Atmosphere printing and dyeing device for cloth

A kind of atmosphere and fabric technology, applied in the treatment of textile materials, spray/jet textile material treatment, textiles and papermaking, etc., can solve the problems of dye waste, inability to penetrate into fabrics, steam energy consumption, etc., to improve uniformity and avoid dyes Float around and prevent creases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

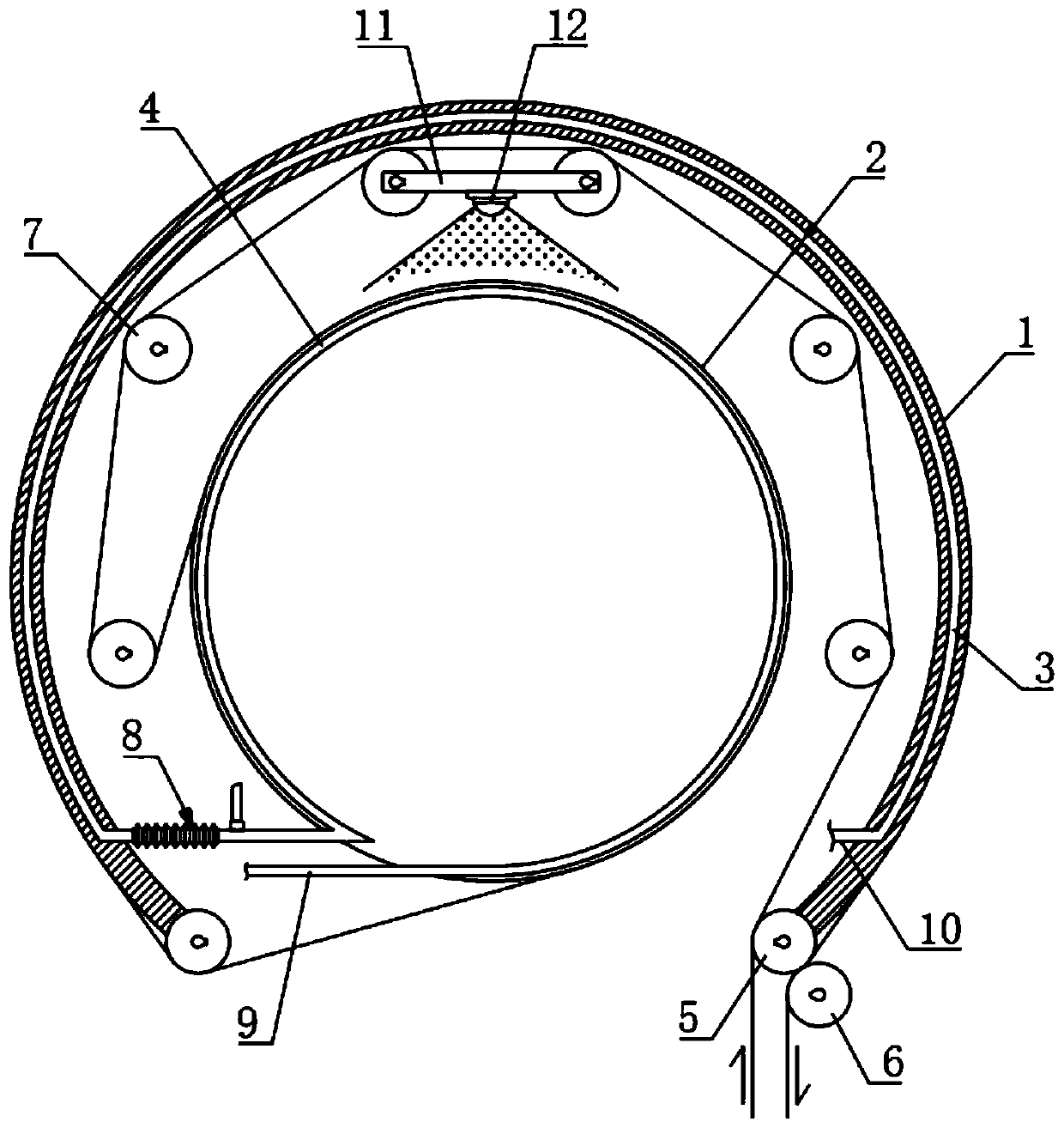

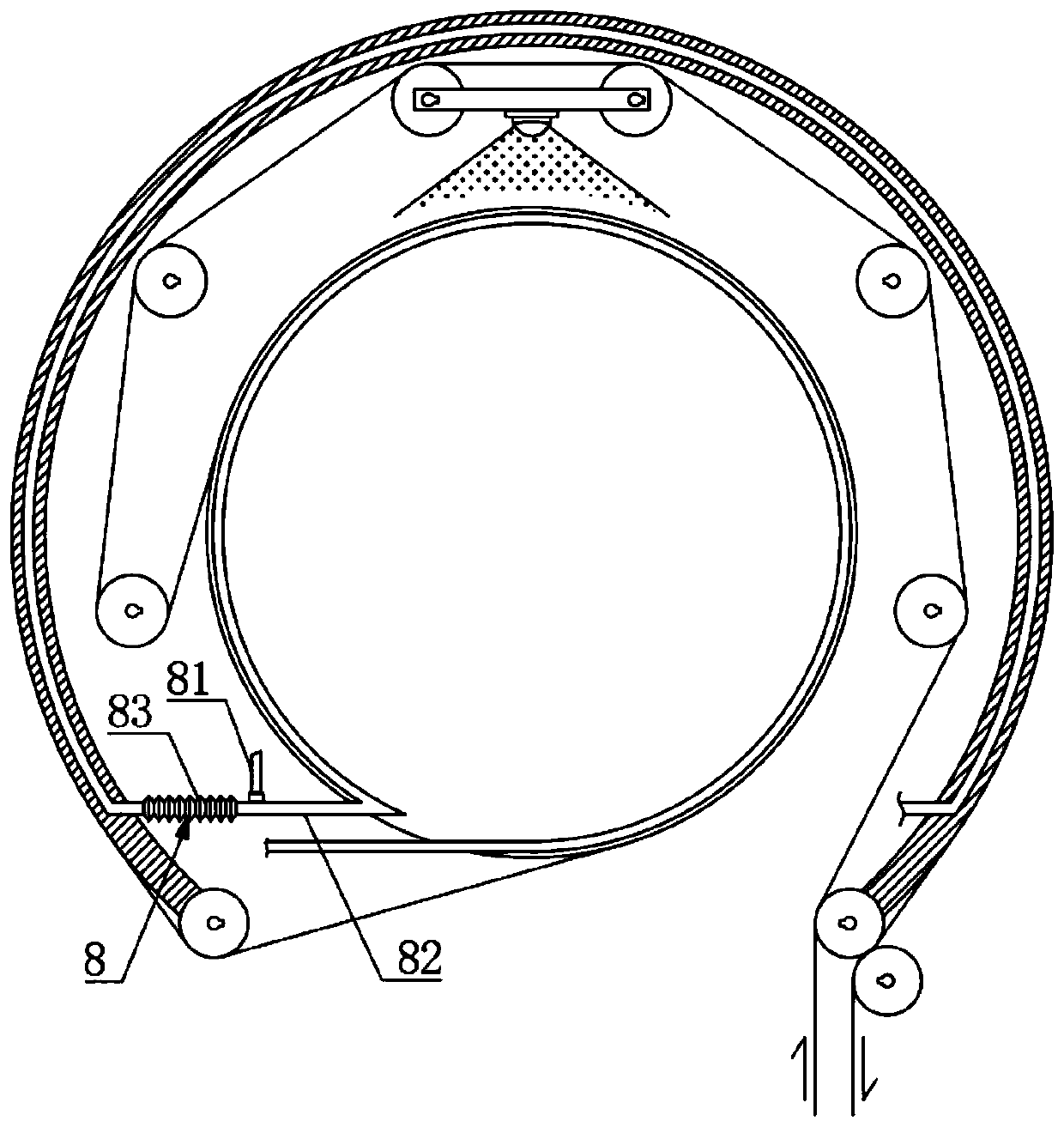

