Machining device for wooden tea tray

A processing device and tea tray technology, which is applied to wood processing utensils, trays, manufacturing tools, etc., can solve the problems of broken tea trays, low efficiency, time-consuming and laborious, and achieve the effect of improving work efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

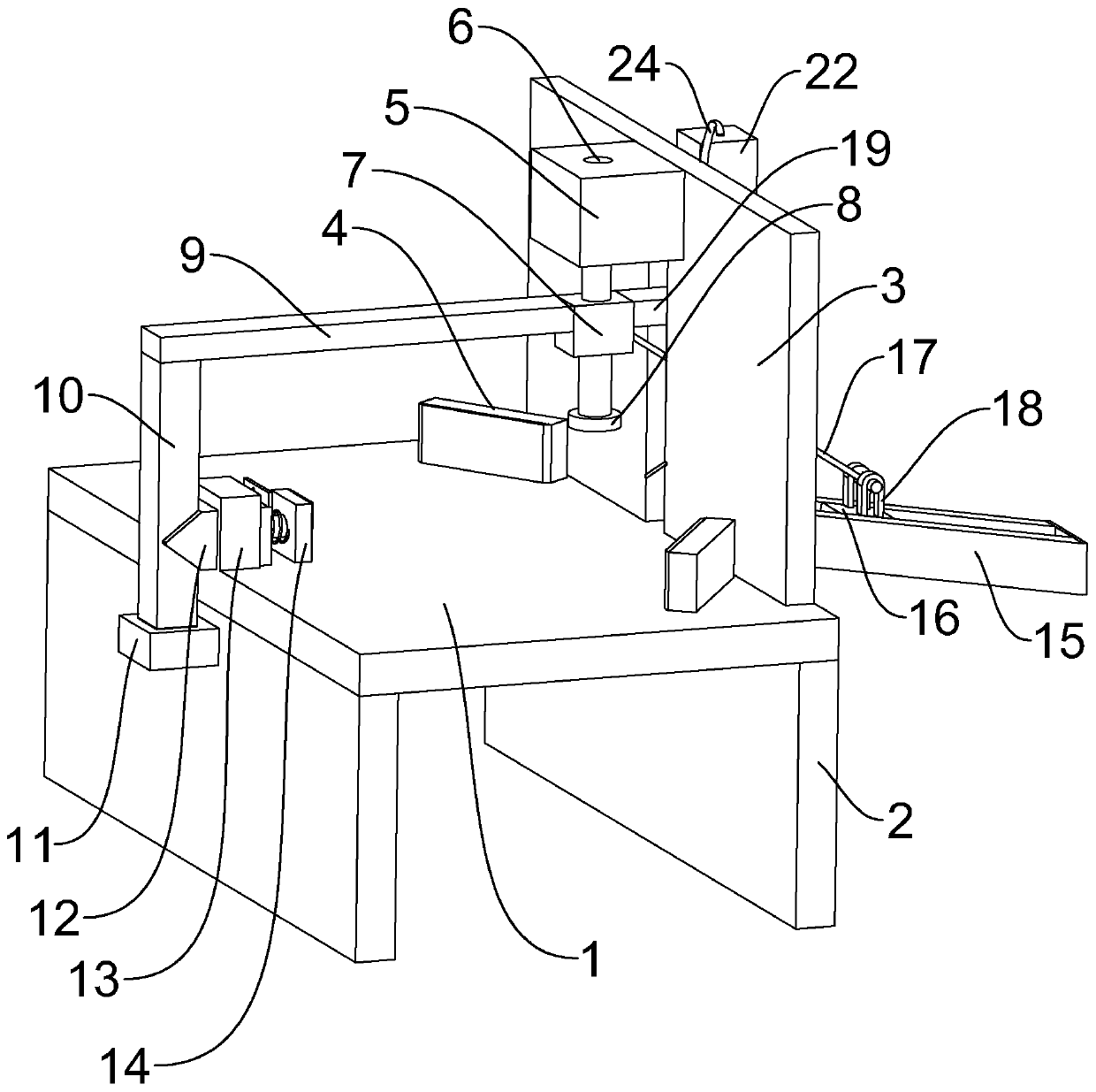

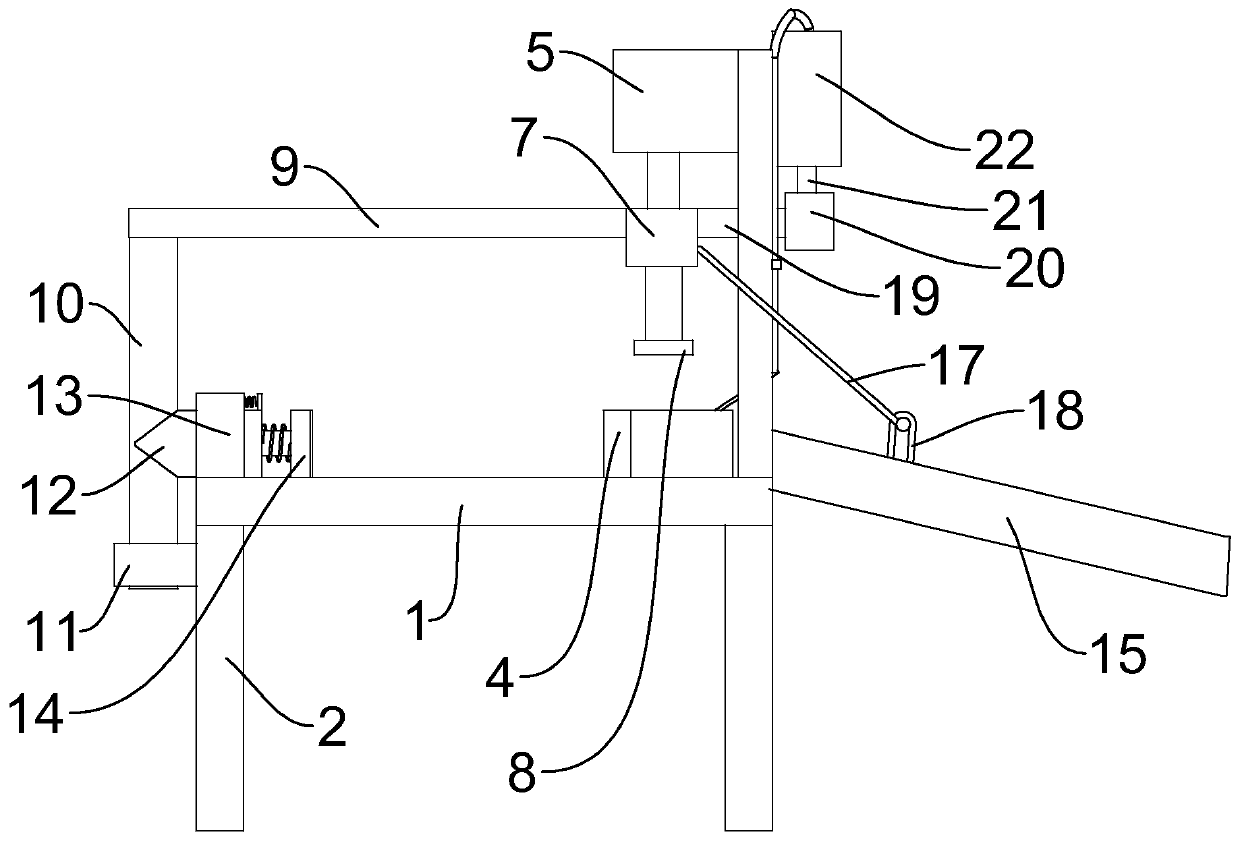

