High-heat-flux electronic component constant-temperature liquid cooling plate

A technology of high heat flux density and electronic components, applied in electrical components, circuits, secondary batteries, etc., can solve the problems of easy leakage of welding seam, corrosion leakage, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

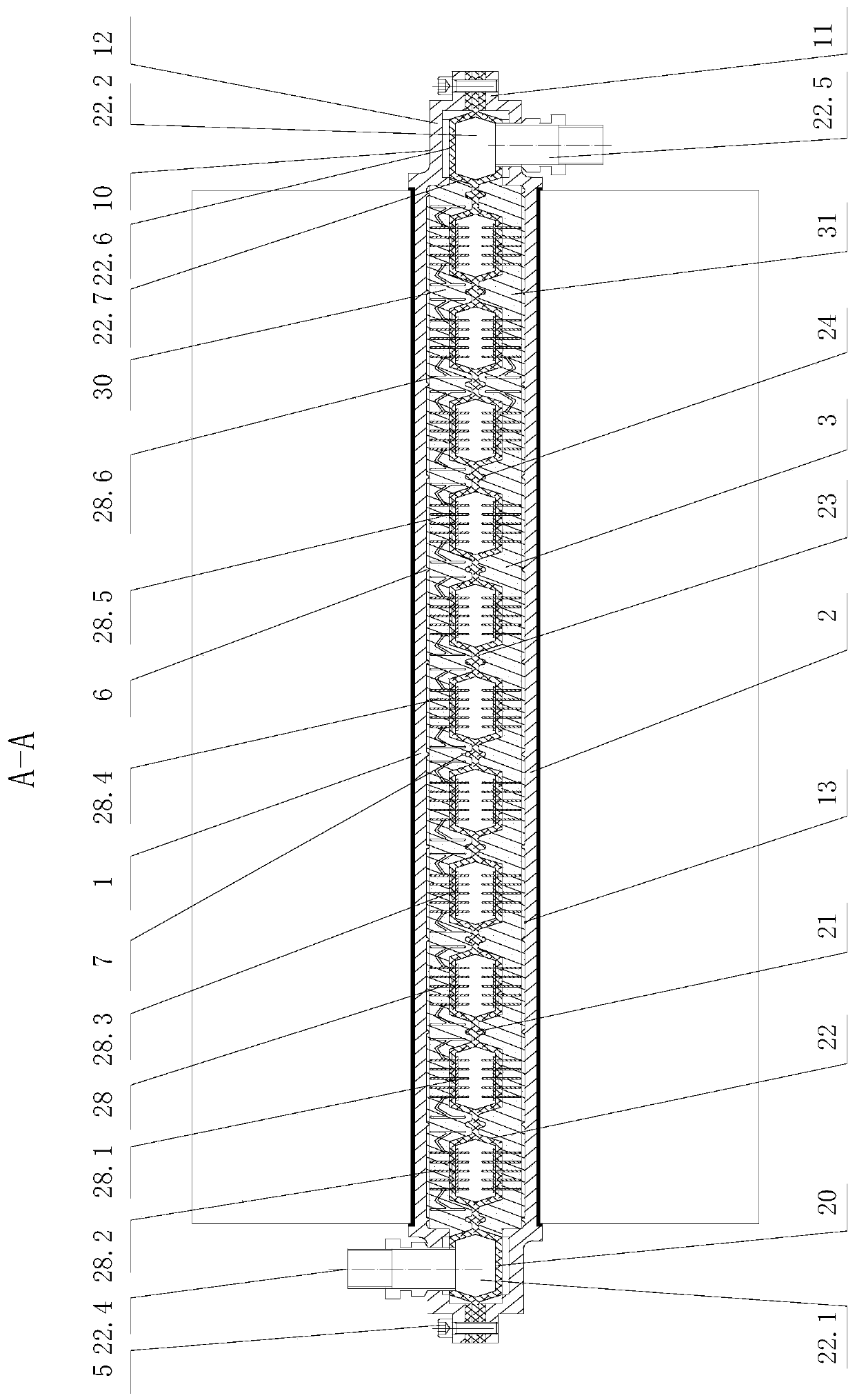

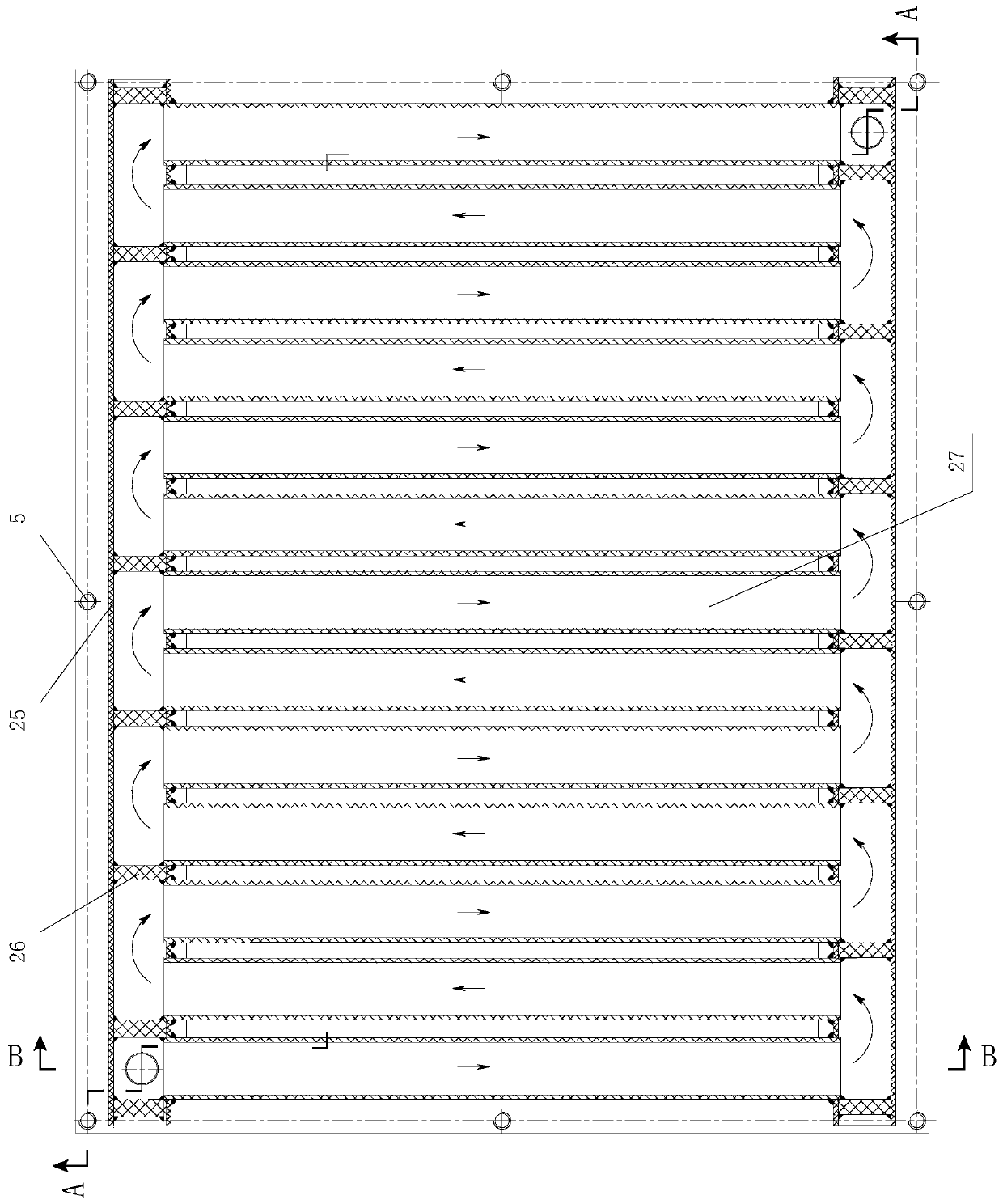

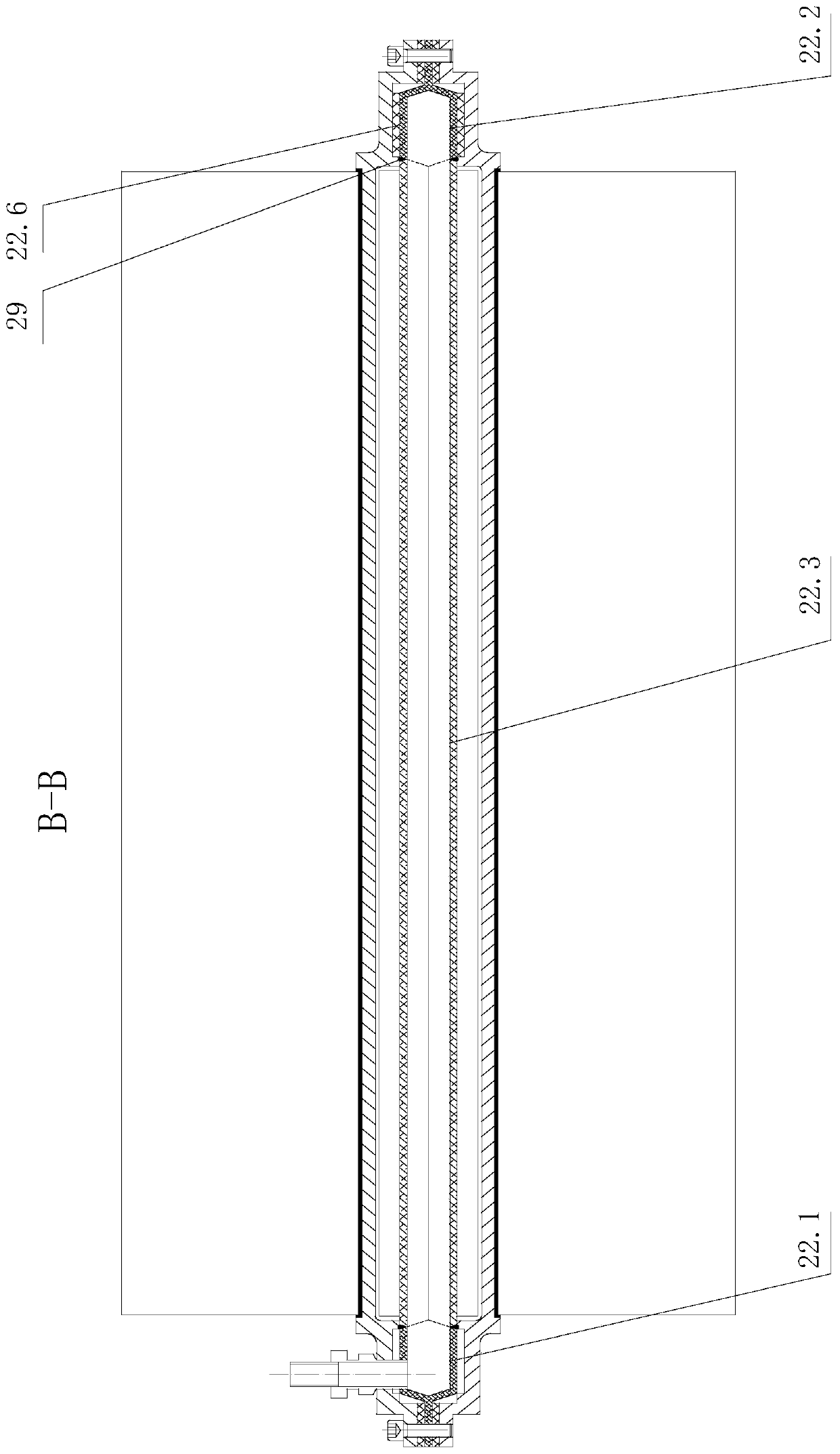

[0044] Such as Figure 1-3 As shown, a high heat flux constant temperature liquid cold plate for electronic components includes an upper cold plate 1, a liquid cooling mechanism 20 and a lower cold plate 2 stacked in sequence, and the upper cold plate 1 and the lower cold plate 2 respectively have a buckle sealing mechanism 10 The buckle sealing mechanism 10 includes a buckle flange part 11, a pressure flange part 12 and a concave cavity 13, and the upper cold plate 1 and the lower cold plate 2 are fastened to the liquid cooling mechanism through the buckle flange part 11 and the sealing ring respectively. 20 and tightened by the compression bolt 5, the pressure flange part 12 is pressed against the liquid cooling mechanism 20 through the sealing ring, so that the concave cavity of the upper cold plate and the concave cavity of the lower cold plate are combined to form a liquid-cooled The constant temperature chamber 3 on both sides of the mechanism 20 is provided with a solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com