A kind of composite foam lightweight soil and preparation method thereof

A foam lightweight soil and composite technology, applied in the field of light soil, can solve the problems of being unsuitable for large-scale implementation, high production cost, and low strength value of foam light soil, achieving light weight, good thermal stability, Good effect of bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

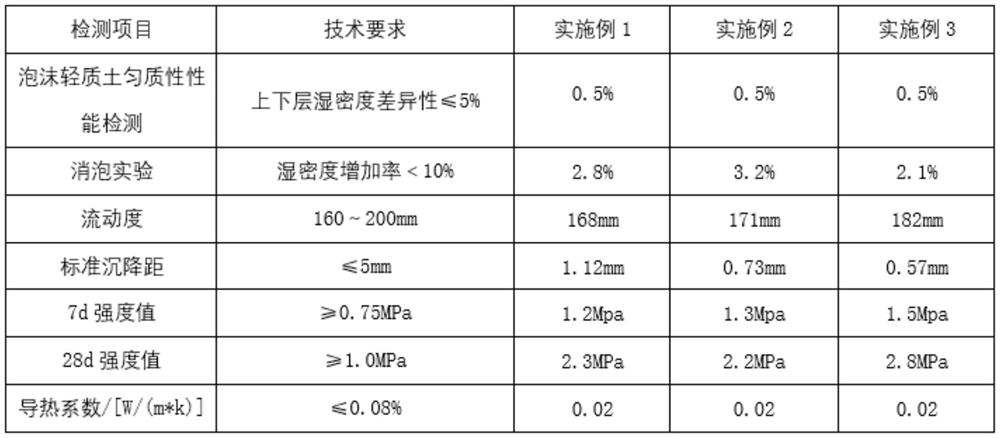

Examples

Embodiment 1

[0046] A composite foam lightweight soil specifically includes the following components in parts by weight: 100 parts of gelling material, 5 parts of foam foam, 1 part of reinforcing agent and 50 parts of water.

[0047] The cementitious material is composed of PO425 cement, slag powder, and high-calcium fly ash in a weight ratio of 5:1:2.

[0048] The reinforcing agent is obtained by mixing porous hollow glass microspheres with water.

[0049] Porous hollow glass microspheres are obtained by treating hollow glass microspheres with an acid solution.

[0050] Foaming foam is prepared by foaming agent and water according to the mass ratio of 1:20.

[0051] The foaming agent is obtained by mixing rosin modifier with polyvinylpyrrolidone and lauryl alcohol in a weight ratio of 80:13:6.

[0052] Wherein, the preparation method of rosin modifier is:

[0053] (1) Disposal of waste leather materials

[0054] Weigh the dried waste leather material and mix it with sodium hydroxide sol...

Embodiment 2

[0079] A composite foam lightweight soil specifically includes the following components in parts by weight: 100 parts of gelling material, 10 parts of foaming foam, 10 parts of reinforcing agent and 70 parts of water.

[0080] The cementitious material is composed of PO425 cement, slag powder, and calcium-increased fly ash in a weight ratio of 5:1:2.

[0081] The reinforcing agent is obtained by mixing porous hollow glass microspheres with water.

[0082] Porous hollow glass microspheres are obtained by treating hollow glass microspheres with an acid solution.

[0083] Foaming foam is prepared by foaming agent and water according to the mass ratio of 1:100.

[0084] The foaming agent is obtained by mixing rosin modifier with polyvinylpyrrolidone and lauryl alcohol in a weight ratio of 100:20:10.

[0085] Wherein, the preparation method of rosin modifier is:

[0086] (1) Disposal of waste leather materials

[0087] Weigh the dried waste leather material and mix it with sodi...

Embodiment 3

[0112] A composite foam lightweight soil specifically includes the following components in parts by weight: 100 parts of gelling material, 8 parts of foam foam, 5 parts of reinforcing agent and 60 parts of water.

[0113] The cementitious material is composed of PO425 cement, slag powder, and calcium-increased fly ash in a weight ratio of 5:1:2.

[0114] The reinforcing agent is obtained by mixing porous hollow glass microspheres with water.

[0115] Porous hollow glass microspheres are obtained by treating hollow glass microspheres with an acid solution.

[0116] The foaming foam is prepared by foaming agent and water according to the mass ratio of 1:20-100.

[0117] The foaming agent is obtained by mixing rosin modifier with polyvinylpyrrolidone and lauryl alcohol in a weight ratio of 90:15:8.

[0118] Wherein, the preparation method of rosin modifier is:

[0119] (1) Disposal of waste leather materials

[0120] Weigh the dried waste leather material and mix it with sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com