Conveying belt deviation fault detection method based on image identification technology

A conveyor belt and image recognition technology, which is applied in the detection of conveyor belt deviation, conveyor belt deviation detection and automatic correction, to achieve the effect of saving sample collection costs, high accuracy and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

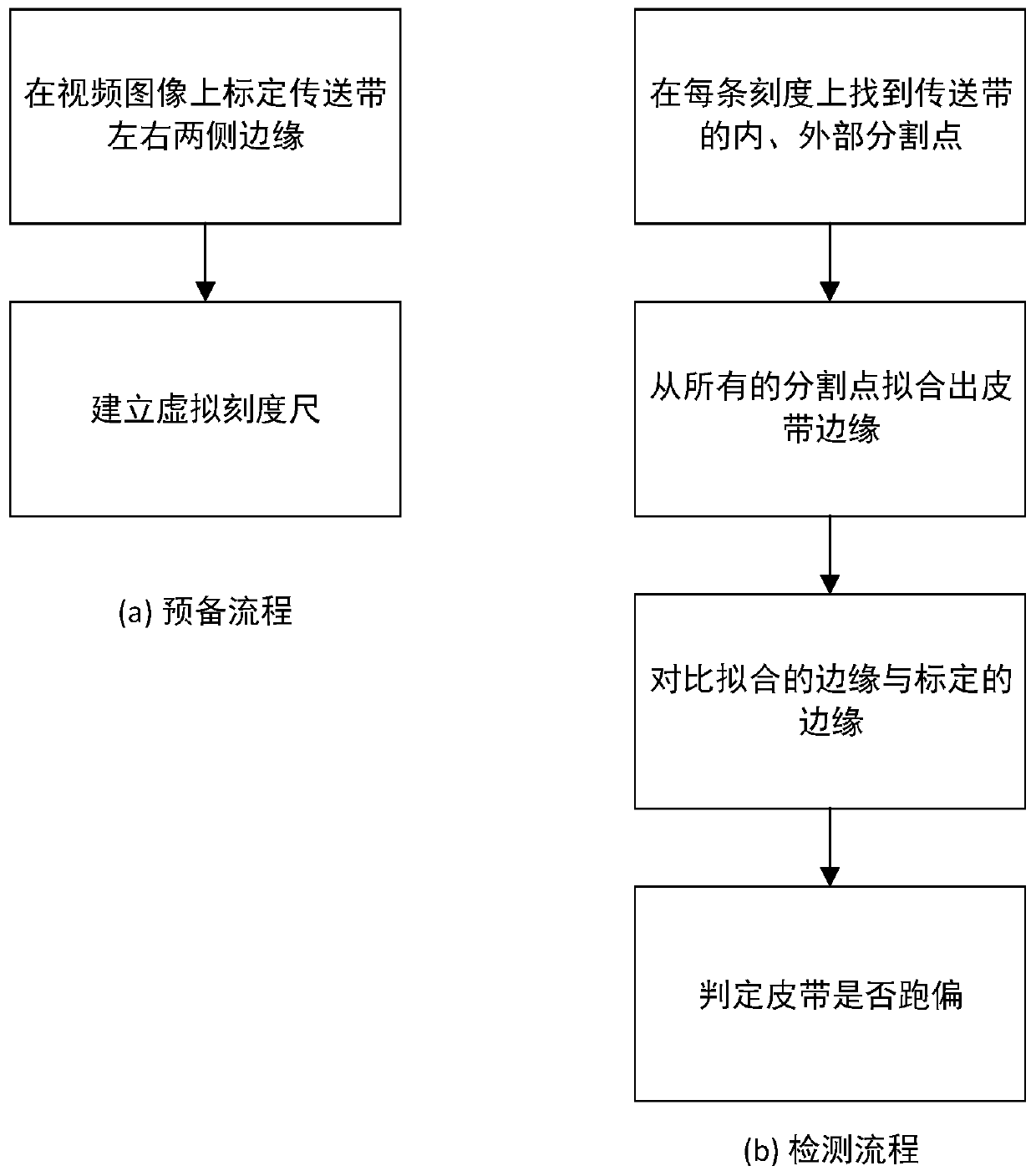

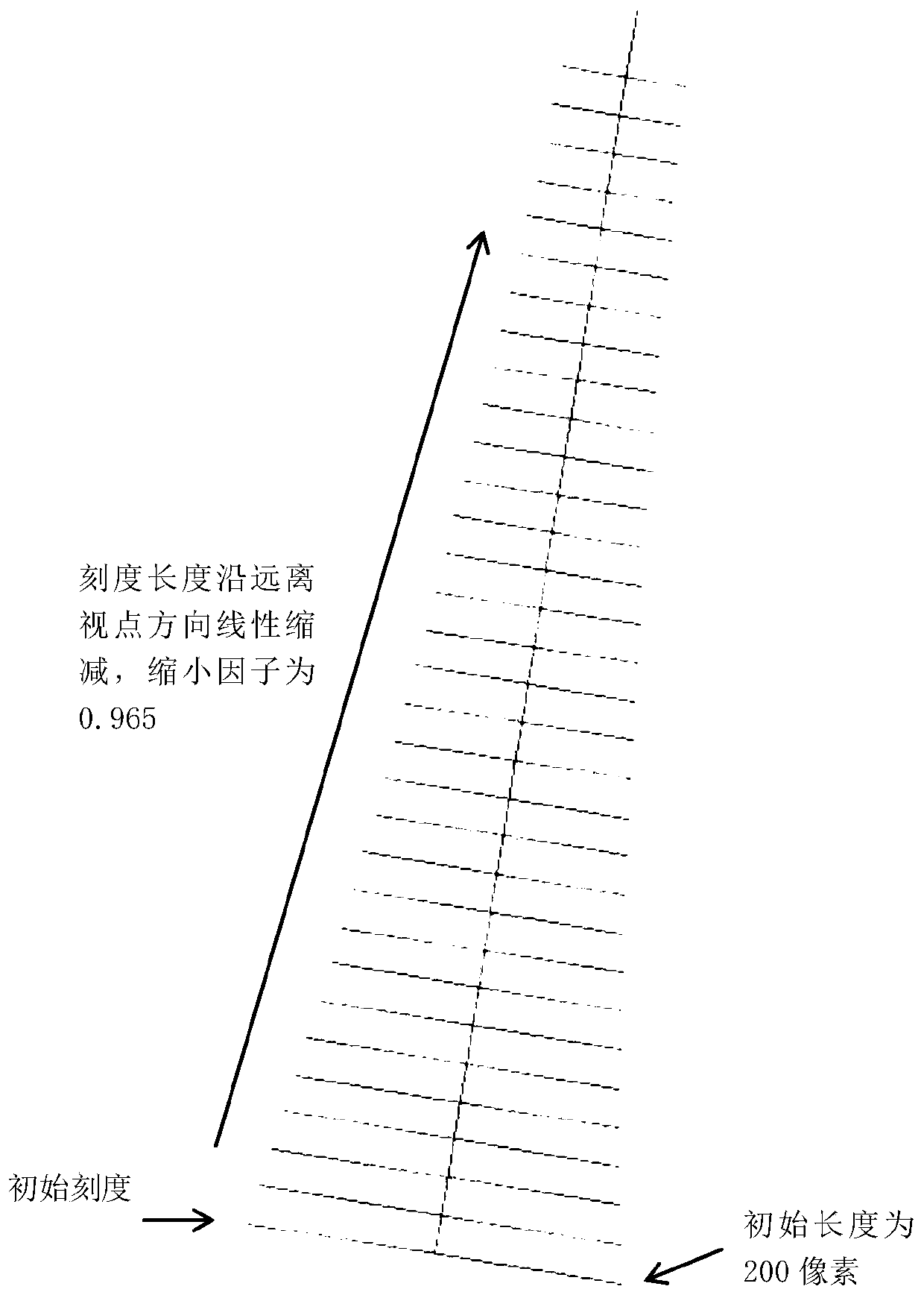

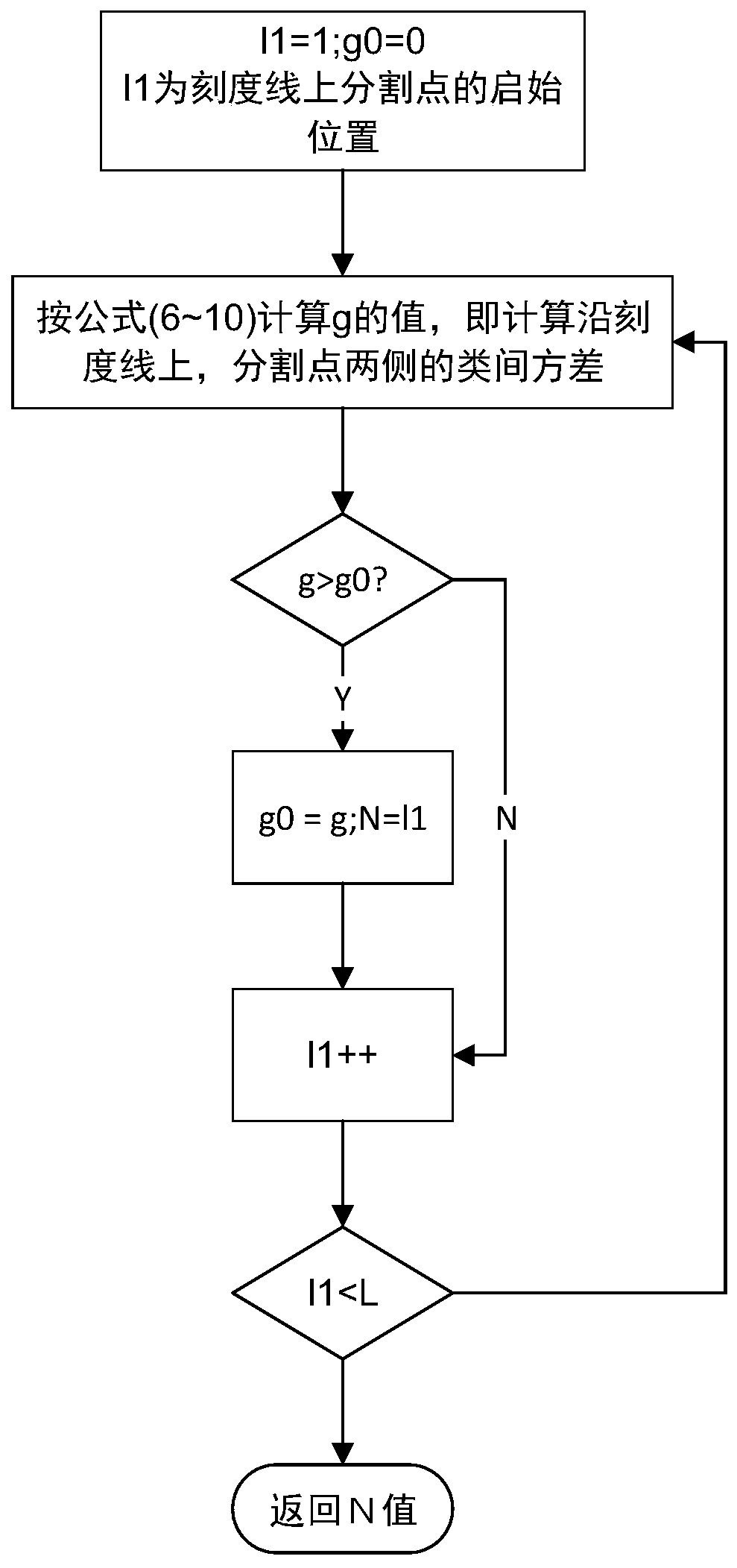

[0046] refer to figure 1 As shown, the present invention is based on the image recognition technology conveyor belt deviation fault detection method, comprising the following steps:

[0047] S1. Preparatory process:

[0048] S11. Collect images and calibrate the belt edge under normal operation of the conveyor belt;

[0049]In this embodiment, the monitoring equipment uses a bullet camera from Hikvision, and the output data format is a high-definition video with 1080*720 pixels. The data processing equipment adopts Nvidia's TX2 embedded processing board, which has a powerful GPU function and can process multiple channels of video data at the same time. The camera and the embedded processing board are connected by a router. After obtaining the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com