A Drilling Drawworks Valve Box Control System

A control system and valve box technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of damage control function and failure of electrical components, and achieve the effect of maintaining explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

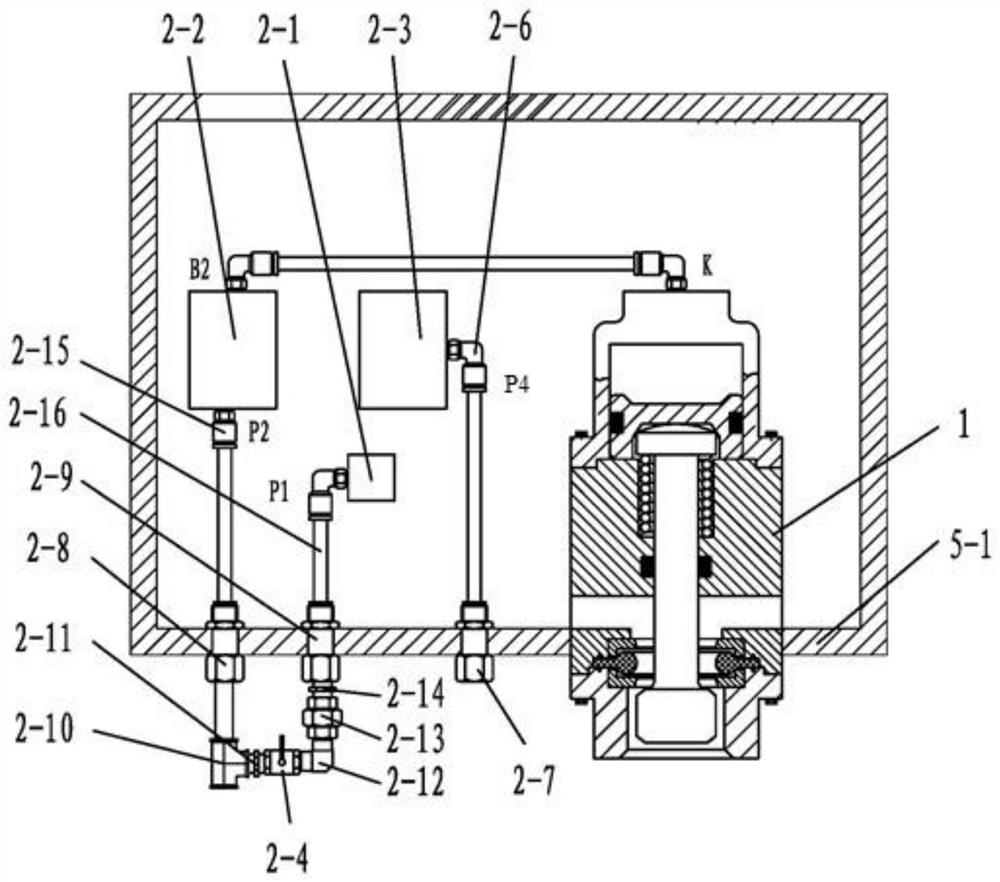

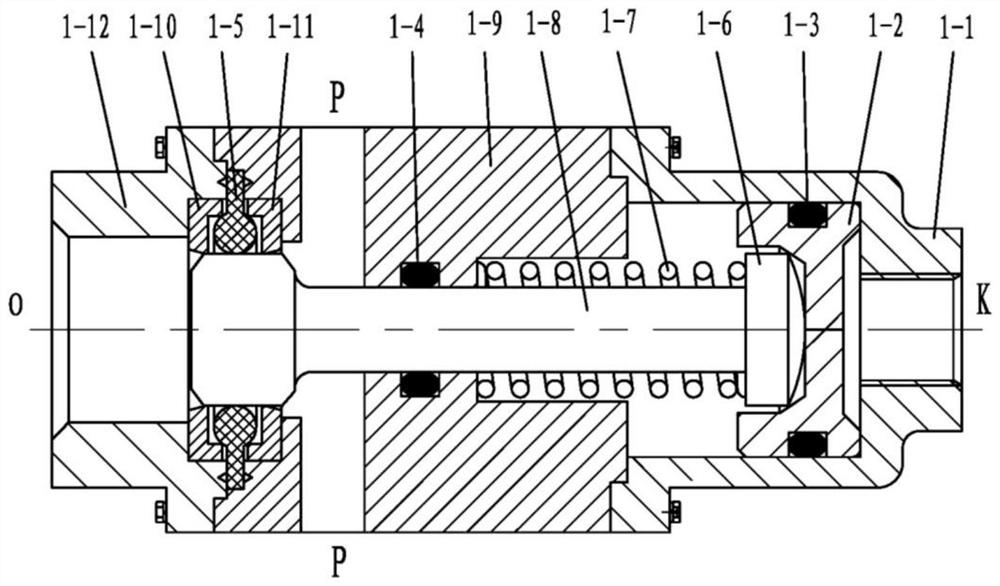

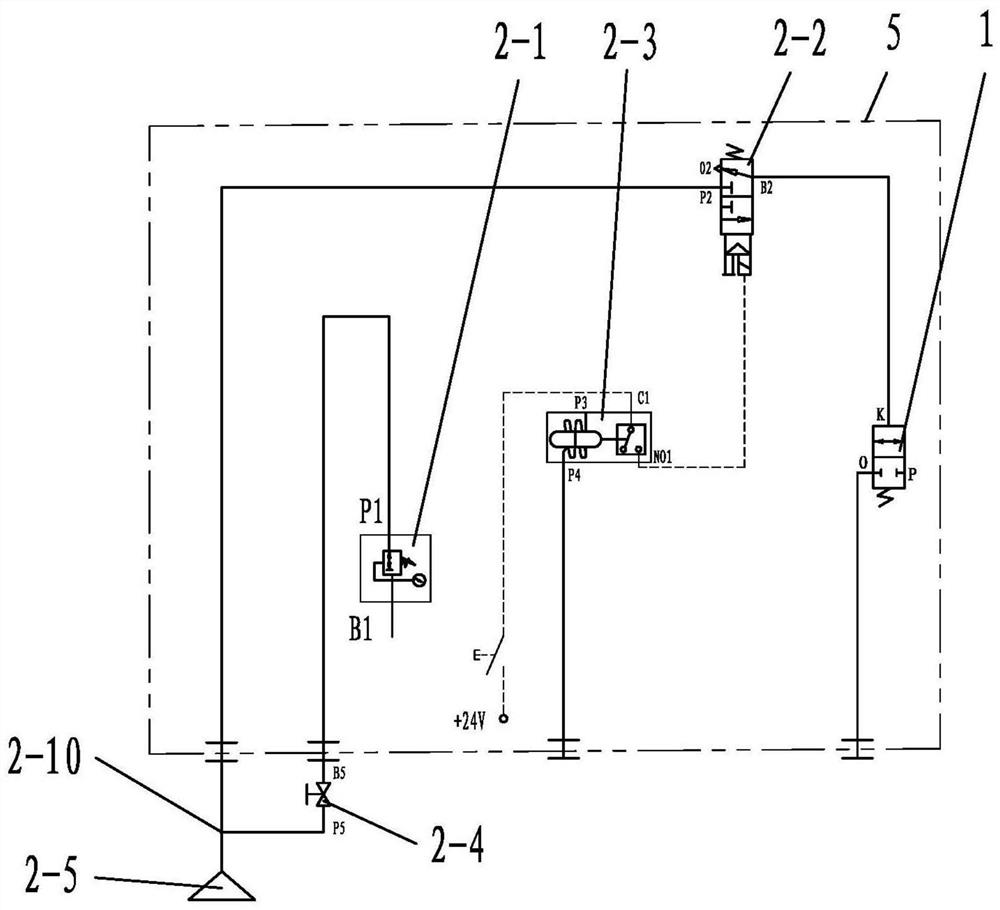

[0028] The invention provides a drilling winch valve box control system, such as figure 1 As shown, the drain valve 1 is installed vertically in the valve box 5, the lower edge of the drain inlet P on the middle cover 1-9 of the drain valve 1 is flush with the inner edge of the valve box bottom plate 5-1, and the middle cover 1-9 9 is welded with the inner and outer intersections of the valve box bottom plate 5-1, the drainage inlet P of the drain valve 1 is directly opened in the box body of the valve box 5, and the drainage outlet O of the drain valve 1 is opened outside the valve box 5 and connected to the atmosphere In communication, the fourth air inlet P4 of the differential pressure switch 2-3 is connected to the first wall joint 2-7 through the first pipeline joint 2-6, and the first wall joint 2-7 is connected to the inside and outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com