Device for removing burrs of wheel bolt holes

A technology for removing burrs and bolt holes, which is applied in the field of deburring after wheel machining, and in the field of mechanical processing, which can solve the problems of low precision and low burr removal efficiency, and achieve the effects of high removal precision, flexible and convenient adjustment, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

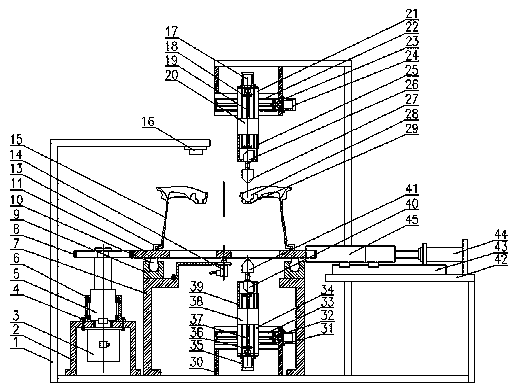

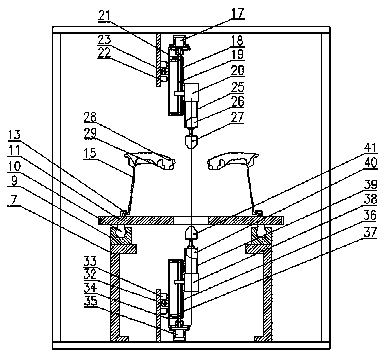

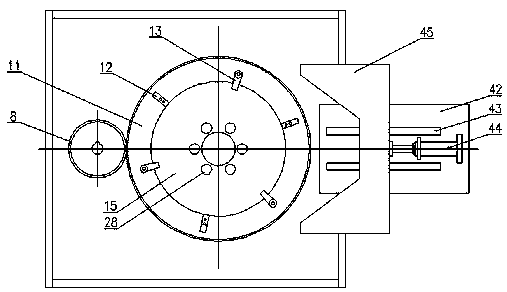

[0022] The following is attached with the manual Figure 1-3 Description Embodiment 1 of this application, a device for removing burrs from wheel bolt holes, including a wheel positioning and rotating system, an auxiliary clamping system, and a deburring system; the wheel positioning and rotating system is used for positioning and clamping and fixing wheels, and drives The wheel rotates according to the set angle; the auxiliary clamping system is used to clamp the wheel after the wheel is rotated in place according to the set angle to prevent the wheel from rotating; the deburring system includes two deburring units, which are used to lock the wheel The burr in the bolt hole and the burr on the back of the bolt hole are removed. The deburring unit includes a horizontal movement assembly, a vertical movement assembly, and a deburring assembly. The horizontal movement assembly can drive the vertical movement assembly to move horizontally. The vertical movement assembly can drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com