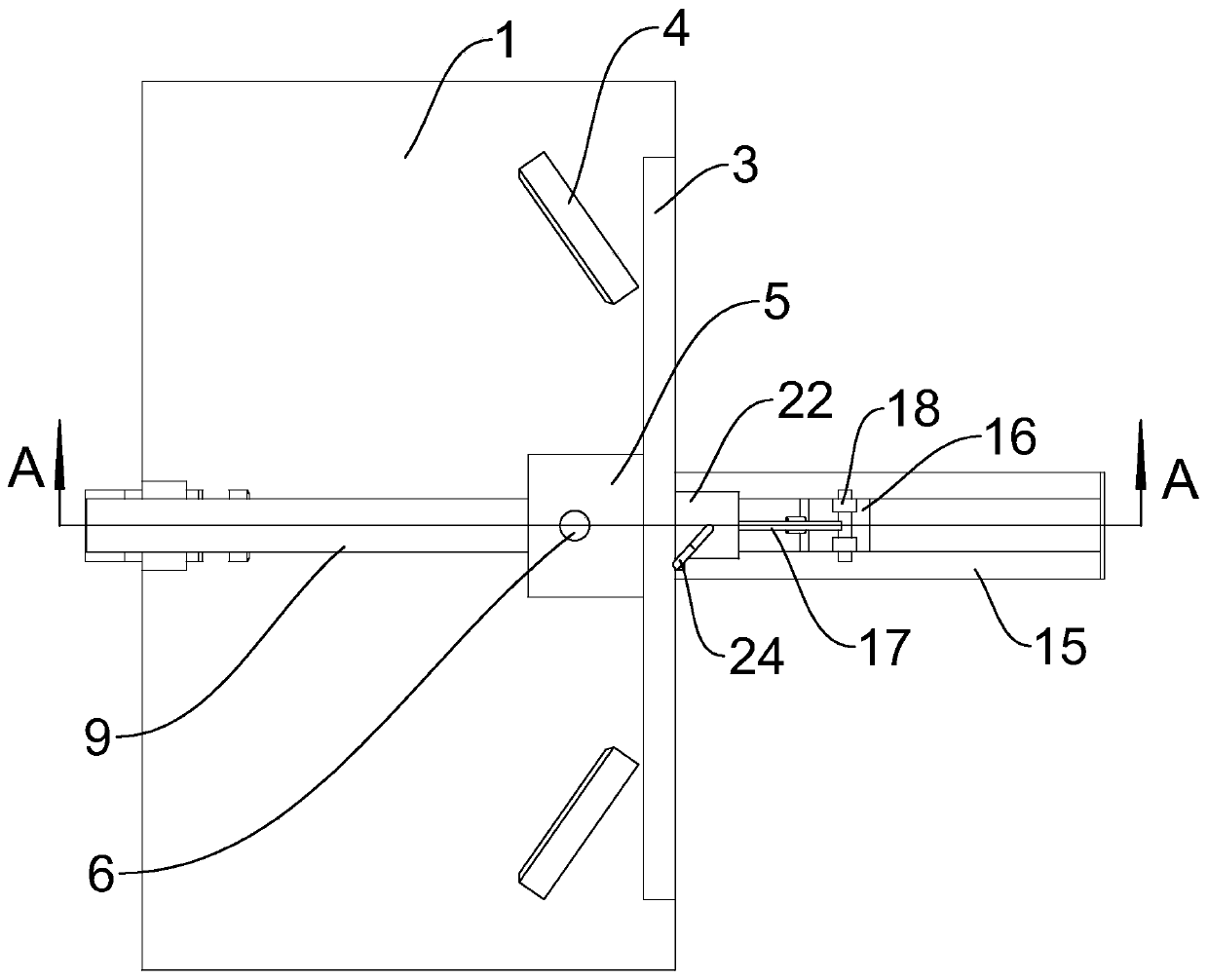

[0024] Such as Figure 1 to Figure 11 As shown, a processing device for a wooden tea tray includes a platform 1, the left and right sides of the lower end of the platform 1 are symmetrically provided with support plates 2, and the right side of the upper end of the platform 1 is provided with a vertical board 3 with a slot in the middle. 3. The right end of the platform 1 is provided with a ramp 15, and the front and rear ends of the ramp 15 are symmetrically provided with a chute 27, and the chute 27 is slid up and equipped with a second motor 16 arranged in parallel with the chute 27. The second motor 16 A drill bit 26 is keyed on the output shaft of the second motor 16. The front and rear sides of the se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap