Preparation method of carboxylated carbon nanotube modified pentaerythritol acrolein resin

The technology of pentaerythritol acrolein resin and acrolein resin is applied in the field of preparation of energetic materials, which can solve the problems of lack of active groups, poor dispersibility, easy agglomeration, etc., and achieves the improvement of fiber toughening effect, section elongation, and section The effect of elongation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

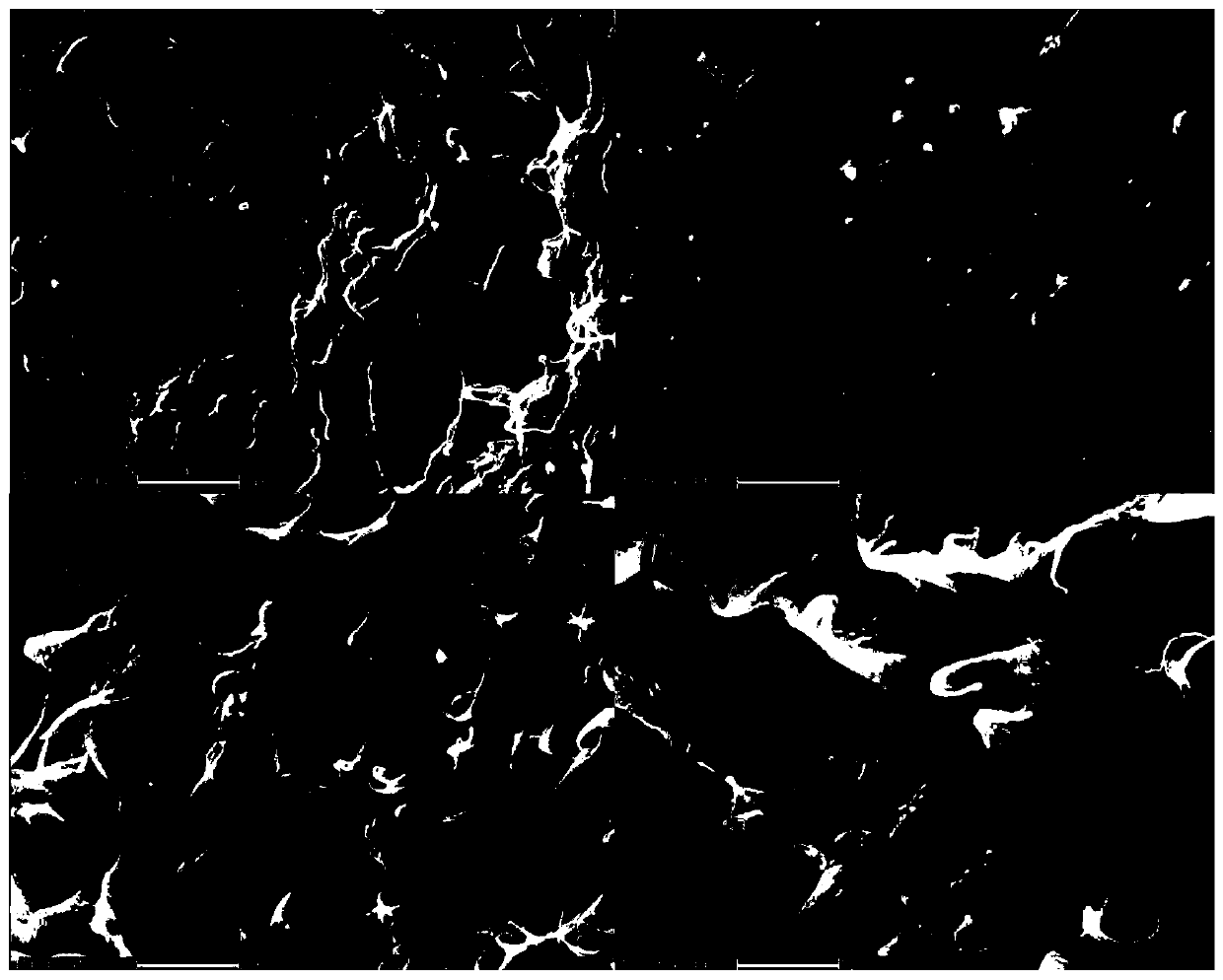

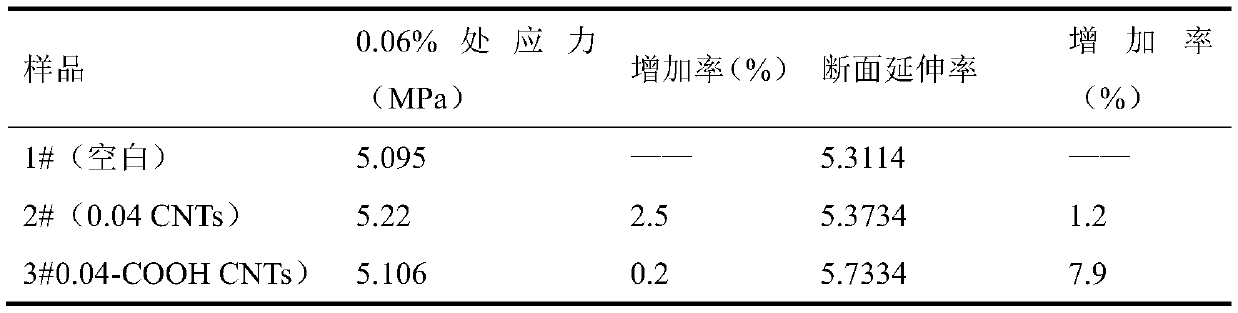

[0032] First weigh 0.02g of carboxylated CNTs, and use an agate grinding rod to crush and grind the CNTs; weigh 50g of 123 resin, then mix the ground CNTs with 123 resin, and initially stir evenly; Ultrasonic dispersion treatment for 30 minutes; mechanical stirring method was used again for 15 minutes; next, 0.9 mL of DES was added to the mixture, stirred evenly, and then poured into a mold; finally, it was placed in a 60°C oven and cured for 8 hours to prepare the Carboxylated CNTs modified 123 resin samples.

Embodiment 2

[0034] Weigh 0.04g of carboxylated CNTs, crush and grind the CNTs with an agate grinding rod; weigh 100g of 123 resin, then mix the ground CNTs with 123 resin, and initially stir evenly; then use an ultrasonic instrument to ultrasonicate the mixture Disperse for 30 minutes; again use mechanical stirring for 15 minutes; then add 1.8mL of DES to the mixture, stir evenly, and then pour it into a mold; finally put it in a 60°C oven and cure it for 8 hours to prepare carboxyl NaCNTs modified 123 resin samples.

Embodiment 3

[0036] Weigh 0.03g of carboxylated CNTs, crush and grind the CNTs with an agate grinding rod; weigh 100g of 123 resin, then mix the ground CNTs with 123 resin, and initially stir evenly; then use an ultrasonic instrument to ultrasonicate the mixture Disperse for 30 minutes; again use mechanical stirring for 15 minutes; then add 1.8mL of DES to the mixture, stir evenly, and then pour it into a mold; finally place it in a 60°C oven and cure for 8 hours to prepare 0.03 wt% carboxylated CNTs modified 123 resin samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com