Battery pole piece processing technology

A processing technology and battery pole piece technology, applied in the direction of battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of slow dust removal speed, low efficiency, and burrs that cannot fall off, etc., and achieve the effect of fast powder brushing speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

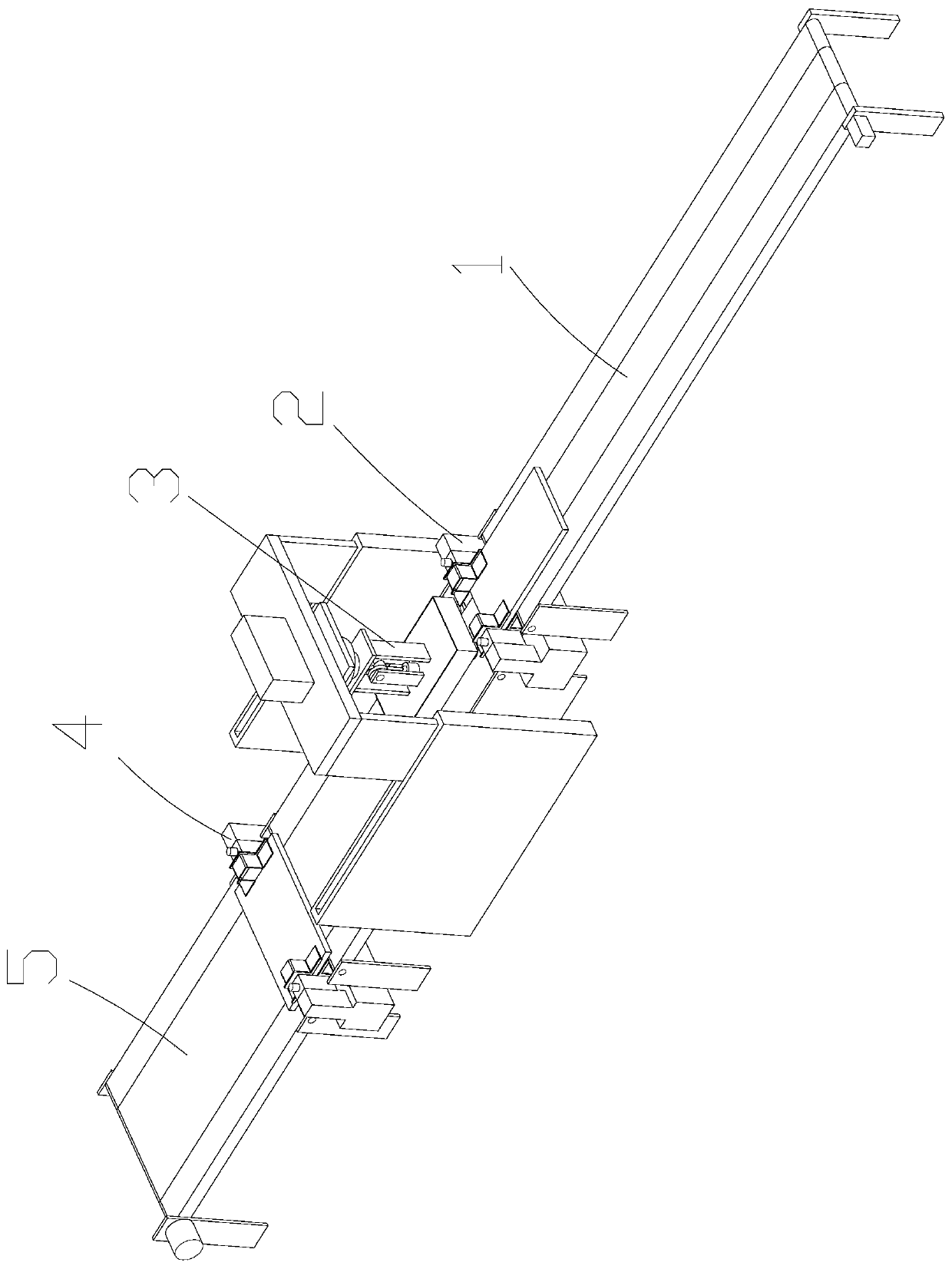

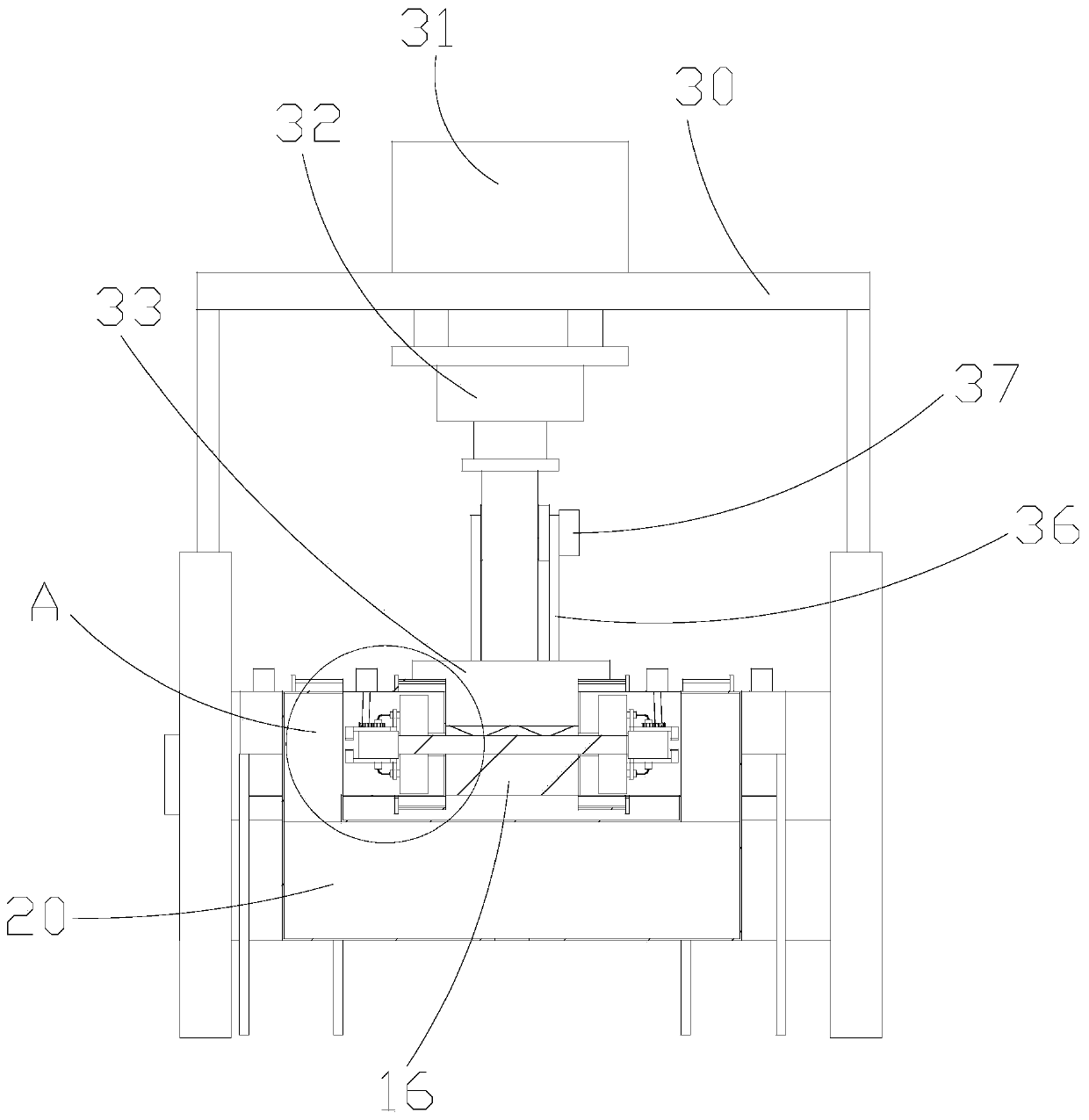

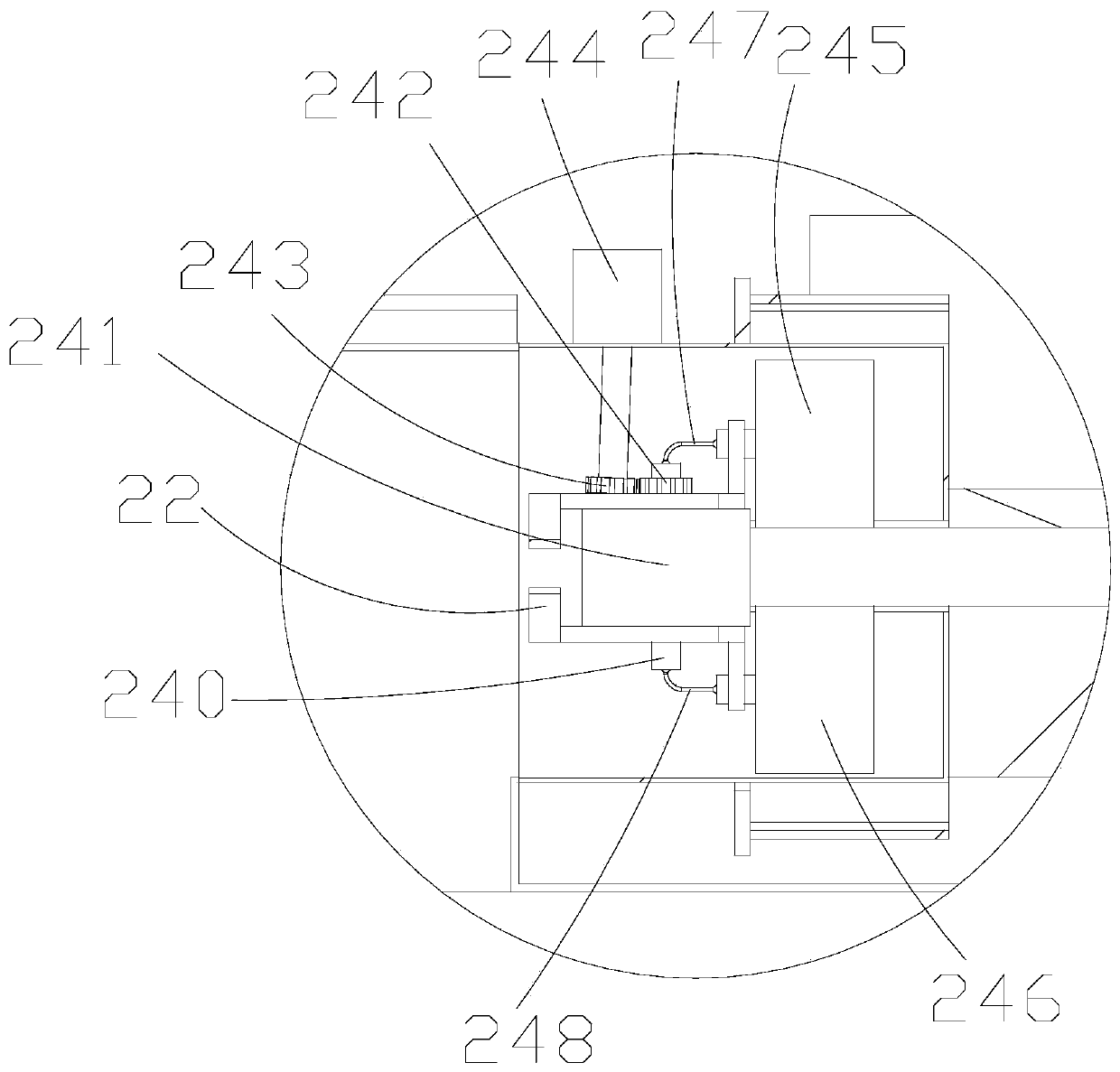

[0028] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0029] A battery pole piece processing technology, comprising the following steps:

[0030] a. Slurry preparation: the slurry is stirred by a stirring device, and the slurry is evenly dispersed;

[0031] b. Coating: Coating the prepared slurry on the front and back of the current collector metal foil through the coating equipment, and the coating on the front and back of the pole piece is symmetrical;

[0032] c. Drying: use a drying device to dry the coated pole piece to obtain a dried electrode structure;

[0033] d. Rolling: After the pole pieces are dried, they are rolled and compacted by a roller press;

[0034] e. Slitting: Use a slitting device to cut the rolled pole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com