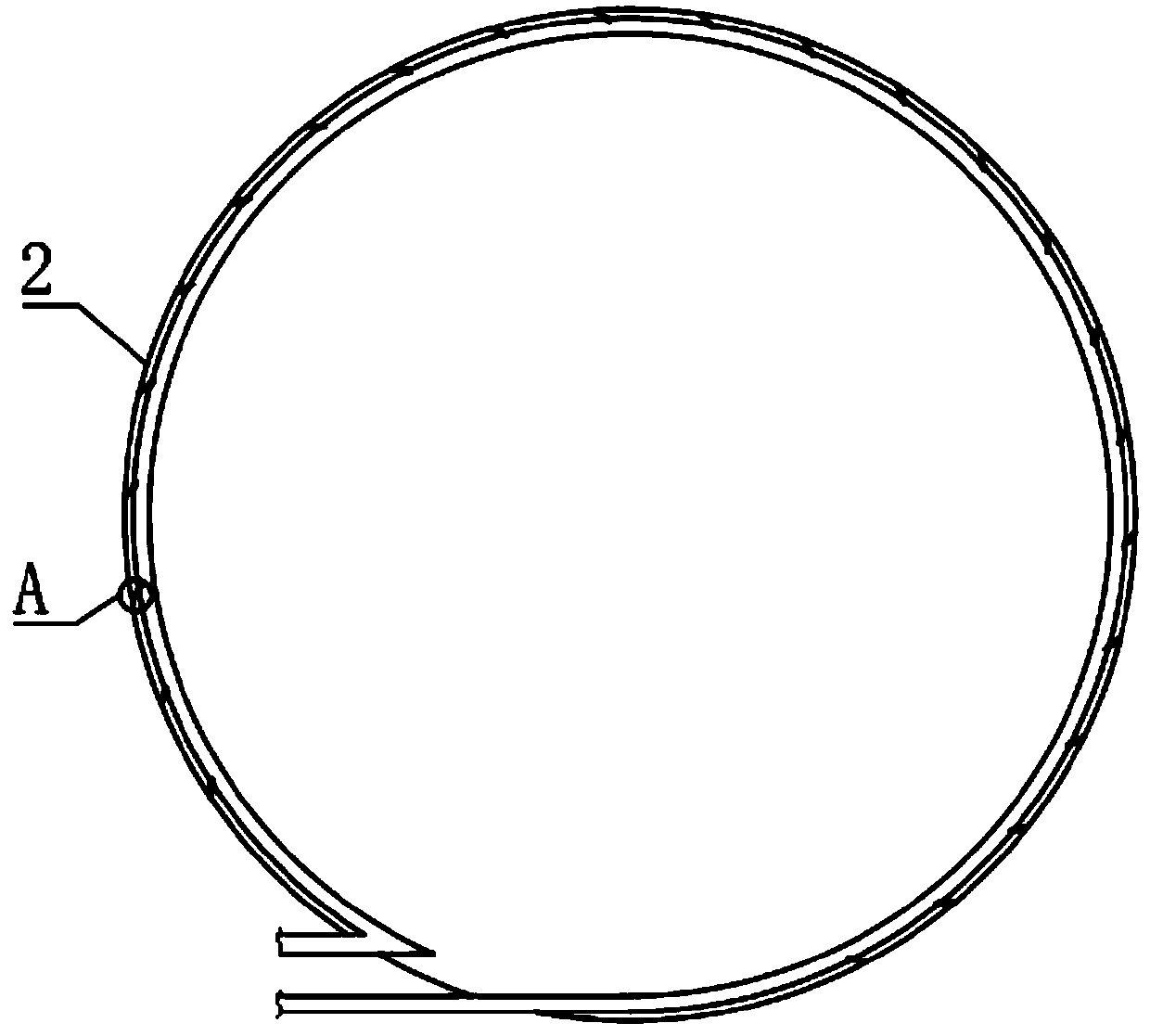

[0023] refer to Figure 1 to Figure 4 , including an outer cylinder 1 and an inner cylinder 2, the outer cylinder 1 adopts a hollow circular structure, the inner cylinder 2 is located at the axis of the outer cylinder 1, the bottom of the outer cylinder 1 is provided with a gap, and the two sides of the gap at the bottom of the outer cylinder 1 The first traction rollers 5 are arranged at each entity, and the periphery of one of the first traction rollers 5 is provided with a second traction roller 6 . A plurality of third traction rollers 7 are equidistantly arranged on the inner surface of the outer cylinder 1 , and the third traction rollers 7 are distributed in a semicircular array in the circumferential direction of the outer cylinder 1 .

[0024] The first traction roller 5, the second traction roller 6 and the third traction roller 7 play the role of guiding and stretching the cloth. For specific installation and movement directions, refer to figure 1 ,

[0025] A sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com