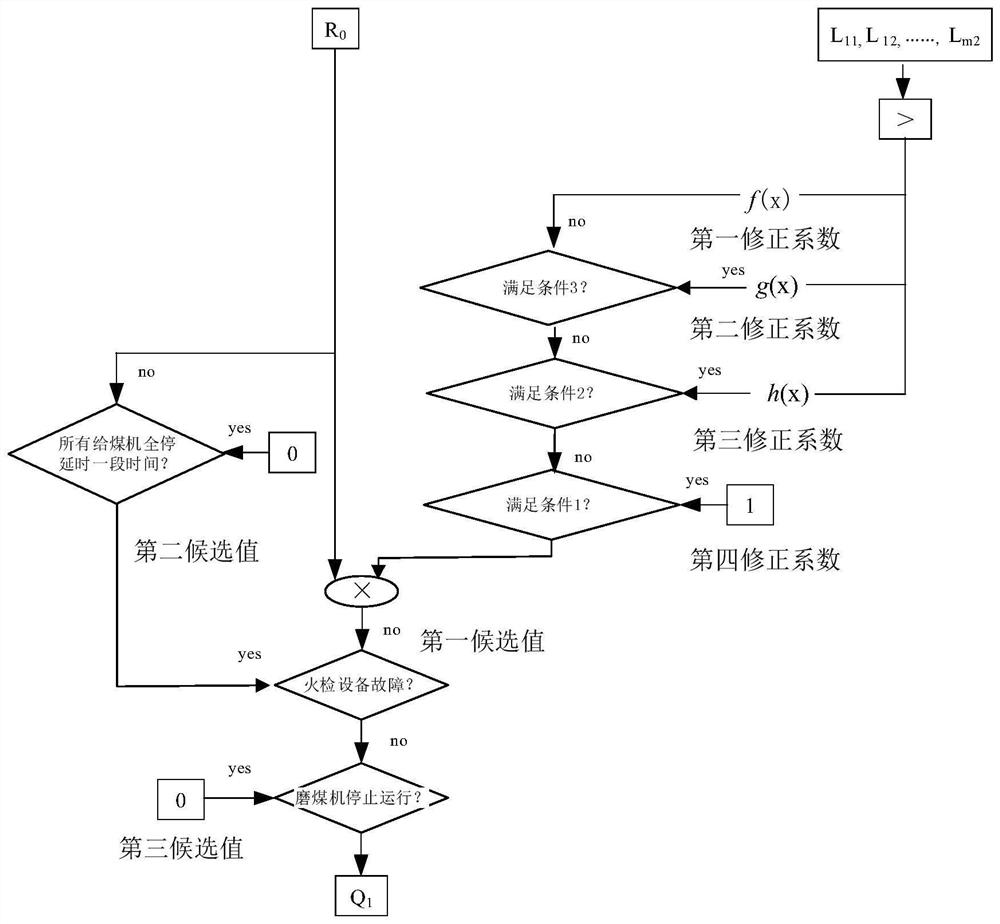

[0038] Such as figure 2 and image 3 As shown, the output measurement optimization method of the double-inlet and double-outlet coal mill in this embodiment includes calculating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com